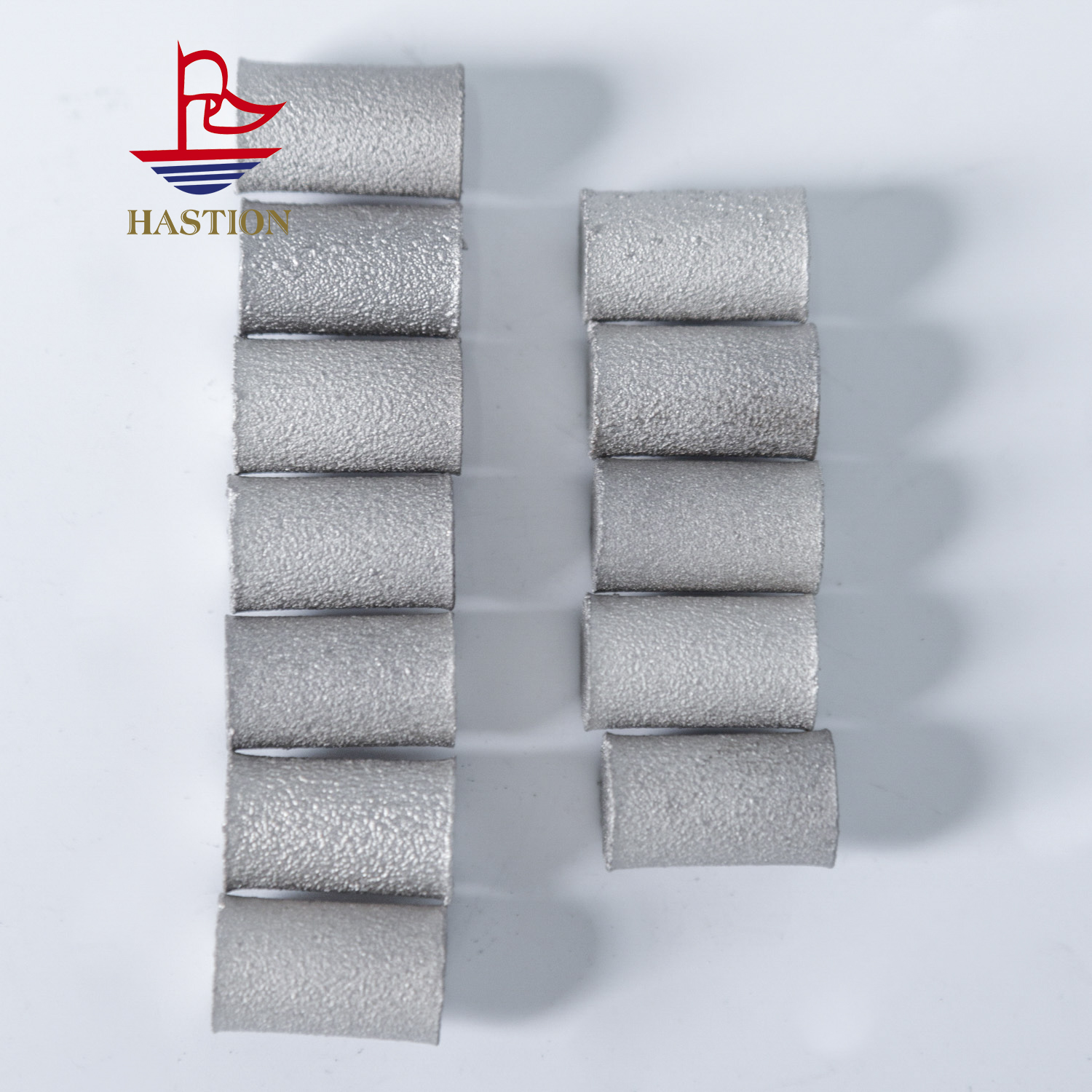

Low-carbon and environmentally friendly titanium carbide hard alloy rods

The production process of this titanium carbide round bar is strictly controlled, ranging from the selection of high-purity raw materials (titanium carbide powder with purity ≥99.5%) to the precise regulation of sintering temperature (approximately 1500℃), with each step significantly influencing the final performance. The finished product exhibits excellent dimensional stability. Within a temperature range of -50℃ to 300℃, its coefficient of thermal expansion is only 6×10⁻⁶/℃, which is considerably lower than that of metallic materials, ensuring dimensional accuracy of precision tools across diverse environmental conditions. It is widely employed as wear-resistant inserts in automotive molds, capable of enduring prolonged high-pressure friction with minimal wear, thereby extending mold service life. As a critical material in high-end manufacturing, titanium carbide round bars demonstrate superior corrosion resistance and are resistant to rust or degradation in humid, acidic, or alkaline environments. Additionally, its thermal conductivity is 15% higher than that of conventional tungsten carbide round bars, enabling rapid dissipation of heat generated during cutting and reducing the risk of thermal-induced tool wear. With a bending strength reaching up to 2500MPa, the material combines high hardness with a certain degree of toughness, effectively preventing fracture caused by impact during operation. In the aerospace industry, precision machining tools made from this material are commonly used for manufacturing engine components, meeting the stringent requirements of high-precision machining.

Other supplier products

|

|

Worry-free after-sales tungsten carbide guide wheel guide roller |

Guide roll (guide wheel) is the steel field bar, wire rod rolling equipment on the main consumption of spare parts, in the rolling process, to en... |

|

|

Protect the enterprise production carbide guide wheel |

Titanium carbide guide wheel is made of high hardness titanium carbide material, with excellent wear resistance, high temperature resistance and ... |

|

|

Titanium carbide guide wheel - hard alloy wear-resistant |

The installation holes of the guide wheel have high precision, and the fit clearance with the shaft can be controlled within 0.005-0.01mm, ensuring... |

|

|

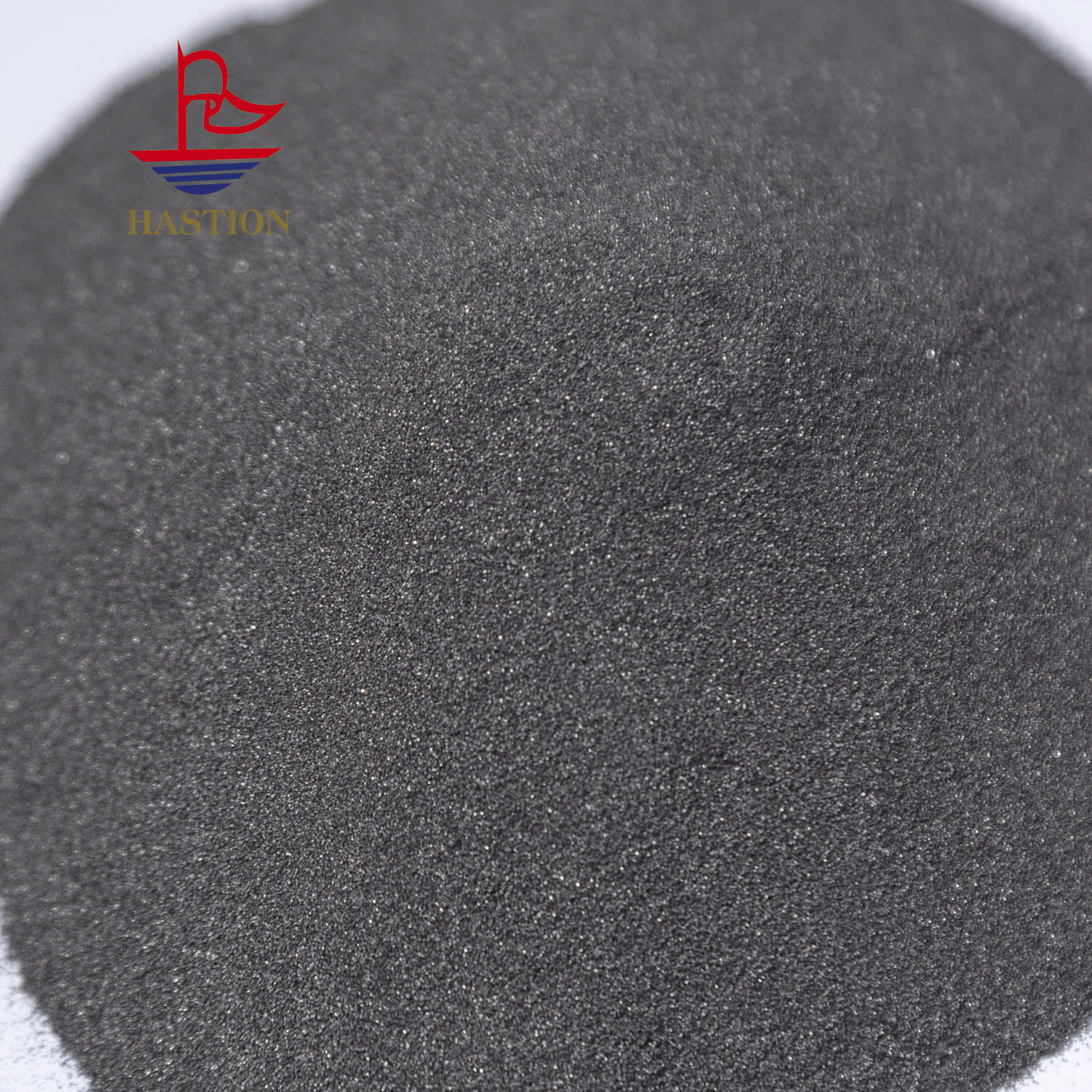

Factory direct sale titanium carbide powder |

Titanium Carbide TiC is an extremely hard (9-9.5 on the Mohs hardness scale) refractory ceramic material similar to tungsten carbide. It is a bla... |

|

|

Free Sample Chromium Carbide Powder |

Chromium carbide powder is gray-black in color, with high hardness, excellent abrasion resistance, high temperature and chemical corrosion resist... |

All supplier products

Same products