High pressure ibc tank washer, Automatic IBC washer

| Model | Semi-automatic ibc washer |

| Spray angle | 360° |

| Material | stainless steel |

| Max. Pressure | 5-500bar |

| Voltage | 220V/ 380V (or on request) |

| Medium | water or solvent |

| Temperature | 0-60°C |

| Configuration | high pressure pump and motor, water tank , filter, control box, ibc cleaning nozzle, hose, etc |

| Application | Rinsing and cleaning of IBC tote |

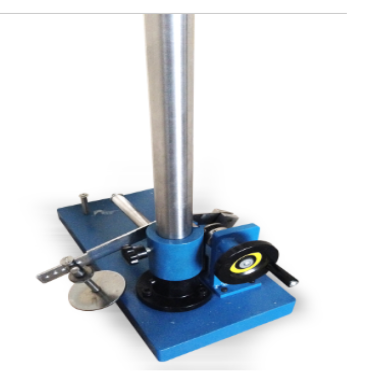

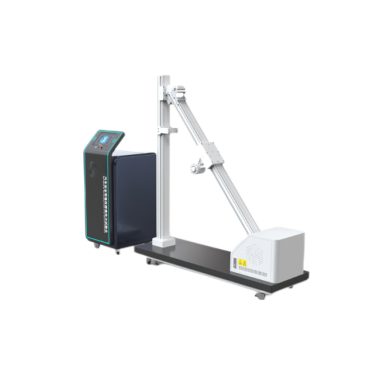

STDIBC tote washer offers quick and effective cleaning for ibc container or totes, commonly seen in modern production plants. The system is compact and mobile, making it easily transportable anywhere within a facility. With few parts and intuitive controls, the tote cleaning station is simple to install and operate.

It is designed to remove a variety of product residues from IBC totes, with the capability to remove thick or dried-on residues.

Unlike similar systems, the recirculation wash allows easy removal of oily residues using caustic chemicals. This system is designed to clean 275 and 330 gallon IBC totes with 200mm cover.

IBC tote washer can be used

to clean totes prior to shipment, to remove hazardous waste materials, and/or to prepare totes for sale.

Standard design

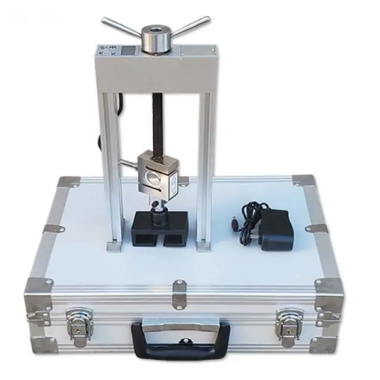

The STD tote cleaning station consists of all the necessary components for designed operation and installation. Included in this system is the Mobile pump station,pressure gauge,filter, pneumatic lifting mechanism, high pressure hose, pipe,and ibc cleaning nozzles.

Benefits

Fast: Cleans any drum in 2-6 minutes

Cleans the entire IBC tote, top and corners

Versatile, cleans a variety of residues

Quick ROI

Applications of tote cleaning station

IBC totes

In all industries

Residues

Latex, Paints, adhesives, chemicals

Coating

Petroleum products

Food and beverages products and ingredients

Pharmaceutical products and ingredients

Personal care products and ingredients

...and many more

Send product request

Other supplier products

| Carbon Black Dispersion Tester | Scope of application: DW1431 plastic carbon black dispersion measurement system is based on a professional image acquisition system and correspond... | |

| MST Medical Compression Stocking Tester | Product Overview TheMST Medical Compression Stocking Testeris a specialized instrument designed to evaluate the compression performance, elasticit... | |

| Textile moisture absorption and heat generation performance tester | Application ScopeThe textile moisture absorption and heat generation performance tester is a dedicated instrument for testing the moisture absorpti... | |

| Thermal Insulation Materials Adhesive Strength Tester | Meet the standard: JGJ144-2004 "External Wall insulation engineering Technical Regulations" JG158-2004 "Rubber powder polystyrene particles exter... | |

| Fleece Loop Length Tester | I. Product Overview TheFleece Loop Length Testeris a specialized instrument designed to measure the fiber loop length distribution in fleece fabri... |

Same products

| Seat Bumping and Creep Test Bench | Seller: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Seller: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Seller: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Seller: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Seller: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |