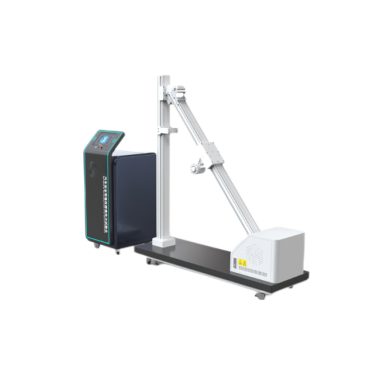

Air - tightness Testing Device for Automotive Connectors

The air - tightness testing device for automotive connectors uses the pressure principle to conduct non - destructive tightness tests on containers of various shapes, and can test products with air - tightness requirements in various industries (such as engine casings, oil pumps and automotive pipelines, valves, pipes, air pillows, outdoor electronic advertisements, water tanks, airbags, sealed workrooms, fire - fighting equipment, compressor pipelines, internal components of automobiles and motorcycles, battery casings, rubber hoses and connectors, etc.).

Standards:

ISO 6722. ISO 14572

Main Functions:

1. Provide stable positive and negative pressures for testing the air - tightness of seals or connectors.

2. The positive pressure value is digitally displayed and can be automatically controlled, while the negative pressure is controlled by a negative pressure pump.

Main Parameters:

1. Pressure gauge (-0.1 - 0.5MPa), digital pressure gauge, connecting air pipe, switch, pressure regulating valve

2. Three sets of connectors, with the diameters of the connecting pipes being 3. 5. 7 (in appropriate units) or as specified

3. Test water tank: 400mm×200mm×200mm

4. Timer: Can be set within the range of 0 - 999.9S/M/H

5. Positive pressure test: It can be pressurized according to the specified pressure, or according to the set program, such as pressurization at a level of 9.8KPa

6. Negative pressure test: Negative pressure of - 49Kpa (equipped with one negative pressure source with a maximum of - 89KPa)

7. Air source for positive pressure test: One silent compressor

Qinsun Instruments Co., LTD is a professional laboratory testing instrument manufacturer in China,Have been focusing on laboratory instrument R&D more than 30 years and have rich industry experience,Based on international testing standards,We are also the instrument supplier for BV SGS laboratory,We provide one-stop solutions for lab instruments,Free Training and Turn-Key Service,Products exported all over the world,Offer 36 month warranty and are a trustworthy partner.

Send product request

Other supplier products

| Car seat component clearance test bench Degree of automation: | Applicable standards: Car seat component clearance test benches usually follow the following domestic and international standards: QC/T 805-2008"... | |

| Capillary rheometer | Standard: DIN 54811. ASTM D 3835. ISO 11443 Application: 1. It is suitable for measuring the shear rate of plastics and polymer materials and th... | |

| High-Power Lamp tube (1500W~12000W) | Applicable Standards High-power lamp tubes adhere to global safety and performance benchmarks, including: IEC 60598-1(Luminaires – Genera... | |

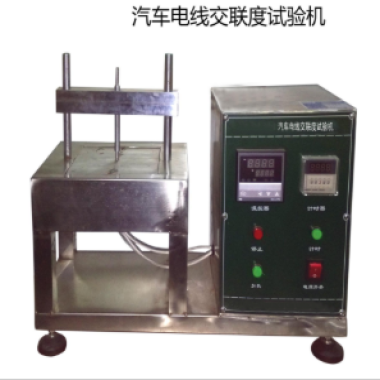

| Automobile Wire Cross-linking Test Device | Applicable Standards: SAE J1128 - 2005 and other standards Main Parameters: 1. Test rod: Φ6mm, 300mm in length 2. Hot plate specification: ... | |

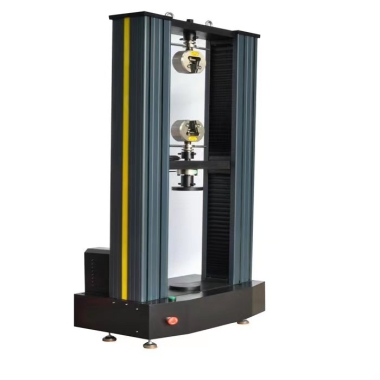

| Electronic single fiber strength meter | Compliance Standards - GB/T14337 - GB/T9997 - GB/T13835.5 - GB/T21120 - ISO5079 - ISO11566 - ASTM D3822 - BS4029 Application Scope - Used... |

Same products

| Seat Bumping and Creep Test Bench | Seller: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Seller: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Seller: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Seller: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Seller: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |