Drill Pipe Magnetic Flux Leakage Detector MFL-308

Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so

Detection speed: 6-20 m / min

Acceptance criteria: American Petroleum Institute API testing standards

The main MFI magnetic flux leakage inspectionmethod principle is that the workpiece is magnetized (close to saturation) to have a certain magnetic flux density to generate a leakage magnetic field at the discontinuity, and the magnetic field sensor sends the output signal to the operational amplifier.

Due to the magnetic saturation state, the workpiece has a relatively high magnetic field strength and magnetic field density, and the magnetic lines of force are not limited so that the surface of the workpiece has a large magnetic leakage, which is favorable for on-site detection.

The magnetic sensitive sensor scans along the surface of the magnetized ferromagnetic material, pick up the defect leakage magnetic field and forms a defect electrical signal to achieve the purpose of finding the defect position and parameters.

Magnetic flux leakage non-destructive inspection technology is widely used in the detection of metal materials and the evaluation of related products due to its fast detection speed, high reliability and low surface cleanliness. Different from magnetic particle detection and detection, the signal in magnetic flux leakage detection is not displayed by magnetic powder, and it has no pollution to the environment: due to various sensitive components (such as Hall element and coil method), the detection result is directly output by electric signal, which is easy to connect with computer to realize digital Processing, so the detection results can be stored and reproduced, facilitating the analysis of the detection signal and the trend analysis of the detection results.

Drill Pipe Magnetic Flux Leakage Detector MFL-308 Performance

|

Drill pipe inspection method |

Drill pipe straight ahead, test assembly fixed |

|

Detection range |

F60-F168drill pipe |

|

transport system speed |

6-20m/min;variable frequency range |

|

Testing methods |

Automatic charging, Automatic testing, Automatic sorting |

|

The sensitivity of hole detection |

|

|

Accuracy of section area measurement |

2-4% |

|

Position resolution accuracy |

20mm |

|

Non-detection zone |

£100mm(drill pipe body) |

|

False alarm rate |

£0.5% |

|

Remaining magnetism after demagnetization |

£10GS |

|

The internal and external surface coverage |

100% |

|

Equipment usage environment |

Working temperature:40°-minus50°; Working humidity:0-95%; |

BKN is a professuonal mfl suppliers, we provide ndt device, magnetic flux inspection, mfl sensor, magnetic pipeline inspection services,eddy current testing, etc. Want to know more? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

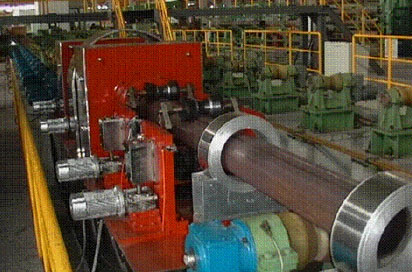

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

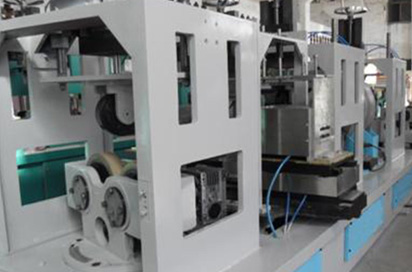

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testing system is a full automatic crack hardness sorter that integrates light, electricity and machinery. The w... | |

| Eddy Current Testing Equipment | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... | |

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing (BKNET-101) is a fully automated eddy current inspection systemthat uses large-scale imported integrated circuits combined... |

Похожие товары

| YC160W Wheel excavator YC160W | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |