Steel Bar Testing

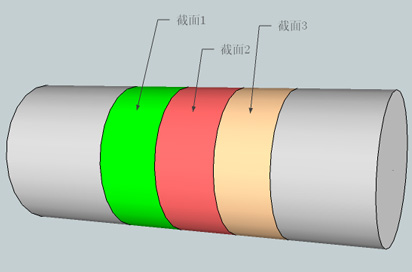

The steel bar is rolled by a rolling mill and produce both surface defects and internal defects during the rolling process. The internal defect is that the original defects of the steel chain or billet are extended during the rolling process. These defects are mainly concentrated in the central part of the steel rod. The forms mainly include slag inclusion, shrinkage, delamination, and looseness. The amount of rolling deformation increases and increases. In actual production, these internal defects of the steel rod have a serious impact on the performance of the steel. For example, steel rods used for forging, these internal defects will continue to exist inside the steel rod during the forging process, and some will continue to extend. Some will form a mezzanine. Therefore, the non-destructive testing of the internal defects of steel bars has attracted more and more attention.

Ultrasonic automatic detection system for steel bars

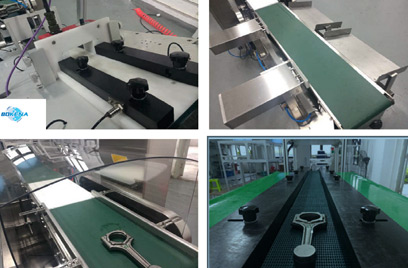

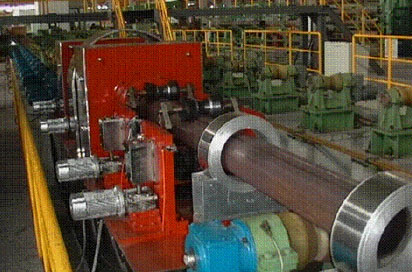

The ultrasonic automatic detection system for steel bars is a device that uses ultrasonic longitudinal wave detection to detect defects such as delamination and inclusions inside the steel bar. The steel rod enters a six-way ultrasonic probe that rotates at a high speed through a communication mechanism, and each channel is set to a different frequency. The steel rod advances at a low speed, so it can cover 100% of the surface of the steel rod. After the steel rod enters the ultrasonic system, the system begins to detect.

When a defect is detected, the probe will feed back the defect signal. The defect signal is processed, amplified, converted to the oscilloscope, and the oscilloscope is transmitted to the computer. The program in the computer responds accordingly, that is, the defect location is identified. In the subsequent production, the marked steel bar will be cut off, thereby avoiding the quality problems caused by the internal defects of the steel bar.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

BKNis one of the best ultrasonic testing equipment manufacturers,we have ndt ultrasonic testing equipment,ultrasonic testing of steel barsand steel bar test,RFQ today.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless.... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Drill Pipe Magnetic Flux Leakage Detector MFL-308 | Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so Detection speed: 6-20 m / min Acceptance criteria: American Petroleum Institute ... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from the main body of the computer mechanism the handle o... | |

| Wireless Transmission Steel Bar Ultrasonic Flaw Detector | Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external ... |

Похожие товары

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Продавец: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Продавец: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Продавец: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Продавец: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |