High speed conventional heavy duty lathe price

High speed conventional heavy duty lathe price

This machine tool belongs to heavy machine tool,the maximum weight is 16 tons, adopt the rectangular guide rail, can be able to cut the end section of all kinds of parts,outer circle, inner hole and metric system, English system, modulus, state thread.

Main configuration:

StandardConfiguration:

1. Bed rail width 1100,Two top-load bearing 16 tons

Optionalconfigure:

1. Double saddle add another 80,000.

2. Roller additional price of 25,000 yuan

|

UNIT |

C61180 |

||

|

CAPACITIES |

Swing over bed |

mm |

1800 |

|

Swing over carriage |

mm |

1450 |

|

|

Max.length of workpiece |

mm |

3000-12000 |

|

|

Max.turning length |

mm |

2800-11800 |

|

|

Pan of guideway |

mm |

1100 |

|

|

Spindle nose |

mm |

A2-15 |

|

|

Spindle bore |

mm |

100 |

|

|

Taper hole of spindle |

Metric140 |

||

|

Range of spindle speeds |

r/min |

Forward:3.15~315;Reverse:3.5~291 |

|

|

SPINDLE |

No.of spindle speeds |

Forward:21; Reverse:12 |

|

|

No.of Longitudinal and cross |

56/56 |

||

|

Feed per revolution |

mm |

Longitudinal:0.1~12;Transverse:0.05~6;Up turret:0.025~3 |

|

|

No. and range of metric thread |

44;1~120mm |

||

|

No. and range of inch thread |

31;28~1/4″ |

||

|

No. and range of module thread |

45;0.5~60mm |

||

|

TAILSTOCK |

No. and range of dia. thread |

38;1/2~56DP |

|

|

Distance of centerline and tool resting plane |

mm |

53 |

|

|

Tool post swing range |

° |

±90° |

|

|

Max.travel of cross slide |

mm |

900 |

|

|

Max.travel of top slide |

mm |

360 |

|

|

Section of tool shank |

mm |

50(380x380) |

|

|

Travel of tool post (per turn of dials) |

mm |

0.05(0.002″) |

|

|

OTHERS |

Dia. of tailstock |

mm |

260 |

|

Travel of tailstock quill |

mm |

300(12″) |

|

|

Taper hole of tailstock quill |

Metric80 |

||

|

Main motor power |

kw |

30 |

|

|

Length |

mm |

6120-15120 |

|

|

Width |

mm |

2058-2580 |

|

|

|

Max.weight of workpiece |

t |

16 |

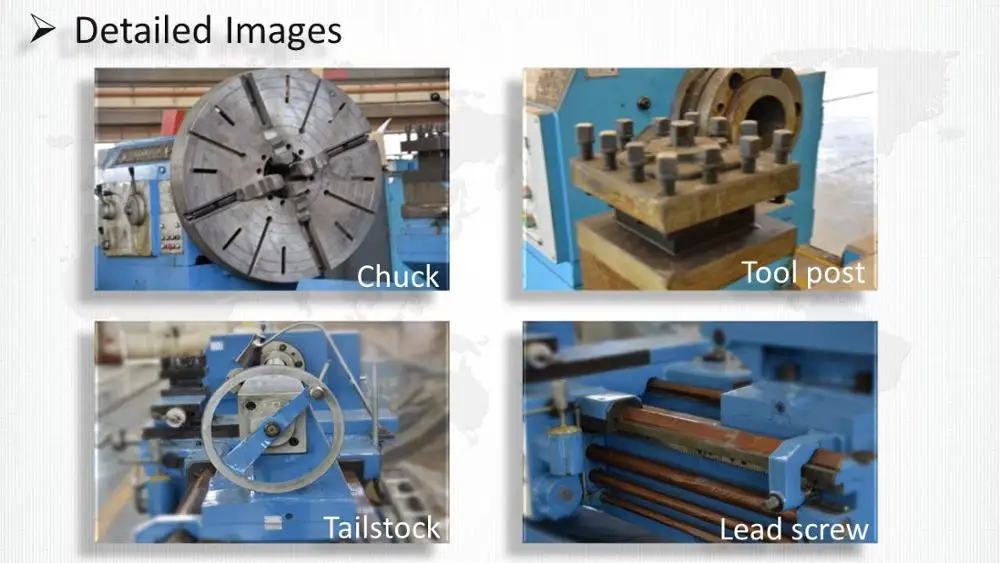

When the gear and gear ring are engaged, the four locking claws are connected, synchronously and at the same time, can hold the circular workpiece.When the gear and gear ring are separated, the four claws are independent, which are the same as the original four-jaw chuck.

Tail frame:mounted on the bed guide rail and moved vertically along this guide rail to adjust its position. The tail frame is mainly used to install the top, to support the long work piece, also can install the drill bit, reamer and so on the hole processing.

1. FOB Shanghai / Tianjin or CIF, LCL or FCL shipping.

2. Payment terms: T/T or other ways contact us.

3. Package: standard wooden case

4. Delivery time: Within 20 working days after the down payment. (Actual delivery time depends on actual order.

2. Check the acceptance

Receive machine,please check:

1. Examine the content of the packing list,the product quantity to both consistent,and accessories;

2. Machine tool details if they 're normal, If have the trace of replacement and maintenance, If have other effects use of the problem.

If happens above declare,please contact us immediately.

Send product request

Other supplier products

| tube forming press for Upset Forging of sucker rod | DRILL PIPE PRODUCTION LINE: The production line for the processing and production of oil drilling pipe, is mainly divided into three steps, by usi... | |

| High speed conventional heavy duty lathe price | High speed conventional heavy duty lathe price This machine tool belongs to heavy machine tool,the maximum weight is 16 tons, adopt the rectangul... | |

| Homemade new Dia. of spindle hole 130mm spherical turning lathe on sale | Homemade new C6595 Dia. of spindle hole 130mm spherical turning lathe on sale The spherical lathe is mainly used for the turning machining of sp... | |

| tubular upsetting equipments for Upset Forging of Oil Extraction casing | DRILL PIPE PRODUCTION LINE: The production line for the processing and production of oil drilling pipe, is mainly divided into three steps, by usi... | |

| Chinese high speed precision cnc lathe for sale | Chinese high speed precision cnc lathe for sale These series are economical CNC horizontal lathe, which are not only suitable for automobiles, tr... |

Same products

| Point Rails Lowering Value Measuring Ruler | Seller: 842518 | The frog vertical wear measuring ruler is used to measure the vertical wear value at any part of ... | |

| Portable Laser Alignment Device | Seller: 842518 | Laser Alignment Device is used for measuring track level and line to aid track measurement and ha... | |

| Rail cant measurement device | Seller: 842518 | The main part of the wheel tread is an inward inclination of 1:40 . In order to make the top of t... | |

| NGM-6.3II Internal Combustion Rail Grinding Machine | Seller: 842518 | This machine is mainly used for the recovery and grinding of welded joints,calendering burrs,rail... | |

| NCM-5.1 Internal Combustion Turnout Grinding Machine | Seller: 842518 | NCM-5.1 frog and switch grinder is specifically designed for grinding operations through switch a... |