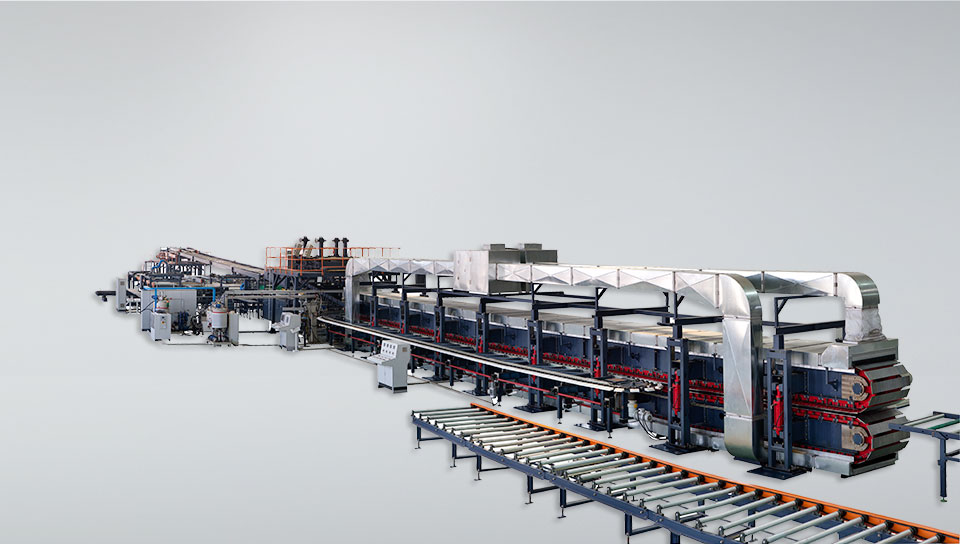

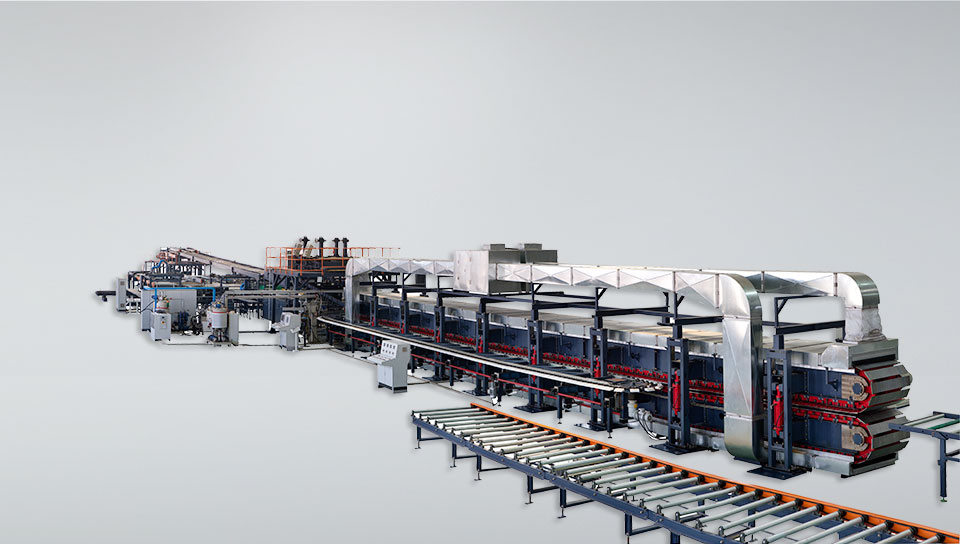

H-Beam Welding Line

Beam welding line machineconsists of an assembling machine, front welding machine, turn-over device, back welding machine and the transmission conveyors. It is used to assemble the H-beam,180°turn-over and transmit, etc. The annual welding capacity is 8000 tons. The Max welding speed can reach about 2m/min.Regularly, we adopt Lincoln welding machine (DC-1000) and NA-5 control system.

JH-150A h beam welding linefor H-profile steel is a wonderful technical product that integrates mechanical, electric, and pneumatic technologies. The machine, using advanced technology of single-arc double-wire welding, greatly increases the production efficiency.

The half line and whole line of H-Beam Welding Line Machine are different. The whole production line includes the turnover device and a second welder and it's related roller conveyor, while the half production line doesn't include the above-mentioned parts.

Video of H-Beam Welding Line

H-beam welding line, which is developed by Zhejiang Jinggong Science and Technology Co., Ltd., achieves the quality production of H-beam. It's the most advanced H-beam equipment domestically. H-beam welding line consists of the assembling machine, main welder, turnover device, and conveyor, etc.

H-beam welding line is very well received and widely applied by most steel structural enterprises for its high efficiency, big production scope, easy operation, and small space, etc.

Size Of Raw Materials Required For H-Beam Welding Line

Web height: 250-1500mm

Web thickness: 3-12mm

Flange width: 150-500mm

Flange thickness: 5-25mm

Length suitable workpiece: 2000~15000mm

Components of H-Beam Welding Line

Assembly Machine

The assembly machine is the first stage before entering the main welder. Before entering the main welder, the web plate and flange plate are to be assembled. By stop welding the two heads of the workpiece, H-beam assembling can be completed to go on the next stage.

Main Welding Machine

The main welding machine is the main equipment for this production line. After the assembled three plates are fed to the main welder through the conveyor, the welding process is started, and through positioning, clamping, and adjustment, until the whole process is completed.

Turnover Device

he turnover device is the assisting equipment of H-beam welding, one side welded H-beam will be transported to turn over device through the conveyor, and to turn over about 180 degrees, and to go on through conveyor to the main welder for welding the other side.

Compared with the traditional welding line, the H-beam welding line has the following seven advantages:

If you want to know more about jinggong,please visit our website.

在线联系供应商

Other supplier products

| Rockwool Continuous Sandwich Panel Production Line | The rockwool sandwich panel production lineis one continuous and automatic line that integrates mechanism, electrical controlling, hydraulic system... | |

| Roll Forming Machine | Having made automatic china roll formerfor over twenty years, we are a professional china roll forming machine factoryin this area with rich experi... | |

| Basic Situation of the Building Materials Machinery Industry | Ⅰ. Basic situation of the industry economy In the face of fierce market competition, the building materials machineryindustry has seen positive ... | |

| Slitter | Our slitting machine is the auxiliary equipment used for slitting materials for roll forming machines. It is simple in structure and easy to adjust... | |

| Basic Situation of the Building Materials Machinery Industry | Ⅰ. Basic situation of the industry economy In the face of fierce market competition, the building materials machineryindustry has seen positive a... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |