Edge Rolling Parts

Edge rolling, we can also call it bending roll round, which is a method to put the sheet metal bending into the nearly closed cylinder forming. It belongs to a kind of metal cold bending.

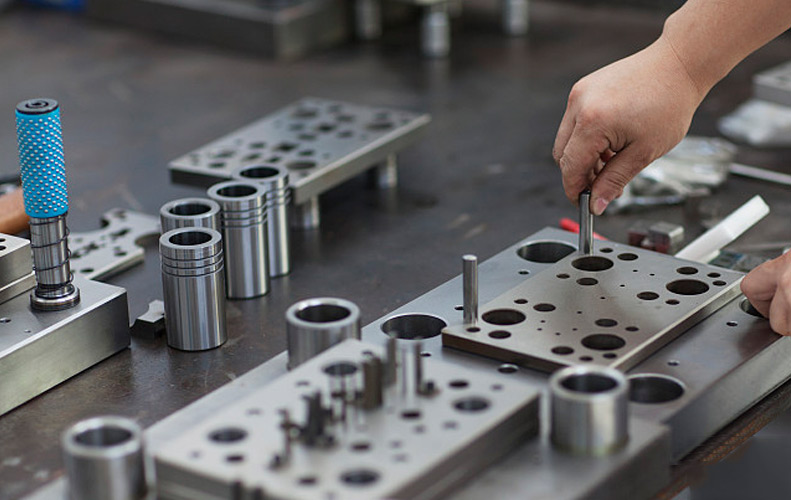

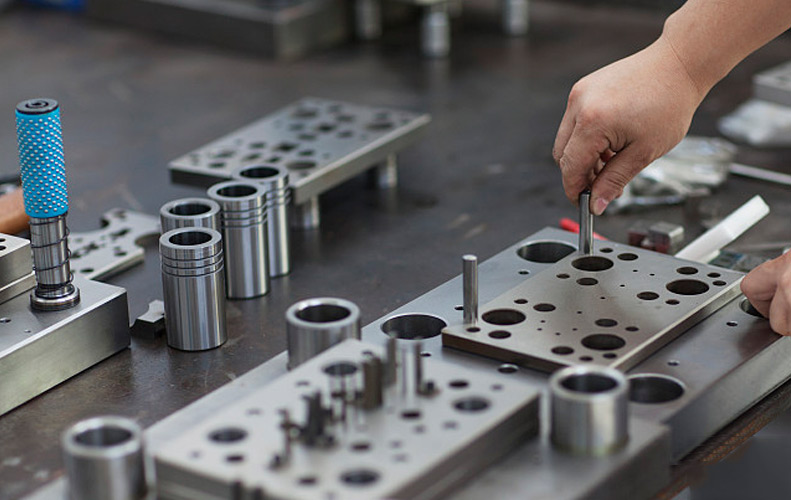

Orienson's Edge Rolling Parts

Edge rolling produced in this way can achieve a thin wall, small weight, but big stiffness and complex shape. The product surface is bright and clean with a good appearance and precise size, and the length can be adjusted as needed. Orienson can produce a variety of products with uniform wall thickness and complex section shapes according to customers' needs. Welcome customers from all walks of life to contact us.

Edge Rolling Parts Design

For thin soft materials (t<=0.5)

A: When the inner diameter of the enclosed circle ∅d<=4.0, the 4-step pressure arc forming method is generally used for the enclosed circle, as shown in Figure 44-1.

B: When the inner diameter of the inner circle is 4. 0<∅d<=15.0, you can use either the 4-step arc forming style for wrapping or the mandrel forming style for wrapping

C: When the inner diameter of the inner circle ∅d>15.0, the mandrel forming method is generally used.

D: If the product requires a high centroid dimension, for the inner diameter of the inner circle ∅ D >3.0, we recommend using the mandrel forming method because it can make the circle a little rounder.

For thick hard materials (t>0.5)

For thick hard materials, if the 4-step pressure arc forming method is used to wrap the circle, it is generally difficult to wrap it around as the centrality is poor.

Because the material's yield strength is high, it is difficult to turn over to roll the material; And thin soft material's yield strength is low, the shape is easy to be rolled when making the formation, therefore, for thick hard material forming, we recommend to choose mandrel forming method to wrap. As shown in figure 44-2

What Is The Common Problems And Solutions In The Stamping Process Of Edge Rolling Parts

We often encounter poor roundness, too big a closure gap, and all kinds of technical problems such as surface pits when stamping edge rolling products. With more than 20 years of development, we already have a complete set of high precision equipment, a technical team, and a perfect scientific management system in the stamping industry, which can quickly help solve the problem of stamping precision and production quality for you. Choose Orienson, choose rest assured!

How Do You Roll Metal Edges?

Progressive die can adopt the forming method as shown in the figure below: the first step is 90° enveloping forming.

The Second Step 180° Enveloping Forming, The Third Step 240° Enveloping Forming, The Fourth Step Full Circle Forming.

As one of the most professoinal metal stamping parts suppliers , we provide sheet metal press parts, stamped sheet metal parts, metal stamping parts,

metal stamping, deep drawingand etc. Want to know metal stamping parts costor more, contact us.

在线联系供应商

Other supplier products

| Bending Parts | The bending process is one of the common processing stamping methods, it refers to the forming method that a sheet and coil is bent into various sh... | |

| Stainless Steel Stamping | Stainless steel stampingis the process of stainless steel material processed by using the mold, which makes its deformation or fracture has a certa... | |

| Copper Stamping | Copper stampingis the processing of copper metal materials into custom-shaped hardware through stamping die. Orienson's Copper Stamping Copper is ... | |

| Steel Stamping | Steel stampingmaterials are mainly hot rolling and cold rolling steel plates and steel bands. Orienson's Steel Stamping Steel stamping material... | |

| Automotive Metal Stamping | Orienson has expanded into the automotive components market for years and produces the highest quality components for the world's top automotive br... |

Same products

| MONSA® CMEA | 卖方: Guangzhou Monsa Chemical Co., Ltd | INCI name: Cocamide MEA Cocamide MEA, or CMEA for short, is a non-ionic surfactant commonly so... | |

| 共轨喷油器 | 卖方: 德艾普(厦门)进出口有限公司 | 商品名称:柴油喷油器型号: 最小起订量:1 件 材质:钢 包装详情:纸箱包装 库存:有库存 品牌:CNDIP 质保:6个月 | |

| 共轨喷油器 | 卖方: 德艾普(厦门)进出口有限公司 | 商品名称:柴油喷油器型号: 最小起订量:1 件 材质:钢 包装详情:纸箱包装 库存:有库存 品牌:CNDIP 质保:6个月 | |

| 共轨喷油器 | 卖方: 德艾普(厦门)进出口有限公司 | 商品名称:柴油喷油器型号: 最小起订量:1 件 材质:钢 包装详情:纸箱包装 库存:有库存 品牌:CNDIP 质保:6个月 | |

| 帕劳灌装液氮罐KGSQ液氮瓶 | 卖方: 河南天之道生物科技有限公司 | 在生命科学研究中,液氮是较为常用的冷冻介质,储存它的容器则成了重要实验工具。实验进行中,为了样本的低温储存环境稳定,需要定期补液以保证充足供应,因为液氮易挥发,液氮量随时间推推移而减少。因此,为... |