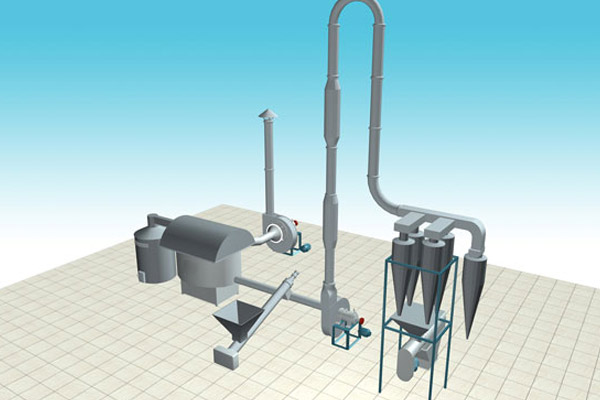

Airflow Flash Dryer(Cassava Drying Machine)

Features of Airflow Flash Dryer(Cassava Drying Machine)

The starch factory at present normally adopt airflow drying (also called flash drying), the whole process time is completed in an instant, so the internal moisture of the starch granules have been dry before gelatinization, the pasting or degradation phenomenon will not occur. Airflow drying is concurrent flow drying process, namely, the concurrent flow of wet powder material and the heat flow, consists of heat transfer and mass transfer process. When wet starch with the hot air in contact, hot air transfer heat to the surface of the wet starch, again from surface to interior, the process is the heat transfer process; At the same time, the moisture in wet starch diffusion from the material inside to the surface of starch by liquid or gaseous, and the diffusion into the hot air from the starch surface through the gas film, it is a mass transfer process. By the high-temperature air and wet starch balanced heat exchanging in the drying tube, the drying starch become dry powder, and then packing and warehousing after cooling.

Processing Capacity: 100-2000Kgs/hour

Application Scope: Cassava starch and flour drying

Product Introduction: Airflow flash dryer, cassava flash dryer, cassava flour drying machine for cassava starch and flour processing

Product Application of Airflow Flash Dryer

Widely used for the drying in starch, modified starch, medicine, food, chemical industry etc particle materials.

Technical Parameters of Airflow Flash Dryer

|

Modelnumber |

Outputyield |

Power |

Voltage |

Finalwatercontent |

Material |

Coverarea |

|

GD-HG-300 |

300kg/hour |

13kw |

380V/50Hz |

≤13% |

Stainlesssteel |

30-40m2 |

|

GD-HG-500 |

500kg/hour |

22kw |

380V/50Hz |

≤13% |

Stainlesssteel |

30-40m2 |

|

GD-HG-1000 |

1000kg/hour |

30kw |

380V/50Hz |

≤13% |

Stainlesssteel |

40-50m2 |

|

GD-HG-2000 |

2tons/hour |

60kw |

380V/50Hz |

≤13% |

Stainlesssteel |

70-80m2 |

在线联系供应商

Other supplier products

| Garri Fryer(Cassava Garri Fryer) 2019 | Features of Garri Fryer(Cassava Garri Fryer) Roasting be done mechanically using an automated garri fryer made of stainless steel material and with... | |

| Potato Washing Machine | cassava flour milling machinecassava machinecassava processing machine Features of Potato Washing Equipment Processing Capacity: 3-20Tons/hourAppl... | |

| Rotary Vacuum Filter | Features of Rotary Vacuum Filter Processing Capacity: 0.2-0.3Tons/h/m2 Application Scope: Cassava or potato starch dewatering Product Introduction:... | |

| Cassava Starch Extraction Machine | Features of Cassava Starch Extraction Machine Processing Capacity: 15-35Tons/hourApplication Scope: Crushing the cassava into the slurryProduct In... | |

| Cassava Grinding Machine | Features of Cassava Grinding Machine Processing Capacity: 3-6Tons/hour Application Scope: Grating the cassava into the slurry. Product Introduction... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |