Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near-surface of the test piece. People can detect defects by detecting the change of leakage magnetic field with MFL testing equipment.

Briefly describe the magnetization of ferromagnetic components. In the magnetic non-destructive testing, magnetization is the first step to realize the detection, which determines whether the leakage magnetic field signal can be generated, and also affects the performance characteristics of the detection signal and the structural characteristics of the detection device. Like magnetic particle inspection, magnetization is achieved by a magnetizer, including both a magnetic source and a magnetic circuit.

The magnetic source and the magnetic circuit change depending on the structure of the member to be tested.

What kind of magnetization can be divided into several categories? The magnetization methods can be generally divided into five categories, namely, alternating current magnetization mode, direct current magnetization mode, permanent magnet magnetization mode, composite magnetization mode, and integrated magnetization method.

What are the characteristics of magnetic flux leakage detection technology?

Because leakage magnetic field detection uses magnetic sensors to detect defects, compared with magnetic powder, penetration and other methods, it has the following advantages:

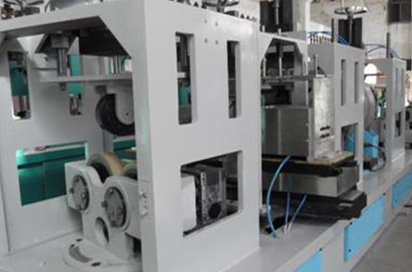

BKN's portable magnetic flux leakage testing equipmentare capable of detecting workpieces efficiently and accurately.

As an mfl testingequipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

We are one of the professional non destructive testing equipment suppliers,we provide magnetic flux leakage equipment,mfl equipment,mfl ndt,magnetic flux detectorand ndt testing,if you don’t know what is flux leakage,we will tell you.

在线联系供应商

Other supplier products

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testing system is a full automatic crack hardness sorter that integrates light, electricity and machinery. The w... | |

| Bolt Vortex Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Wireless Transmission Pipe Ultrasonic Flaw Detector | The ultrasonic pipe testing equipmentsystem is suitable for the automatic detection of various internal and external defects of steel pipes. The pr... | |

| ECT For Automotive And Aerosapce | Eddy current testing technology has been widely used in the detection of metal components in the automotive and aerospace industry. In order to ens... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld inspectionis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |