Wireless Transmission Steel Bar Ultrasonic Flaw Detector

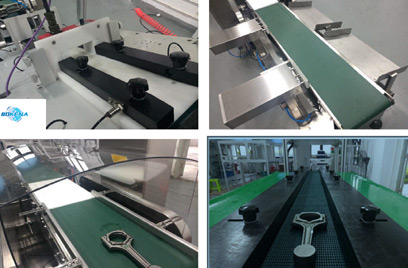

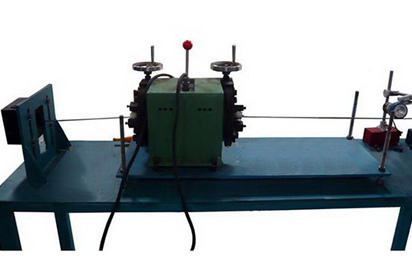

Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external defects of various steel bars.

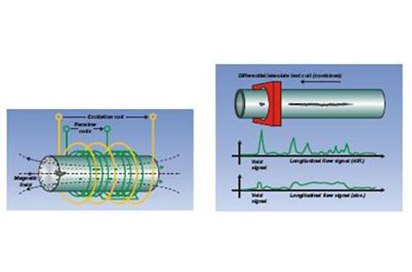

The principle of UT ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel rod by water, the incident propagation will case ultrasonic reflection when there is a defect in the bar. The ultrasonic instrument will alarm the ultrasonic reflected signal after the amplified signal to realize the automatic detection of the defect.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector Brief Introduction

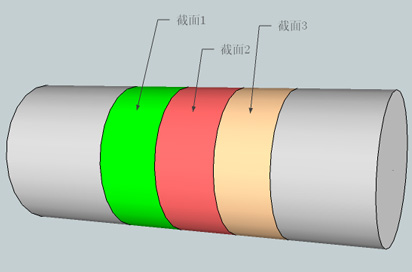

There are two probe regulators in section 1,180 degrees apart. Each regulator is equipped with a two-channel combination of ultrasonic line focus probes, and the transverse wave incident clockwise.

Detection of defects: detection of round subcutaneous defects in a rounded clockwise direction

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each set consisting of 2 combined wafers, which are evenly distributed in the circumferential direction of the workpiece, 180° apart, on the same section. A total of 4 independent channels.

A total of 2 probe adjustment frames are placed on section 2, each separated by 180°, and a 2-channel combined ultrasonic line focusing probe is arranged on each adjustment frame, and the longitudinal wave is incident.

Detection of defects: metallurgical defects inside the steel bar,

Detection range: center transverse hole.

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each consisting of 2 combined wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, 180° apart, and there are 4 independent channels in the same section.

A total of 2 probe adjustment frames are placed on section 3, each separated by 180°, and a 2-channel combined ultrasonic line focusing probe is arranged on each adjustment frame, and the transverse wave is incident counterclockwise.

Detection of defects: counter-clockwise detection of round subcutaneous defects

Center frequency: 5.0MHz ± 10%

Coupling method: water immersion method

Quantity: 2 sets of probes, each consisting of 2 combined wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, 180° apart, and there are 4 independent channels in the same section.

Defect detection standard

GB/T4162-2008 Ultrasonic testing method for forged steel bar.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector Parameters

|

Channel number |

12 channels |

|

Flaw detection speed |

30m/min |

|

Total gain |

100dB,step0.5dB |

|

Working mode |

Single probe transmitting, receiving or double probe transmitting and receiving respectively |

|

Sensitivity margin |

≥50dB |

|

Resolving power |

≥26dB |

|

Dynamic range |

≥30dB |

|

scan range |

0~5000mm |

|

Frequency range |

|

|

Sampling range |

250MHz |

|

Repetition range |

Single channel100Hz~4KHzadjustment |

|

Vertical linearity |

≤2% |

|

Horizontal linearity |

≤1% |

|

Detection mode |

Full-wave, positive half-wave, negative half-wave |

|

Gate setting |

Each channel has three gates, A and B are defective gates and C are interface tracking gates. |

|

Alarm indication |

Color Display and Sound Alarm of A, B and C Gate Alarm on Each Channel |

|

Delayed alarm |

Two path,delay time 0.1-10s,step 0.1s |

|

Waveform storage, unlimited number, waveform playback, printing and report generation. |

|

BKNprovides ndt device,ultrasonic metal testing equipment,ultrasonic bar testingand ultrasonic metal testing,contact us now.

在线联系供应商

Other supplier products

| BKNET-101 Automatic Eddy Current Testing | The eddy current testing (BKNET-101) is a fully automated eddy current inspection systemthat uses large-scale imported integrated circuits combined... | |

| Portable Magnetic Flux Leakage Testing Equipment | MFLequipmentrefers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface... | |

| Eddy Current Testing Equipment | ECT Eddy current testing used by eddy current testing machine is a non-contact testing method, which mainly uses the electromagnetic field and elec... | |

| Eddy Current Testing Equipment | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Using the eddy current signal processing method and high-performance DSP algorithm, the NDT ... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... |

Same products

| JX50D China CNC Machine Tools | 卖方: Taizhou Yestar Intelligent Equipment Co.,Ltd | China CNC Machine Tools List 1. Servo Hydraulic Turret: Compact design with a small footprint, h... | |

| Sewing Machine Spare Parts | 卖方: Jinzen Intelligent Technology (Dongyang) Co., Ltd. | Sewing Machine Spare Parts B2001-771-0A0 LBH-780 One of the key features of our spare parts is t... | |

| 钢轨磨耗测量尺 | 卖方: 842518 | LJ-GM系列数显式钢轨磨耗测量尺用于测量钢轨垂直磨耗和侧面磨耗量。釆用数显读数,合理的设计使它具有重量轻、操作方便、读数直观的特点。 | |

| 道岔尖轨侧磨量及降低值检测尺 | 卖方: 842518 | 尖轨是转辙器中的重要部件,依靠尖轨的扳动,将列车引入正线或侧线方向。随着铁路运输不断向高速化和重载化方向发展,加速了道岔尖轨的磨损和报废,特别是尖轨的侧磨较为严重,要经常测量尖轨的磨耗状态,给出... | |

| 滑动式钢轨磨耗尺 | 卖方: 842518 | LJ-HGM系列滑动式钢轨磨耗测量尺用于测量钢轨垂直磨耗值,侧面磨耗值和尖轨降低值。釆用数显读数,合理的设计使它具有重量轻、操作方便、读数直观的特点。 |