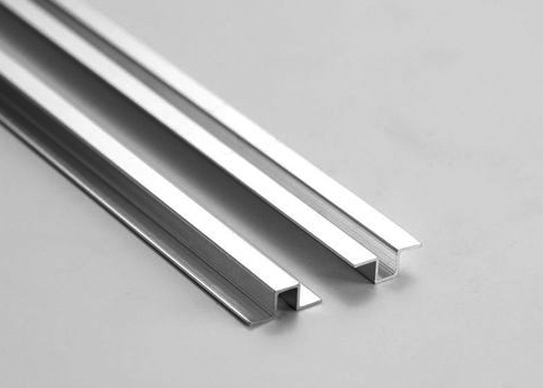

METAL FLANGING

Flanging refers to the stamping process of turning the edge or outer edge of the hole on the workpiece into an upright straight edge with a die. It is included in the forming process of stamping.

WHAT IS THE ADVANTAGE OF METAL FLANGING?

It can process precision stamping parts with complex shape and good rigidity.

Improve the production efficiency. Save dies for some deep drawing parts. Reduce the manufacturing cost.

It can replace the deep drawing work of a complex shape workpiece, so flanging is especially suitable for small batch trial production.

Flanging is usually applied at the edge of the stamping part, which can effectively save the material.

WHAT SHOULD BE CONCERNED IN METAL FLAGGING?

Flanging is a stamping method that turns the workpiece with holes punched in advance into vertical flange along the hole edge. The deformation of hole flanging is from the tensile deformation of the material along the tangential direction, and the closer to the edges, the greater the deformation and the flanged area of workpiece gets thinner. Due to that, the hole edge may be cracked if not dealt properly. In order to prevent the cracking, the flanging degree of the inner hole of the workpiece must not be too large. If the flanging height is large, we can process flanging several times instead.

In flanging, the deformation degree is expressed by cofficient "K", which is the ratio of the aperture before flanging to the aperture after flanging. Obviously, the larger the value of K, the smaller the degree of deformation. On contrary, the smaller the value of K, the greater the degree of deformation, and more likely the edge of the flanging hole will be broken. The minimum value of K occurs with the maximum deformation degree which can be achieved without cracking the hole edge.

In order to prevent edge cracking, K shall not be too small and shall be greater than the minimum value introduced above. Experience shows that the minimum value of K is not only related to the type and performance of the material, but also to the relative thickness of the blank, and the shape of the product.

If you need any kinds of metal work fabrication, please contact us, as a professional metalworking factory, Hongkun is willing to offer you high quality products.

在线联系供应商

Other supplier products

| CAR EXHAUST PIPE | Car exhaust pipeis installed between the engine exhaust branch pipe and the muffler, making the whole exhaust system flexible. In this way, it c... | |

| CAR GLASS LIFTER | The commonly used car glass lifteris composed of motor, reducer, guide rope, guide plate, glass mounting bracket, etc. It is a lifting device for a... | |

| CAR GLASS LIFTER | The commonly used car glass lifteris composed of motor, reducer, guide rope, guide plate, glass mounting bracket, etc. It is a lifting device for a... | |

| METAL FLANGING | Flanging refers to the stamping process of turning the edge or outer edge of the hole on the workpiece into an upright straight edge with a die. It... | |

| CAR SEAT BRACKET | The main function of custom car seat bracketsis to keep the driver in a correct sitting position, provide support for the upper body when turning, ... |

Same products

| BLIIOT BL360 Industrial ARM Computers Powered By NXP Mx8m Mini with Quad Core Cortex A53 M4 | 卖方: 深圳市钡铼技术有限公司 | BL360 Industrial ARM Computers built on NXP i.MX8M Mini with quad-core Cortex-A53+M4. As a Indust... | |

| BLIIOT ARMxy BL350 Industrial Embedded Computer With Ti Sitara Am62x Processor | 卖方: 深圳市钡铼技术有限公司 | BL350 is an Industrial Embedded Controller powered by the TI Sitara AM62x processor with up to qu... | |

| BLIIOT BL460 Powered by Raspberry Pi CM5 Industrial Embedded Computer | 卖方: 深圳市钡铼技术有限公司 | Industrial AI Embedded Computer BL460 based on the Raspberry Pi CM5 module and compatible with th... | |

| 30-160KW 10-30Khz Induction Heating Machine | 卖方: Chengdu Duolin Electric Co.,Ltd | 30-160KW 10-30Khz Induction Heating Machine Ultrasonic induction heating equipment IGBT inverte... | |

| Vertical Bendable Neon Flex LED Strips 15X16mm | 卖方: Shenzhen Blue Diamond Technology Co.,Ltd | Vertical Bendable Neon Flex LED Strips 15X16mm This Vertical Bendable Neon Flex LED Strips are v... |