UHMWPE Molded Sheet

UHMWPE Molded Sheet

Molded UHMWPEsheets find extensive use in a wide range of industries, including automotive, food processing, packaging, marine, construction, and transportation. They are commonly utilized for applications such as wear strips, guide rails, liners, slide plates, bumpers, and various structural components.

Mechanical Properties of UHMWPE Molded Sheet

|

Indications name |

Unit |

Test method |

Indicators |

|

Density |

g/cm³ |

ASTM1505 |

|

|

Fracture strength |

Mpa |

D638 |

42 |

|

Elongation at break |

% |

D638 |

350 |

|

Impact strength |

Kj/m² |

D256 |

≥100 |

Types and Specifications of UHMWPE Molded Sheet

Boards: have molded plate and extrusion plate two class.

|

The name of the project |

Unit |

The shape size (length*width*thickness) |

Remarks |

|

|

Moulded board |

mm |

4200*1035 (6-200) |

||

|

mm |

4200*1250 (6-180) |

|||

|

mm |

3150*2040 (6-150) |

|||

|

Extrusion board |

mm |

Width 113*thickness 3*unlimited length |

||

|

mm |

Width1030*thickness 6*unlimited length |

|||

Features of UHMWPE Molded Sheet

UHMWPE plasticis a thermoplastic engineering plastic, which integrates the superior properties of all plastics. The five characteristics of impact resistance, wear resistance, chemical corrosion resistance, self-lubrication and impact absorption performance are the highest values of all existing plastics at present.

Cold tolerance:

UHMWPE can even act in liquid nitrogen or liquid nitrogen, its use temperature can reach below -269 ℃, still has a certain mechanical strength.

Wear resistance:

UHMWPE has excellent wear resistance, the higher the molecular weight, the better the wear resistance of the material.

Bibulous rate:

UHMWPE has very low water absorption.

Excellent resistance to chemical corrosion properties:

UHMWPE chemical stability is very high, in a certain temperature, concentration range can resist acid, alkali, salt and other corrosive media.

UHMWPE tasteless, non-toxic, odorless, no corrosive in itself. The US food and drug administration(FDA) and the United States department of agriculture (USDA) allows it for special occasions in contact with the food and drug. Therefore, UHMWPE is suitable for food, medicine and other industies with higher requirements for hygiene conditions.

If you want to know more kinds of uhmw polyethylene tube, please visit our website.

在线联系供应商

Other supplier products

| PTFE Corrugated Tube | The process is to make corrugated PTFEtubeat a certain speed through a temperature of 270℃ ~ 280℃ continuous forward rotation mold. It has all the ... | |

| PTFE Products | As one of the professional PTFE products manufacturers, Jiangsu Xinrui Plastic Technology specializes in manufacturing polytetrafluoroethylene prod... | |

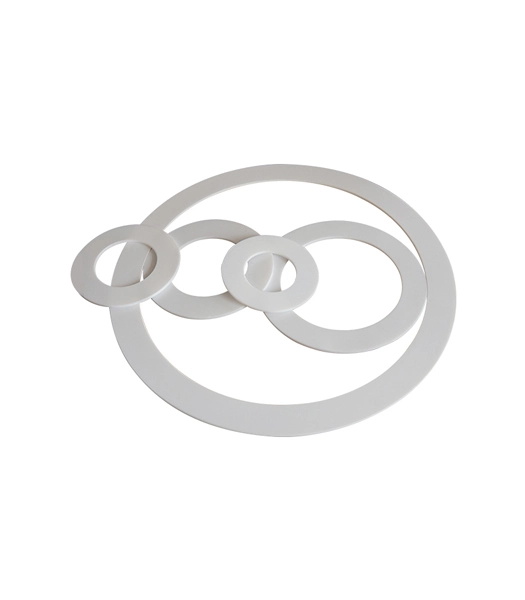

| PTFE Ring | PTFE RingPTFE sealing products not only can seal oil fluid, can also seal water a class of fluids, including strong acid, strong alkali, strong c... | |

| PTFE Gasket | PTFE Gasket A pure ptfe gasketis a type of sealing component made from PTFE material, which is a synthetic fluoropolymer known for its excellent... | |

| Self Adhesive PTFE Sheet | Self Adhesive PTFE Sheet PTFE surface itself is not adhesive, such as want to bond and other substances must need one side and two sides after Nan... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |