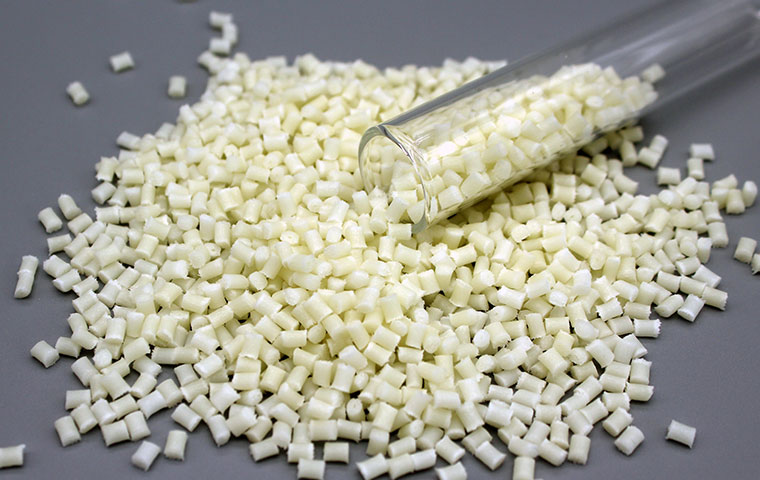

Nylon66 pa66

Nylon 66 is polyamide 66. The main purpose of Nylon 66 plastic modification is to improve the properties of Nylon 66 material based on the original resin properties to meet specific requirements. The chemical and physical properties of Nylon 66 PA 66 are very similar to Nylon 6, so the modification method is similar. Anmeimodified Nylon 66 series includes flame retardant, reinforced, toughened and other modified products.

Nylon 66 pa66plastic modified with the toughening agent has greatly improved Izod impact strength.

··

Filling modified polyamide 66 can not only reduce molding shrinkage but also improve heat resistance and dimensional stability. The most important is to reduce material costs.

··

Carbon black can improve the weather resistance of polyamide 66.

As one of the mature nylon 66 suppliersand pa66 manufacturers, Anmei provides nylon 66 material at a very competitive polyamide 66 price. Please contact our engineers to develop the best solution for your nylon 66 products.

Nylon 66 Products

Nylon 66 plastic is a kind of engineering thermoplastics that can be easily colored and processed. Nylon 66 (PA66) has a higher melting point and slightly higher mechanical properties than nylon 6. Different forms such as Nylon66 PA66 with high tensile strength, Nylon66 PA66 Heat Stabilized, Nylon66 PA66 FR are available in Anmei. Nylon 66 plastic material is known to have excellent chemical resistance. In addition, the polyamide 66 has good mechanical and thermal properties.

Nylon PA66 Material Properties

Advantages of PA66 Material:

▲High strength, rigidity and toughness in a wide temperature range

▲Excellent wear resistance and self-lubricating properties

▲Excellent resistance to gasoline and lubricating oil such as hydrocarbons, gasoline, oil, weak acid and alkali

▲Good electrical insulation

Limitations of PA66 Material:

▲High water absorption

Easy to lead to the decline of electrical insulation, it must be dried before processing

▲Poor thermal stability

The long-term processing at high temperatures should be avoided

Nylon 66 Manufacturing Process & Temperature

Prior to blending, nylon pa6 6 was dried at 130°C for 3 h to remove most of the absorbed humidity. The composites were prepared by a Coperion twin-screw extruder. The temperature profiles of the barrel were 240-270°C for both the cylinder and the nozzle. The extrudate in the form of a cylindrical rod was subsequently cooled down in the water and then pelletized. The first part of the extrudate was discarded because impurities should be flushed out of the system to ensure product quality of nylon 6.6. The following steps of nylon 66 plastic manufacturing process are sample testing, weighing, labeling and packaging.

Q:

What Is PA66 Material?

PA 6.6 material is a translucent or opaque milky white crystalline resin, which is the earliest developed polyamide variety. Nylon 66 PA66 can maintain strong strength and rigidity at higher temperatures and is insoluble in general solvents such as gasoline and lubricating oil.

Nylon 66 PA66 plastic is hygroscopic, the extent of which depends primarily on the composition of the material, wall thickness and environmental conditions. When designing a product, it is important to consider the effect of hygroscopicity on geometric stability. In order to improve the mechanical properties of Nylon 66 PA66, various modifiers are often added, and glass fiber is the most common additive.

Q:

Is Nylon 66 Biodegradable?

Biodegradation refers to the degradation by the action of microorganisms existing in nature such as bacteria, molds, and algae. The ideal biodegradation is one with excellent performance, which can be decomposed by environmental microorganisms after being discarded, and become an integral part of the carbon cycle in nature by being mineralized. Nylon66 PA66 is a non-biodegradable plastic. Currently, polyamide 66 is mainly recycled by waste processing plants. It is subdivided, crushed and granulated to achieve recycling.

Q:

What Is The Raw Material For Nylon 66?

Nylon 66, also known as polyhexamethylene adipamide, is a thermoplastic resin, which is generally obtained by polycondensation of nylon-66 salt with adipic acid and hexamethylenediamine. Nylon 66 is insoluble in common solvents, it is only soluble in m-cresol. It has high mechanical strength and hardness and high rigidity, and can be used as engineering plastics, such as gears and lubricating bearings of mechanical accessories, replacing non-ferrous metal materials for machine casings and automobile engines blades.

If you are looking for a reliable engineering plastic company, don't hesitate to contact us!

在线联系供应商

Other supplier products

| PA6 GF45 (A1011I) for Engineering Plastics | Polyamide 6 reinforced with 45% Glass Fibers that is PA6 GF45, medium viscosity and dimensional stability, the PA GF45has excellent rigidity and hi... | |

| PA66 GF35 (A2000G, A2011G, A2111G) | PA66 is nylon 66, namely polyamide 66. GF is glass fiber. Generally expressed as pa 6.6 gf 35, that is, 35% glass fiber is added to nylon 66. Typi... | |

| Color Masterbatch | As one ofmasterbatch suppliers, Anmei serves customers with tailored-making solutions from standard colors to customized colors and functions. Ther... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF30is a common nylon material known for its high str... | |

| Ultrasonic Surgical System | Anmei, one of the professional plastic master batch manufacturers, has a range of customized masterbatches available which incorporate Anti-mold Ma... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |