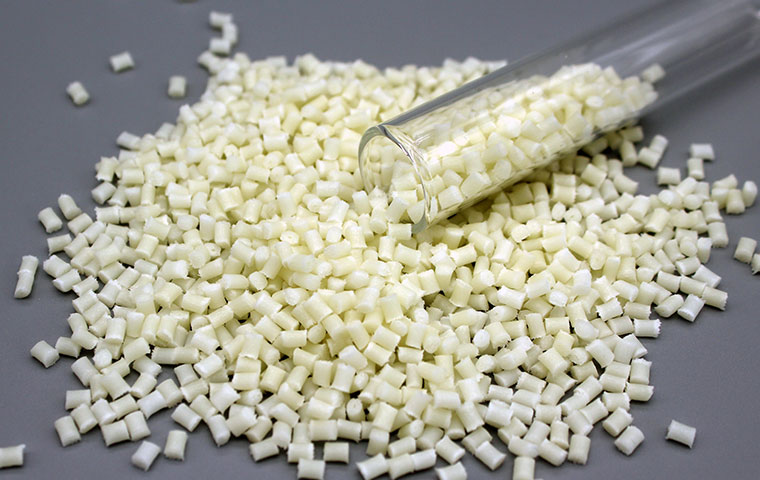

PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics

Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF30is a common nylon material known for its high strength and durability, as well as provides enhanced mechanical properties. The glass fiber reinforcement of PA66 30GFplastic improves the material's stiffness, dimensional stability, and resistance to heat, making it suitable for a wide range of applications that require strength and rigidity.

Advantages of Anmei PA66 GF30 Heat Stabilized (A2006F)

Anmei is a highly regarded company in China, known for its expertise as one of the most professional suppliers and manufacturers of pa66 gf30 plastic(polyamide 6,6 with 30% glass fiber) materials. With a strong focus on quality and customer satisfaction, Anmei has established itself as a reliable source for high-quality PA6 6 GF30 products.

As a leading supplier, Anmei offers a diverse range of pa66 gf30 materialthat meet the exacting requirements of various industries. Their manufacturing capabilities, supported by advanced technology and stringent quality control processes, ensure consistent and superior product performance.

As a professional PA66 GF30 manufacturer, Anmei's commitment to customer-centricity is evident in our approach, as we work closely with clients to understand their specific needs and provide tailored solutions. Our knowledgeable team of professionals possesses in-depth expertise in material PA66 GF30 and its applications, offering valuable technical support and guidance throughout the procurement process.

When it comes to sustainability, Anmei groupsets a high standard. We prioritize environmentally friendly manufacturing practices and adhere to strict environmental regulations. By responsibly managing resources and adopting sustainable practices, Anmei offers eco-conscious solutions to clients seeking environmentally responsible materials.

Typical Application of PA66 GF30 Heat Stabilized (A2006F)

PA66 GF30 Heat Stabilized (A2006F) is a type of plastic material that is reinforced with 30% glass fiber. It offers a combination of properties that make it suitable for a wide range of applications. The material PA66 GF30 thermal stability typically works for automobile engines, motor accessories such as engine covers, cooling fans, coil frames, and plugs, sockets and spools in electrical and electronic fields. Here are some typical applications of PA66 GF30 Heat Stabilized (A2006F), considering the keywords you provided:

Automotive Components

PA66 30 GF Heat Stabilized (A2006F) is commonly used in the automotive industry for manufacturing various components. Its high strength, rigidity, and heat resistance make it ideal for applications such as intake manifolds, engine covers, radiator tanks, fuel system components, and structural parts.

Electrical and Electronic Applications

PA6 6 GF 30 is well-suited for electrical and electronic applications that require good electrical insulation and mechanical strength. It can be used to produce components like electrical connectors, switches, circuit breakers, and other parts used in electrical systems.

Industrial Equipment

With its excellent mechanical properties and resistance to heat and chemicals, PA66 GF30 material finds applications in various industrial equipment. It is commonly used for manufacturing gears, bearings, rollers, pump components, and housings.

Consumer Goods

GF30 material PA6 6 is utilized in the production of durable consumer goods. Its high strength and rigidity make it suitable for manufacturing power tools, sports equipment, furniture components, and other products that require mechanical strength and heat resistance.

Appliances

In the appliance industry, PA66 GF30 Plastic is commonly applied to producing components that require heat resistance and mechanical strength. It finds applications in parts such as washing machine components, vacuum cleaner housings, oven components, and other heat-resistant parts.

Processing Detail of PA66 GF30 Heat Stabilized (A2006F)

PA66 GF30 Properties (Heat Stabilized A2006F)

|

Physical Property |

|

|

Ash |

(30.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1365Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.2-0.5 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.6-0.9% I ISO294-4) |

|

Mechanical Properties |

|

|

Tensile strength (105.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.6% I ISO527) Conditioned |

5mm/ min |

|

Notched Impact Strength (10.0 KJ/m2 I ISO179) Conditioned |

|

|

Flexural Strength (177MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (5050 MPa I ISO178) Conditioned |

2mm/min |

|

Thermal Property |

|

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(250*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

mm |

|

Injection Molding Conditions |

|

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

280-300°C |

|

Nozzle Temperature |

280-300*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions are just for reference, please make an adjustment based on the actual situation!

PA66 GF30 Heat Stabilized FAQs

Can PA66 GF30 Heat Stabilized Be Recycled?

Yes, PA66 GF30 Heat Stabilized can be recycled. However, the presence of glass fibers can complicate the recycling process. Specialized recycling methods may be required to separate the glass fibers from the polymer matrix.

What Are the Temperature Limits for PA66 GF30?

PA66 GF30 typically has a high heat resistance, with temperature limits ranging from around 120°C to 200°C (248°F to 392°F), depending on the specific formulation and application requirements. It retains its mechanical properties at elevated temperatures.

Are There Any Limitations to Using PA66 GF30?

PA66 GF30 may have higher material costs compared to unfilled polymers. It can also be more difficult to process due to the presence of glass fibers. Design considerations should be taken into account to avoid issues such as warpage and mold filling.

If you want to know more about density pa66 gf30, please contact us.

As a reliable engineered plastics company, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| PA6 GF20 Heat Stabilized (A1006D, A1016D) for Engineering Plastics | PA6 GF 20has 20% glass fiber filler. It has much greater heat-resistant mechanical properties than unfilled polyamide. Anmeiplastics has always bee... | |

| TPU Slip Masterbatch & Frosted Matte Masterbatch for Engineering Plastics | Anmei company specializes in the production of TPU slip masterbatchingredients and TPU frosted matte masterbatch excellent dispersibility in cast f... | |

| PA6 GF in Anmei | As an engineered plastics company, Anmei focuses on the production of modified engineering plastics, among which high-performance nylon 6 engineeri... | |

| PA6 GF30 Halogenated FR (A1014F) for Engineering Plastics | PA6 GF30 FRis a PA6 with 30% glass-fibers and halogens flame retardant. PA 6 GF30Halogenated FR Features Glass fiber reinforced 30% ... | |

| Antimicrobial Masterbatch | Antibacterial Masterbatchfor Engineering Plastics Polymer anti-bacterial masterbatch is a kind ofmasterbatch materialthat adds antibacterial agent... |

Same products

| Defoamer Powder | 卖方: Shandong Jufu Chemical Technology Co., Ltd. | Antifoaming agent powder primarily serves as an essential component in cement and concrete produc... | |

| PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% ... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF3... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This t... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Applic... |