Footwear Cold Insulation Tester

Product Introduction:

Shoes cold resistance testing machine is used to test finished shoes, rubber, sole, synthetic leather, plastic and other test requirements under various low temperature environment to understand the ability of various materials or finished shoes to adapt to low temperature climate or cold terrain area, this instrument is made of rust SUS steel, can be installed with a variety of different test fixtures. In order to meet the different standards of various tests.

Meet the standard:

ASTM D17900. EN ISO 20344. HG/T 2411. HG/T 2871. DIN 53351. SATR TM55. Adidas GE-24. GE-57. GB/T 20991-2007 and other standards

Product Advantages:

Controlled Low-Temperature Environment: Provides a stable and precise cold environment for conditioning and testing.

Versatile Material Testing: Suitable for testing a wide range of footwear materials and finished shoes.

Standard Compliant: Designed to meet numerous national, international, and industry-specific standards for cold resistance testing.

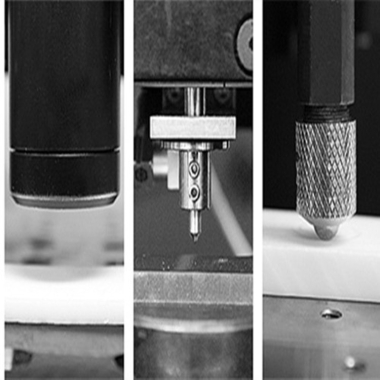

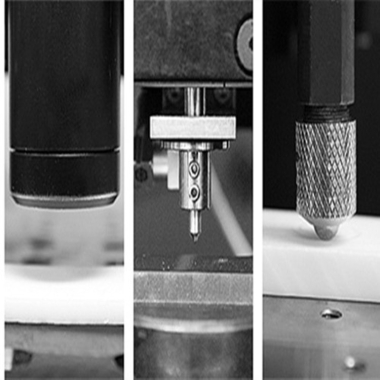

Accommodates Various Tests: Can be equipped with different fixtures to perform various low-temperature tests (e.g., cold flex, cold impact, thermal insulation).

Wide Temperature Range: Capable of reaching very low temperatures, covering a broad range of cold climate conditions.

Accurate Temperature Control: Features balanced temperature control with high accuracy, uniformity, and minimal fluctuation.

Durable Construction: Made from rust-resistant stainless steel.

Includes Thermal Test Fixture: Equipped with components for conducting low-temperature thermal tests.

Main parameters of cold box:

1. balanced temperature regulator humidity control system

2. temperature range: -25℃ —— +150℃

3. temperature fluctuation: ≤±0.5℃

4. temperature uniformity: ≤2℃

5. temperature accuracy: ±0.2℃

6. heating time: +25℃→+85℃ room temperature to 85℃ about 30 minutes no load

7. cooling time: +25℃→-40℃ room temperature to -40℃ about 50 minutes no load

8. Lead hole: φ50mm 1 (with 1 rubber plug)

9. heating rate: 3 —— 5℃/min(average), cooling rate: 0.7 —— 1℃/min(average)

Shoe thermal test fixture set:

A: Cold medium: composed of 5mm diameter and 4kg total mass of stainless steel balls

B: Test copper plate: (350±5)*(150±1)*(5±0.1)mm

C: thermometer: accuracy is ±0.5 ° C

The fixture group should be configured according to actual test requirements or other standard requirements.

在线联系供应商

Other supplier products

| Standard Helmet Visual Field Tester/ Helmet Vision Tester / helmet vision testing equipment | Standard EN 1078:2023: Helmets for Pedal Cyclists, Skateboarders, and Roller Skaters CE Certification(Conformité Européenne) Equ... | |

| Circular Locus Pilling Tester | Testing Standards: GB/T 4802.1. JIG 040-1990 Product Information: The Circular Locus Pilling Tester is used for determining the pilling and fu... | |

| KES - FB3 - A Compression Tester | Content TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by artisans and professionals when judging a... | |

| Pipe coating scratch tester | Product Introduction: Paint and varnish scratch resistance tester, also known as scratch resistance tester or balanced scratch rod adhesion resist... | |

| Respiratory Resistance Tester | Respiratory Resistance Tester Introduction: The respiratory resistance tester is used to determine the inspiratory and expiratory resistance of re... |

Same products

| Scott Flex Tester | 卖方: 标准集团 | Product Introduction: Scott kneading tester is suitable for back and forth kneading resistance o... | |

| NEU nanofiber electrospinning device | 卖方: 标准集团 | Content The Nanofiber Electrospinning Unit uses electrospinning techniques to safely and easil... | |

| KK03 Scratch tester | 卖方: 标准集团 | Product Introduction: With the continuous expansion of the use of plastic molding products, from... | |

| KK02 Scratch tester | 卖方: 标准集团 | Product Introduction: With the continuous expansion of the use of plastic molding products, from... | |

| KK01 Scratch tester | 卖方: 标准集团 | Product Introduction: With the continuous expansion of the use of plastic molding products, from... |