Fabric liquid penetration tester

Main Parameters

1. The penetrating disc is made of special organic glass through special processing, ensuring a weight of 500 grams ± 5 grams.

2. Large-capacity burette, greater than 100 ml.

3. Moving stroke of the burette: 0.1 - 150 mm.

4. Moving speed of the burette: approximately 50 - 200 mm/min.

5. Liquid flow rate: controlled to pass through 80 ml within 6 seconds, with an error less than 2 ml.

Main Features

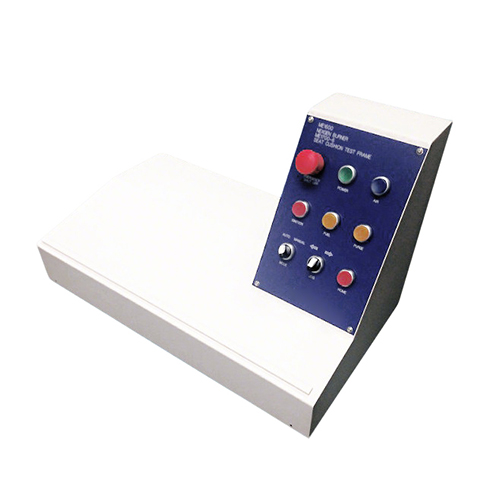

1. The whole machine is processed with high-quality metal spray paint.

2. The specimen platform is made of imported special aluminum profiles, featuring light weight, smooth surface, and rust resistance.

3. Made of imported special aluminum brushed panel with metal buttons.

4. Equipped with an imported meter head.

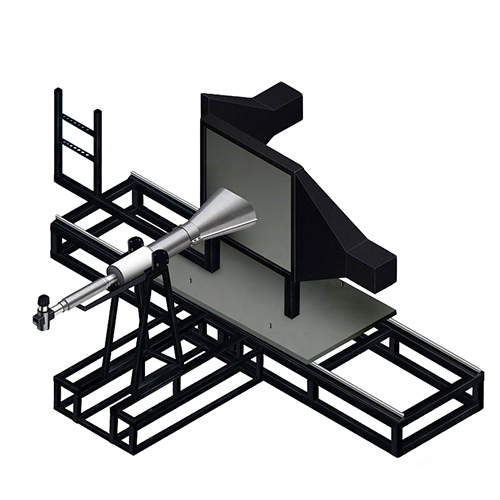

5. The penetrating disc is equipped with a precision positioning device.

6. The specimen clamping can directly lift the penetrating disc and is equipped with positioning and fixing devices.

7. The electrode of the penetrating disc is made of special platinum wire material.

8. The penetrating disc is equipped with a quick connection interface, which can conveniently replace additional penetrating discs.

9. The liquid release is equipped with an automatic release device, enabling automatic control.

Test Procedure

1. Place the liquid penetration tester on a stable test bench and adjust the instrument to be level, making the whole instrument as horizontal as possible. Connect the power cord at the back of the box to the power socket and connect the grounding wire to the grounding terminal on the back of the box. Connect the plug of the penetrating disc electrode to signal connector 1 on the instrument control box and the plug of the solenoid valve to signal connector 2. After preparing the instrument, turn on the power switch on the instrument panel.

2. Prepare the consumables for the test, such as experimental liquid (simulated urine), test samples, absorbent paper for testing, etc.

3. **Step 1**: Cut a specimen of 125 mm × 125 mm and condition it according to the standard requirements. Place the standard absorbent pad and the specimen from bottom to top in the specimen positioning disc (the side of the specimen that contacts the skin facing up).

4. **Step 2**: Loosen the funnel positioning screw, adjust the height of the funnel so that the distance between the nozzle of the funnel and the top surface of the specimen is 30 mm, and then tighten the positioning screw.

5. **Step 3**: Place the penetrating disc on the specimen (ensure that the penetrating disc is clean to avoid affecting the test results), and make sure that the center of each disc is concentric with the center of the funnel during the placement process.

6. **Step 4**: Use a syringe to draw 5 ml of liquid and drop it into the funnel. Press the start switch button on the panel, and the solenoid valve of the funnel opens, allowing the liquid to flow into the circular cavity of the penetrating disc.

7. **Step 5**: After the liquid flows into the circular cavity of the penetrating disc, connect the electrode. The timer automatically starts timing. When all the liquid seeps into the standard absorbent pad and the liquid level drops below the electrode, the two electrodes are disconnected, and the timer stops timing. Read the time recorded by the timer, which is the penetration time.

8. **Step 6**: Replace the standard absorbent pad and the specimen, and repeat steps 4 - 10 of the determination of the liquid penetration time until all specimens are tested.

9. **Step 7**: After the determination of the liquid penetration time (simulated urine) for the entire test is completed, promptly clean up the liquid in the positioning disc and turn off the power.

10. After the experiment, be sure to clean the instrument and carefully wash the experimental funnel, pipeline, load platform and other key components with clean water to ensure the accuracy of the instrument.

在线联系供应商

Other supplier products

| Car seat component clearance test bench Degree of automation: | Applicable standards: Car seat component clearance test benches usually follow the following domestic and international standards: QC/T 805-2008"... | |

| (Ford) Automotive wire flexibility testing machine | Applicable standards: Engineering Specification-Ford Global Wire specificationPART NO. ES-AU5T-1A348-AA Scope of application: Suitable for wir... | |

| Suga GX25 | GX25 is designed to artificially reproduce indoor deterioration factors such as sunlight,temperature and humidity.GX25 exposes materials to these... | |

| Textile moisture absorption and heat generation performance tester | Application ScopeThe textile moisture absorption and heat generation performance tester is a dedicated instrument for testing the moisture absorpti... | |

| Fiber Thermal Shrinkage Tester | Thefiber thermal shrinkage testeris lately developed based on the digital technology. It is applied to the dry thermal shrinkage test of staple c... |