UV-master

In response to the climate resistance testing requirements for outdoor textiles, this equipment can simulate outdoor climate conditions and accelerate testing. Textiles may undergo yellowing, decline, and structural changes under the stimulation of outdoor ultraviolet radiation.

UV testing is conducted by exposing materials to high temperature control conditions and alternating cycles of ultraviolet light exposure and humidity UV uses fluorescent ultraviolet lamps to simulate sunlight, and simulates dew and rainwater through condensation or water spraying. The aging types of textiles include discoloration, loss of luster, powdering, cracking, foaming, brittleness,decline, oxidation, etc

Standards:

ASTM G151 ASTM D4329 D4329 ASTM-D4587.ASTM-G154

Technical parameters:

1. Blackboard temperature setting range:BPT 40-110 ℃; BST 40-120 ℃, but the actual temperature limit of the temperature protection device inside the machine is93 ℃± 10%.

Blackboard temperature control accuracy:± 2 ℃.Blackboard temperature sensors are consumables that require frequent wiping. The surface paint may peel off after a certain period of time, affecting the control accuracy. Therefore, if there is a significant change in color, it needs to be replaced. The specific time depends on the usage situation, usually around two years.

2. Sample size: 48 standard samples of75 * 150mmcan be placed;

3. Sample thickness: The sample thickness shall not exceed 10mm

4. UV wavelength:UVA-340

5. Simulated condensation: The condensation system time can be adjusted

6. Test time: adjustable from0 to 9999

7. Irradiance: adjustable from0 to 1.6w/m2

8. Test time: It can continuously accumulate test time without resetting due to power outages or other factors

9. Irradiance calibration: The irradiance can be calibrated at any point within the set range without changing the program being executed

10. Calibration process: The calibration process achieves automatic input correction to avoid errors caused by manual input

11. UV state, no water, operable

12. Sample space: Large sample space, can be equipped with 3D sample racks

13. Experimental status data can be transmitted through Ethernet cables

14. Lamp lifespan: UV lamp lifespan can reach over 5000 hours

15. Compliant with standards:ASTM G151 ASTM D4329 D4329 ASTM-D4587.ASTM-G154

在线联系供应商

Other supplier products

| Children's Product Comprehensive Force Tester | The Children's Product Comprehensive Force Tester is a versatile and fully automated instrument designed to evaluate the mechanical strength and sa... | |

| Oil Filter Performance Tester - lab instrument | We are a professional testing instrument manufacturer offering complete laboratory testing solutions. If you need more information or wish to explo... | |

| Fiber Oil Extractor | The Fiber Oil Extractor, also known as the Rapid Grease Extraction Apparatus, is designed for rapid and accurate determination of grease or finish ... | |

| High-precision Material Thermal Conductivity Tester | It adopts the internationally popular method of heat flow meter to detect thermal conductivity and thermal resistance, and realizes fully automatic... | |

| Full Face Thermal Radiation Resistance Test Machine | Introduction Fireman fire-protective clothing is mainly composed of jacket and bibcomposition,may also wear fire protective helmets, fire protecti... |

Same products

| Air Intake Filter Test System | 卖方: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

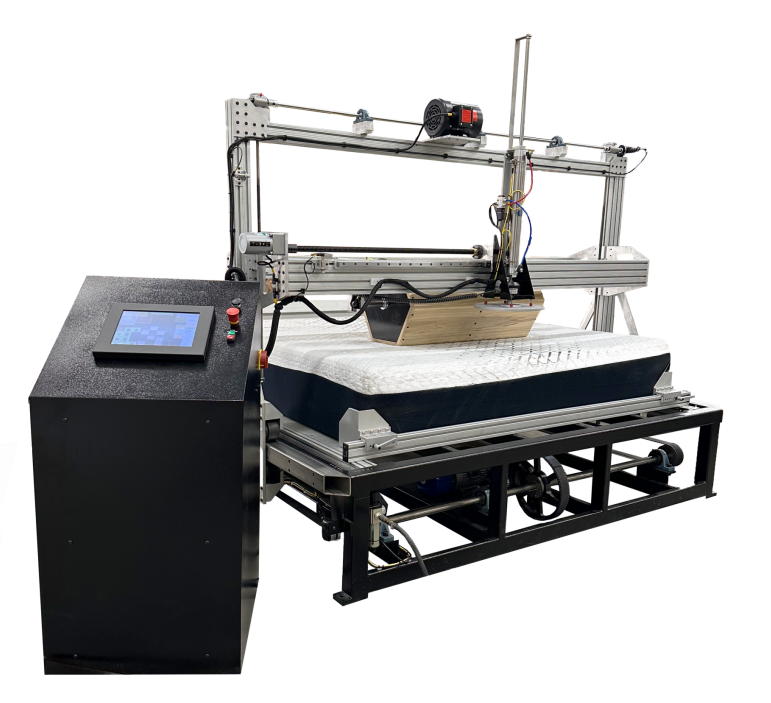

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | 卖方: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | 卖方: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

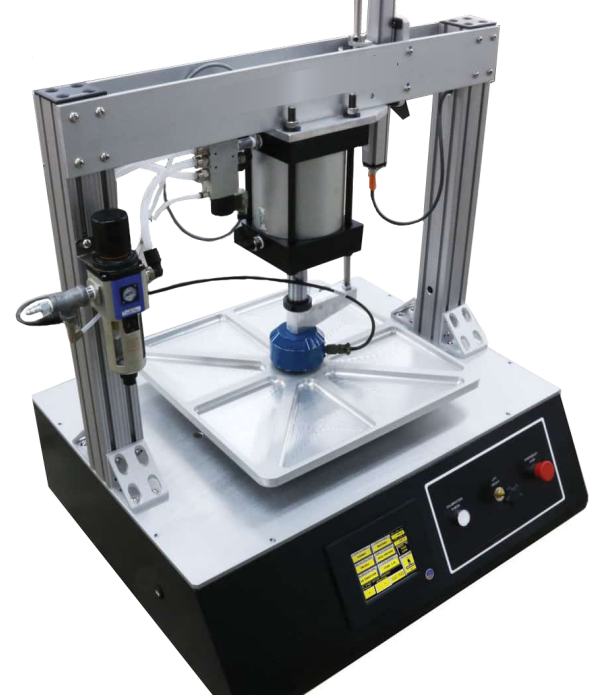

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

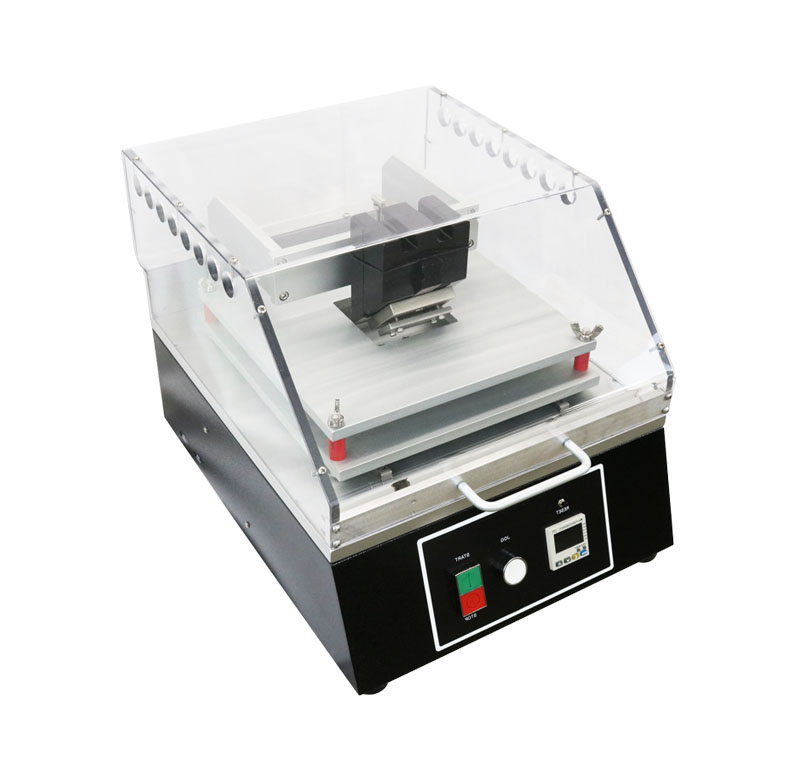

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | 卖方: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |