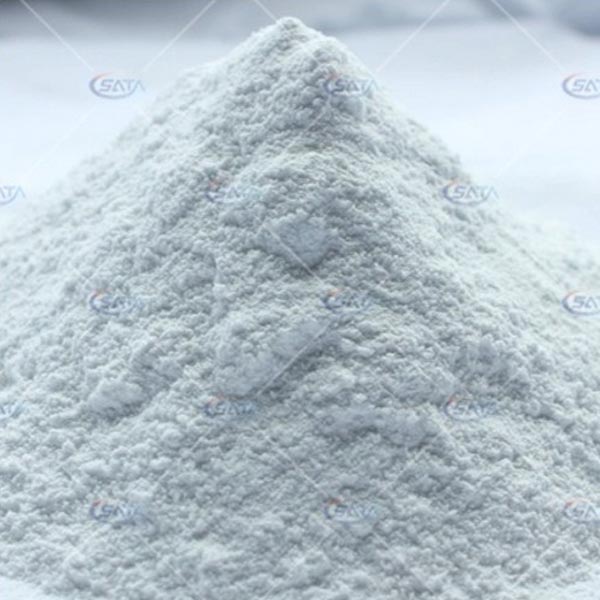

Sodium free refining flux

General Description:

Aluminum alloys containing more than 2 % magnesium become brittle with sodium.

Sodium free refining fluxFeature: This flux is a compact covering and cleaning granulated flux to remove the sodium in the aluminum melting. It generates low dust and low fume during application. It reacts quickly with molten aluminum and removes the alkali metal (Ca, Na, Li, Sr) and non-metallic inclusions (oxides, carbides, borides) and degassing.

Function:

After fusing completed the flux are cooled and they are crushed or ground into ccustomerized particle size.

degassing when injected flux with Argon or Nitrogen.

Applied range:

This flux is used in hypo-eutectic aluminum alloys including those contain high magnesium alloy.

Chemical compositions

Mgcl2 Anhydrous , Potassium Chloride , CaF2 and other salt

Melting Point: 432°C & 483°C

Size of Sodium-Free Refining Flux

Granule 0.8-3.25mm, 1-3mm,Other size can be adjusted according to custom

Package: 1. 2.0kg or 2.5kg or 5kg heat sealed polyethylene (PE) bags into 20 or 25kgs bags or cartons with or without pallet

Advantage:

1) Eco‐friendly flux that reduce dust levels, meet the emission limits of most environmental regulatory agencies

2) Uniform size, reacts fully. Purify the melt improve melt quality.

3) Increases the extrusion speed and die life when extruding profiles

4) Reduces the number of breaks in continuous casting

5) Eliminates edge cracks when rolling high Mg aluminium alloys

6) Free of fluorides. Zero fluoride emissions.

7) Low melting point for rapid dispersion

8) Low application rates, typical 0.15-0.2% of MT aluminium

Notice:

Sodium-free flux should be added to the melt at the temperature of 690-750 Degree Celcius. The recommended application rate should be 0.1 to 0.2% of the melt size. Rebel the melt and remove the dross from the top of the molten metal.

在线联系供应商

Other supplier products

| Recovery Flux | Recovery Flux (SATA-PF-320) General Description of Recovery Flux (SATA-PF-320) SATA recovery flux is a kind of flux used flux for recovering the en... | |

| Reclaimed Fluxes | General Description of Reclaimed Fluxes Reclaimed fluxes is a strongly exothermic flux and used as covering and drossing flux, recovery of grindin... | |

| Potassium Aluminium Fluoride (PAF) | Potassium Aluminium Fluoride (PAF) General Description ofPotassium Aluminium Fluoride(PAF) Molecular Formula: KALF4 /K3ALF6 CAS NO.:14484-69-6 Melt... | |

| Magnesium Chloride Hexahydrate Powder | Magnesium Chloride Hexahydrate Powder General Description of Magnesium Chloride Hexahydrate Powder Chemically, magnesium chloride is represented as... | |

| Sodium Fluosilicate/Hexafluorosilicate (SSF) | Sodium Fluosilicate/Hexafluorosilicate (SSF) General Description of Sodium Fluosilicate/Hexafluorosilicate (SSF) Molecular Formula:Na2SiF6 UN NO.: ... |

Same products

| MECHANIC M35 手机主板维修助焊膏 | 卖方: Phonefix | Mechanic M35 10CC 纳米助焊膏活性高达 98%。高效协同配方,为手机主板、BGA 芯片焊接及常规助焊提供卓越的焊接性能。 产品特点: 1. 纯净配方,无杂质,内外通透细腻。 2... | |

| 蓝睿AS50万能修复霜 氧化点去除 | 卖方: 深圳维客修科技有限公司 | 产品描述 LANRUI AS50 通用修复膏,适用于手机/iPhone 主板氧化点去除、FPC 连接器焊接、屏蔽罩焊接、CPU 镀锡脱锡等。AS50 焊膏用于 PCB 焊接,去除氧化痕迹,提升螺... | |

| Mechanic M35 纳米助焊膏,适用于芯片 IC 维修 | 卖方: 深圳维客修科技有限公司 | 产品描述 Mechanic M35 10CC 纳米助焊膏,适用于手机主板 BGA 芯片焊接维修。Mechanic M35 纳米助焊膏采用环保进口配方,98% 全新高活性、高效协同配方,拥有六大独... | |

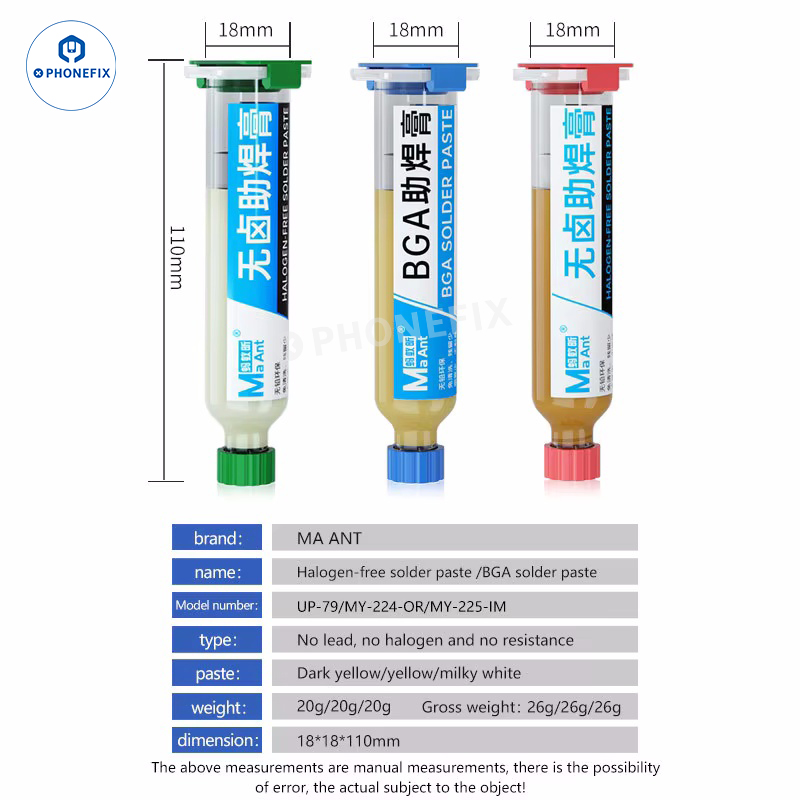

| MaAnt BGA Solder Paste Halogen-free Lead-free Repair Flux | 卖方: Phonefix | MaAnt UP-79 MY-224 MY-225 halogen-free solder paste for mobile phone/electronic circuit board CPU... | |

| JTX Nano Conductive Silver Paste For Phone Screen Line Circuit Repair | 卖方: Phonefix | JTX Nano Conductive Silver Paste repairs iPhone screen/green screen/white screen lines issues cau... |