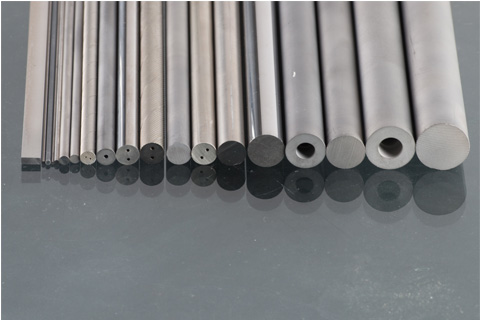

Carbide Rods

Packaging Details:Plastic bag, then protected in foam lay, finally to an outer carton.

Samples Matters:Tungsten carbide rod which can be available from our common regular inventory, can be offered as samples for free. For some carbide end mills and cemented

carbide rod

with irregular customer special required, will be charged. Of course, customers need to pay for the shipping fee. Usually, the lead time of the samples will be within 7working days

Minimum Order Quantity:There is no minimum order quantity of carbide rods for the first trial order. But on the second order, the total amount of carbide rods should be not less than 1000 USD.

Delivery Time:7-15 working days

Features ofCarbide Rods

- Product name: Carbide rods

- Place of Origin: Fujian, China (Mainland)

- Brand Name: Toonney

- Model Number: DIN Cut-to-length Rods

- Type: Carbide rods

- Material: Tungsten carbide

- Application: Carbide end mills, drills, shank, reamers

- Tolerance: Tol. Of Dia.+0.15 to 0.7mm, and length+1 to +2 depends on the size difference.

- Surface treatment: Blank, sand-blasting or polished

- Grade: TU06, TF06, TU08, TU40, TU40F, TU44, TU25, TU45

- Size: Common dia .ranges from 2 to 40mm,and length within 300mm, other size beyond will be specially customized.

- Port: Xiamen

- Payment terms: FOB Xiamen, TT

Application ofCarbide Rods

- TU06 tungsten carbide rod: Ultra-fine grain, high hardness, high strength, fit for making PCB micro-drilling, micro milling cutter and kinds of hard metal solid tools. Re-command material to make milling cutter of which Dia. is 1.2mm and above.

- TF06 tungsten carbide rod: Fit for cutting aluminum and magnesium alloy, copper base alloy, iron-base alloy, plastic, graphite, carbon fiber etc. Recommended material for making drill and mill cutter for aluminum and magnesium material.

- TU08 tungsten carbide rod: High strength and hardness, good for machining acrylic material, recommended material for making PCB drill and big drill of which dia. Is 0.7mm and above.

- TU40 tungsten carbide rod: Recommended material for common drill, end mill, specially good to mill and drill the material common die steel, gray iron, Austenit steel,and alloy

- TU40F tungsten carbide rod: Recommended material for making drill, milling cutter etc, to mill and drill steel, stainless steel, cast iron and aluminum alloy of which hardness is below 50HRC.

- TU44 tungsten carbide rod: Fit for making different specification milling cutters,reamer, carving blades etc. specially performs good in tools cutting in high speed for example in cutting quenched steel, aluminum alloy, titanium alloy etc.

- TU25 tungsten carbide rod: The material for mill and drill tools to machining material heat treatment steel, cast iron, stainless steel.

- TU45 tungsten carbide rod: Recommended material for all kinds end mill, reamer, carving blade etc., performs good in high speed light cutting area,specially fit for quenched steel, aluminum alloy, titanium alloy etc.

Advantages of Carbide Rods

1. Cemented carbide rod has good straightness, excellent hardness, and strength.

2. Toonney cemented carbide rod manufacturer has good pressing and extruding machines.

3. Carbide rods are sintered by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

4. There are carbide rods, cemented carbide rod, carbide end mills, grinding and polished rods in any tolerances.

5. carbide end mills are mainly used for end mills, reamers, drills, countersinks, engraving tools, routers and other rotary tools.

6. The diameter of carbide end mills varies from 0.3mm to 40mm.

7. There are also many different sizes of carbide rods, cemented carbide rod, carbide end mills upon customers’ request and drawing.

在线联系供应商

Other supplier products

| Cutting Tools | Introduction Carbide tools/ carbide cutter are usually used for cutting in machine manufacturing, so it also called carbide cutting tools. The ... | |

| Carbide Tips | Introduction Tungsten carbide tips and carbide saw blade are commonly used cutting tools. The material of carbide tip and carbide saw blade are us... | |

| Carbide Rod With Coolant Hole | Carbide Rodswith One Coolant Duct This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased h... | |

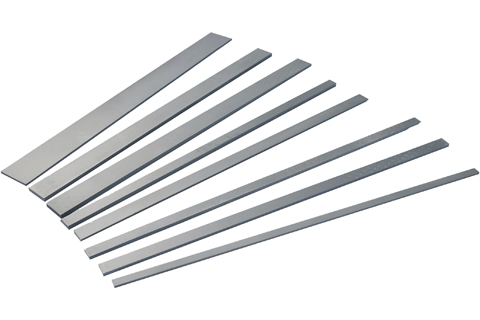

| Carbide Strip | Carbide strip, widely applied in woodworking and stone working. The grade selection is very important, hard grades can last a longer lifetime, howe... | |

| Solid Carbide Rods | Introduction of Solid Carbide Rods Solid carbide rod is mainly made of tungsten carbide, binder metal cobalt and some other functional ingredi... |

Same products

| The Ultimate Tool for Bubble-Free Displays | 卖方: 深圳市维客修科技有限公司 | FORWARD FW-16R除泡机、FW-8R迷你除泡机,在手机、iPhone、iPad、平板屏幕翻新过程中,去除屏幕OCA气泡,最大支持12.9寸屏幕。安全门设计,24V低压风阀配置,有效降低... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | 卖方: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | 卖方: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | 卖方: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | 卖方: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |