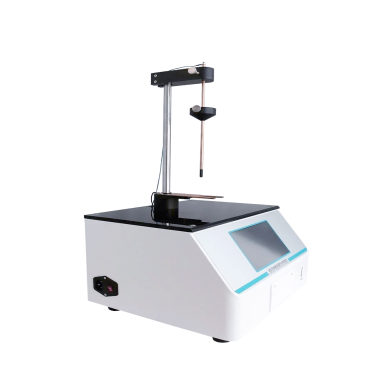

Footwear Cold Insulation Tester EN ISO 20344 / DIN 53351

Product Introduction

Shoes cold resistance testing machine is used to test finished shoes, rubber, sole, synthetic leather, plastic and other test requirements under various low temperature environment to understand the ability of various materials or finished shoes to adapt to low temperature climate or cold terrain area, this instrument is made of rust SUS steel, can be installed with a variety of different test fixtures. In order to meet the different standards of various tests.

Standards

ASTM D17900. EN ISO 20344. HG/T 2411. HG/T 2871. DIN 53351. SATR TM55. Adidas GE-24. GE-57. GB/T 20991-2007 and other standards

Product Advantages

Controlled Low-Temperature Environment: Provides a stable and precise cold environment for conditioning and testing.

Versatile Material Testing: Suitable for testing a wide range of footwear materials and finished shoes.

Standard Compliant: Designed to meet numerous national, international, and industry-specific standards for cold resistance testing.

Accommodates Various Tests: Can be equipped with different fixtures to perform various low-temperature tests (e.g., cold flex, cold impact, thermal insulation).

Wide Temperature Range: Capable of reaching very low temperatures, covering a broad range of cold climate conditions.

Accurate Temperature Control: Features balanced temperature control with high accuracy, uniformity, and minimal fluctuation.

Durable Construction: Made from rust-resistant stainless steel.

Includes Thermal Test Fixture: Equipped with components for conducting low-temperature thermal tests.

Main Parameters

1. Balanced temperature regulator humidity control system

2. Temperature range: -25℃ —— +150℃

3. Temperature fluctuation: ≤±0.5℃

4. Temperature uniformity: ≤2℃

5. Temperature accuracy: ±0.2℃

6. Heating time: +25℃→+85℃ room temperature to 85℃ about 30 minutes no load

7. Cooling time: +25℃→-40℃ room temperature to -40℃ about 50 minutes no load

8. Lead hole: φ50mm 1 (with 1 rubber plug)

9. Heating rate: 3 —— 5℃/min(average), cooling rate: 0.7 —— 1℃/min(average)

在线联系供应商

Other supplier products

| Scott Flex Tester JIS L1096 | Product Introduction: Scott kneading tester is suitable for back and forth kneading resistance of leather, leather and woven materials. One end o... | |

| Catheter Power Injection Flow and Pressure Tester YY 0285.1 | Main Uses The catheter flow and pressure tester for power injection is an important medical device, mainly used to detect key parameters such as f... | |

| Geotextile wear tester丨Geotextile Test Machine | Scope of application: The wear resistance of geotextile and its related products was measured by emery cloth-sliding block method. During the expe... | |

| Current sensor - Accurate Current Sensing | Product Introduction STD designs alternating current (AC) and direct current (DC) sensors for industrial and automotive applications such as elect... | |

| Safety shoe impact testing machine / Safety shoes testing machine | According to the criteria Bs-953.1870 EN-344. ANSI-Z41 CSA-Z195 ISO K88782 EN ISO 20344. ANSI-Z41 BS EN-344 CSA-ZI95 LD50-1994 Product F... |

Same products

| Bottle Wall and Bottom Thickness Tester | 卖方: Standard Group (Hong Kong) Limited | The wall and bottom thickness tester for bottles is a measuring instrument widely used in the pha... | |

| Pinhole Tester / Pinhole Testing Equipment | 卖方: Standard Group (Hong Kong) Limited | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in ... | |

| Cork Puncture and Chip Detection Instrument | 卖方: Standard Group (Hong Kong) Limited | The rubber stopper puncture debris detector is a device specifically used to detect the number of... | |

| Aluminum Ointment Tube Toughness Tester | 卖方: Standard Group (Hong Kong) Limited | The ductility tester for aluminum tubes is a device specifically used to detect the ductility ind... | |

| Vacuum leak tester / Vacuum leak instrument | 卖方: Standard Group (Hong Kong) Limited | Vacuum Decay Leak Tester specializes in the detection of leaks in ampoules, vials, injection bott... |