Type of Flying Shearing Machine

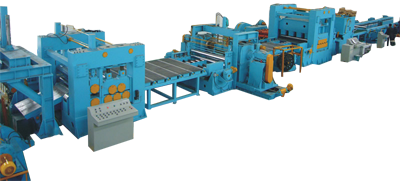

Mechanical flying shear is mainly used for rapid shearing processing equipment of metal plates. The following Rishbin machinery will tell you about the common types of flying shearing machine.

According to the usage of flying shear, flying shear can be divided into two main categories: cutting head flying shear and fixed size flying shear. If the shear mechanism is divided according to the form of the shear mechanism of the flying shear, the widely used flying shears have roller type flying shear, crank rotary lever type flying shear, crank eccentric flying shear, pendulum type flying shear, and crank and rocker type flying shear, etc.

1.Rotary

The rotary flying shearing machine is a widely used flying shear. It is installed on continuous rolling mill or transverse unit to cut steel plate or section steel with thickness less than 12mm. The shear thickness of this kind of flying shear can reach 45mm. The blade of the drum flying shear makes simple circular motion, and it can cut the rolling pieces with speeds up to 15 m / s.

2. Crank rotary lever flying shearing machine

It is used for cutting thick strip or billet. In order to ensure the smoothness of the shear section of the rolled parts after cutting, the flying shear with the blade is usually adopted. The crank rotary lever flying shear is one of these flying shear machines. Because the blade of this kind of flying shear machine is perpendicular to the rolling piece when cutting and rolling, the shear section is smooth. When cutting strip, the inclined blade can be used to reduce shear force. The disadvantage of this flying shear is that the structure is complex, the dynamic characteristics of the shear mechanism are not good, and the movement speed of the rolled parts should not be too fast. A crank-link flying shears used in a small section steel plant with a speed of less than 5m/s and a thickness of 30-70 shearing pieces.

3. Crank eccentric flying shearing machine

The blades of this kind of flying shears move by translation. The crankshaft of two arms is hinged in the boring of eccentric shaft, with a certain eccentricity e. The crankshaft of both arms is also hinged with the guide frame by connecting rod. When the guide frame rotates, the crankshaft of the two arms rotates together at the same angular speed. The blade is fixed to the tool holder, and the other end of the tool holder is hinged to the swing bar, which is hinged to the frame. By means of the double-arm crankshaft, tool holder and swing bar, the blade can move in the shear curve in a manner similar to the horizontal movement, and the smooth shear section has been obtained. By changing the ratio of the angular velocity of the eccentric shaft to the crankshaft of the two arms, the radius of the blade track can be changed to adjust the measured length of the rolled piece. This kind offlying shear machineis installed behind the continuous billet mill to shear the billet.

4. Pendulum flying shears

The pendulum flying shear is used to cut the strip with a thickness less than 6.4 mm. The blade is similar to translational motion in the shear area, and the shearing quality is better. The upper tool holder is articulated with the main crankshaft. The lower tool rest is connected with the main crank shaft through the sleeve type connecting rod, the outer eccentric sleeve and the inner eccentric sleeve. The lower tool holder can slide in the slot of the upper tool holder. The eccentricity between the upper and lower knife rest and the main crank shaft is E1, and the eccentricity position is 180 degrees. When the main crank shaft rotates, the upper and lower tool holders work relative motion to complete the shearing action. On the main crank shaft, there is an eccentric E2. The eccentricity is connected to the axle head of the rocker by a connecting rod, and the rocker is connected with the upper tool rest through a connecting rod. Therefore, when the main crank shaft rotates, the upper and lower tool frames are swung back and forth by means of connecting rods, rockers and connecting rods. As the upper and lower tool holders can swing up and down, they can cut the rolling pieces in motion.

5. Crank rocker type flying shears

This flying shear is also known as the Shroman flying shear, which is used to cut cold rolled strip. Because the total energy fluctuation of flying shear is small, it can work at a speed greater than 5m / S. The upper tool rest of the crank rocker flying shear is articulated through the eccentric pivot and the lower tool carrier. Under the driving of the crankshaft and the upper tool rest, the lower tool carrier is reciprocated by the eccentric shaft. When the eccentric position of eccentric shaft and eccentric sleeve is changed, different times of empty cutting can be obtained.

在线联系供应商

Other supplier products

| Light Gauge Cut To Length Lines | is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to lengt... | |

| Steel Slitting Line/Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Operating Procedure of Steel Slitting Line... | |

| Type of Flying Shearing Machine | Mechanical flying shear is mainly used for rapid shearing processing equipment of metal plates. The following Rishbin machinery will tell you abou... | |

| Light Gauge Slitting Lines | RISHBIN Light Gauge Slitters for pre-painted/coated coils, max. thickness of up to 3mm, max. width of up to 2200mm, and speed of up to 300 m/min.... | |

| Steel Sheet Slitting Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Metal steel sheet slitting machine main typ... |

Same products

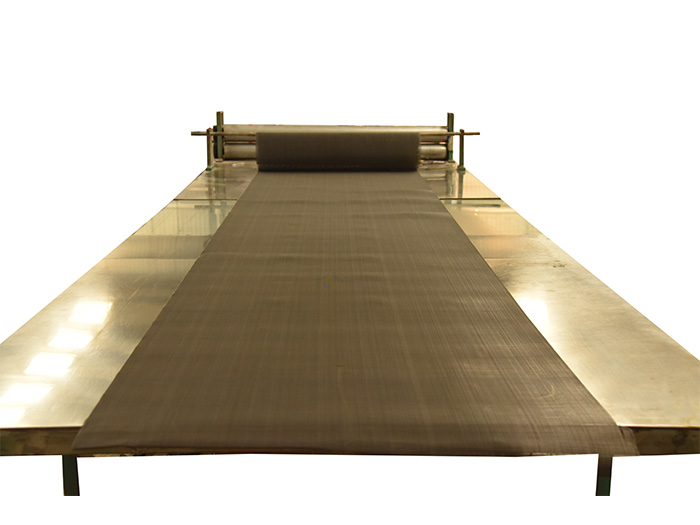

| Plain Steel Mesh | 卖方: Hebei Jiushen Wire Weaving Co., Ltd | Plain steel wire meshis a kind of wire mesh that woven from various kinds of carbon steel wires. ... | |

| 18650 Nickel Strip Phone Battery Spot Welding Connector Sheet | 卖方: 深圳市维客修科技有限公司 | Description 3GOA high purity 18650 battery nickel strip lithium battery connector 1M 5M ... | |

| 第二十六届广州国际不锈钢工业展 | 卖方: 广州巨浪展览策划有限公司 | 第二十六届广州国际不锈钢工业展 邀请函 主管批准单位: 中华人民共和国商务部外贸司 广东省对外贸易经济合作厅 主办承办单位: 广州巨浪展览策划有限公司 协办单位: 天津市... | |

| Centrifugally cast Chromium-Nickel alloy tubes | 卖方: Nanjing Xinshuo Mechanical Equipment Co., Ltd. | Centrifugally cast Chromium-Nickel straight alloy tubes | |

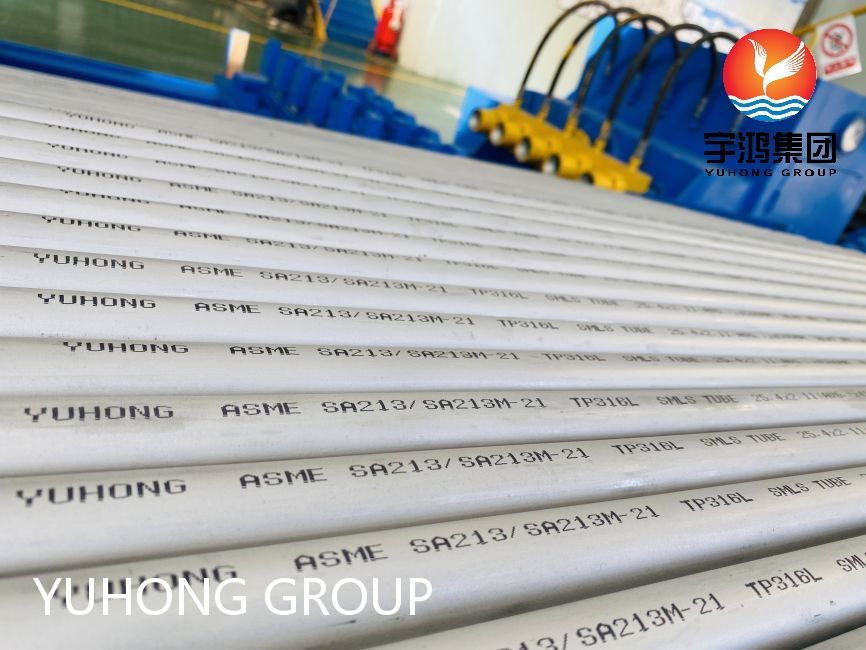

| STAINLESS STEEL PIPE/TUBE | 卖方: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | STAINLESS STEEL PIPE/TUBE Stainless steel pipe/tube is one of the most widely used in manufactur... |