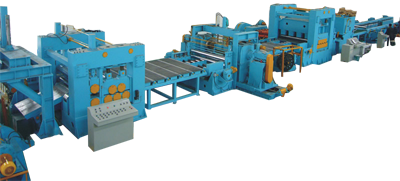

Based on much experiences on providing quality, cost-effective and long lasting roll forming systems

Metal steel sheet slitting machine main types:

1. Simple metal slitter2. Liquid pressure semi-automatic working metal slitter3. Fully automatic metal slitterMetal

steel sheet slitting machineis divided into the following according to the actual size of the processing material:1. Sheet metal strip slitting machine2. Medium plate metal strip slitting machine3. Thick metal strip slitting machineAccording to different regions, the name of themetalsteel sheet slitting machinefor metal strip steel is different. It is mainly divided into:1. Metal disc shears2. metal rolling shears3. slitting machine4. metal slitting machine5. metal shearing machineThe components of the metal strip slitting and slitting machine are as follows: feeding trolley, uncoiler, leveling machine, slitting machine, waste edge winding machine, tensioning machine, winder, unloading device and other components.

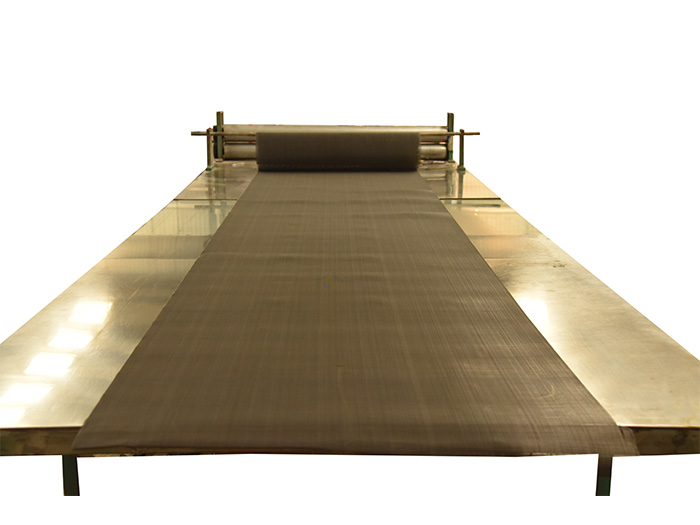

Metal strip slitting machine main functions:

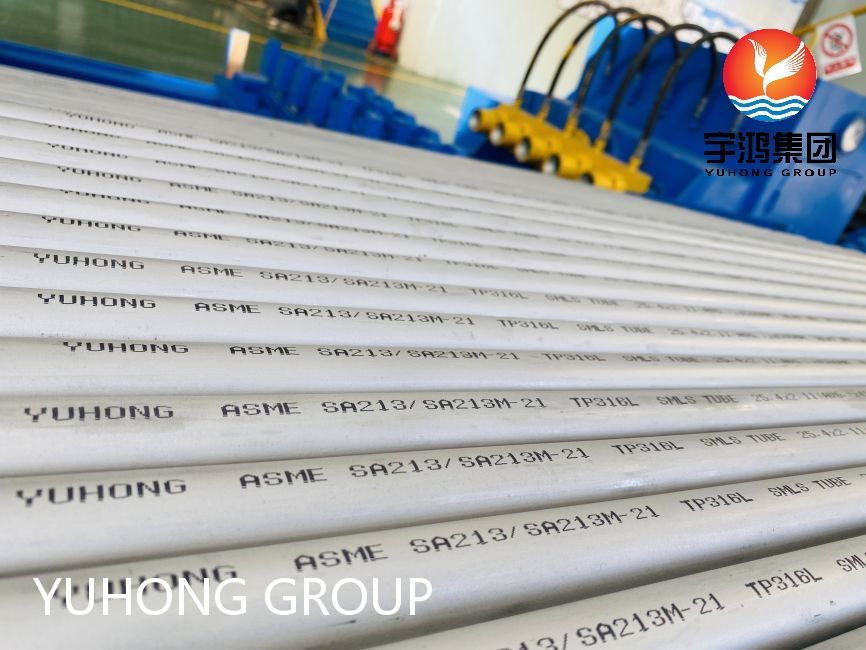

The main slitting material for the metal strip slitting slitter is metal coils, such as strip steel or stainless steel, and the metal strip is slit into a number of required strips. It is suitable for the processing of cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and all kinds of metal coils after surface coating. Metal strip slitting machine is mainly used for steel sheet processing manufacturers of steel rolling mills, electrical appliances, automobiles, containers, household appliances, building materials, stampings and other sheet metal processing industries. The slitting machine is made of unwinding (unwinding), reel positioning, Slitting, winding (winding) and other equipment. It can process all kinds of metal plates such as cold-rolled, hot-rolled coil, silicon steel plate, stainless steel plate, and aluminum plate.