Rubber Mooney Viscosity Tester 丨Mooney Viscometer

Test principle:

The Mooney viscometer is used to measure the viscosity of rubber under specific conditions. In the test, the rubber sample was loaded into the mold cavity of the Mooney viscometer and the motor was started after preheating, and the rotor began to rotate and a certain shear torque was applied. At the same time, the rubber sample produces an equal and opposite resistance moment, which is displayed by the dial indicator installed at one end of the worm or directly through the computer, that is, the Mooney viscosity value.

Reference standard:

GB/T 1232 unvulcanized rubber - Determination of Mooney viscosity

GB/T 1233 rubber compound -- Determination of initial vulcanization characteristics -- Mooney viscometer method

HG-T 3242-2017 Rubber Mooney viscometer

ISO289 unvulcanized rubber -- determination by shear disc viscometer

ISO667 rubber compound - Determination of initial vulcanization characteristics - Mooney viscometer method

Technical parameters:

Measurement and control temperature range: normal temperature ——200℃

Torque measuring range: 0-100 Mooney value

Calibration accuracy: 100±0.5 Mooney value

Rotor speed: 2±0.02 RPM

Measurement time: 0-200 points

Ambient temperature: 0-35℃

Relative humidity: <80%

Test pressure: 11.5KN±0.5KN

Air pressure: 0.45-0.6MPa

Test requirements:

1) Scope: This specification specifies the test method of Mooney viscosity of rubber compound.

Note: Measuring range includes: Mooney viscosity.

2) Test tools: Mooney viscometer, electronic scale, scissors, heat insulation gloves

3) Sample requirements: Cut two rubber samples with a diameter of about 45mm and a thickness of about 3mm from the bubble-free rubber material, one of which has a circular hole with a diameter of about 8mm in the center of the sample (two pieces of rubber material weigh about 16g)。

4) Test conditions: the rubber material can be tested for more than 2 hours under laboratory conditions after processing, but not more than 10 days.

在线联系供应商

Other supplier products

| Industrial chillers | Applicable Standards Industrial chillers adhere to global safety and performance regulations, including: ASHRAE 15(Safety Standard for Refrig... | |

| Fabric Wrinkle Bending Tester / AATCC 128 / Textile Tester | Overview The Fabric Wrinkle Bending Tester is a specialized instrument used to assess the wrinkle recovery properties of various textile fabrics. ... | |

| Infusion Pump Flow Rate Tester GB 8368 | Compliance Standards GB 8368 - 2018 Disposable Infusion Sets, etc. Main Uses The infusion set flow rate tester is an instrument specifically des... | |

| Fabric Drying Tester | Product Introduction: This device is developed for the automatic test of "dryness" method A and method B specified in JIS L 1096 (Fabric test meth... | |

| Geotextile wear tester丨Geotextile Test Machine | Scope of application: The wear resistance of geotextile and its related products was measured by emery cloth-sliding block method. During the expe... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | 卖方: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | 卖方: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

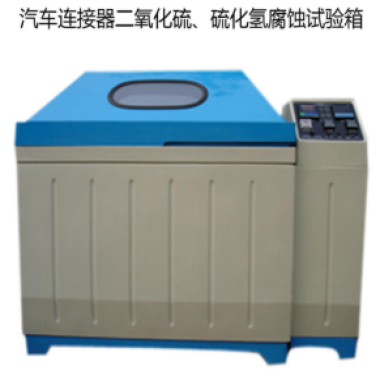

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | 卖方: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | 卖方: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | 卖方: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |