Grinding Head G - Round Shape Shape (RO)

KEYING Mounted Head is made of imported raw materials and special equipment with automatic production and excellent quality. These products are designed to meet the needs of individual grinding tool applications and come in a wide range of particle types, granularity, hardness levels and shapes. To select the correct installation point, consideration must be given to the material, main application area and specific operational requirements. We will explain to you the appropriate materials for the different types (abrasives and binders) and the task at hand.

Features of Grinding Head G - Round Shape Shape (RO)

Designed to meet individual grinding tool application needs, these products come in a broad range of grain types, grit sizes, hardness grades and shapes.

The mounted points are manufactured on modern production lines to high standards of dimensional accuracy and stability, consistent quality and close tolerances.

To select the correct a11 mounted point, the material, main fields of application and specific operating requirements have to be taken into consideration.

Grinding Head G - Round Shape Shape (RO) Applicable Industries

Applications

Surface: Edges and difficult reached angels, Deburring, Grinding, Welding removing, Finishing, Prepare for grouting, Roughening

Material Apply: Steel, Cast steel, Stainless steel, Non-ferrous metals, Cast iron, Plastics, Rubber, Woo

Matching Tool Drives:

Flexible shaft drive

Straight grinder

Safety Instructions of Grinding Head G - Round Shape Shape (RO)

How To Grinding Head G - Round Shape Shape (RO)

Instructions:

Please try to choose operation indoors environment and wear protective guards and goggles.

Never to exceed the recommanded maximum permitted rotational speed for safety reasons.

In order to have a gppd syocl removal rate, quality of surface and thermal laoding on the workpiece, the best performace would with a recomended cutting speed at 15-20m/s.

Don't push and increase the pressure during the processing to achieve a finner surface looking, but try to switch to diffirent grit flap wheels.

Safety Warning:

The clamping lenght between shank and grinders should be more than 15mm.

Never exceed the maximum safe speed when the shank is extra long. Try to consult your sales to check the safety rotating speed before use.

As a reliable abrasives factory, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| Felt Polishing Wheel Drum | The Felt Polishing Wheel Drum is particularly suitable for polishing larger surfaces. The steel wool polishing wheelstructure is designed to fit th... | |

| Flap Wheel M14 | KEYING M14 nylon flap wheelhas excellent craftsmanship and is at the leading level in the industry, and imported high-quality glue is used in the m... | |

| Flap Wheel - Spherical Shape (RO) | On the mounted sanding flap wheel for angle grinder, the flap made of coated abrasive is arranged radially around the tool axis in a fan-shaped str... | |

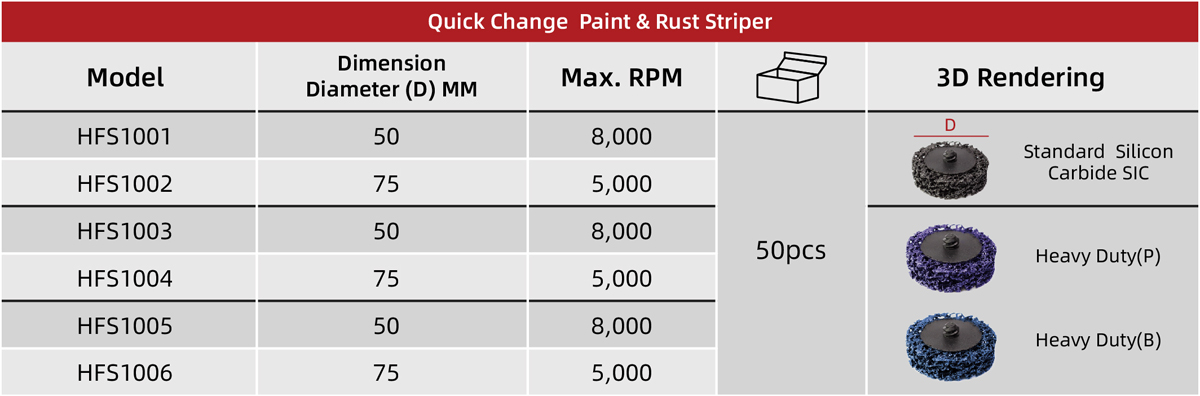

| Aluminium Oxide Quick Change Paint Striper (AO) | Aluminum oxide is a popular choice among industrial professionals because of its fast cut-rate and long life. This mineral makes a tough, durable a... | |

| Grinding Head G - Triangular Trapezoid Shape (TT) | KEYING Mounted Head is made of imported raw materials and special equipment with automatic production and excellent quality. These products are des... |

Same products

| YCS 专业手机维修温控屏幕拆卸工具 | 卖方: Phonefix | YCS 专业手机维修温控屏幕拆卸工具 YCS 多功能拆框机可安全拆卸平面和曲面 LCD 屏幕,并拆卸后盖。其通用摄像头孔可快速拆卸屏幕,且不会损坏手机摄像头。 特点:1. 多用途:YCS 多... | |

| AiXun HT316 Dual-Channel Hot Air Gun and Soldering Iron for Fast Repairs | 卖方: 深圳市维客修科技有限公司 | AiXun HT316 1400W 智能数显热风枪烙铁,二合一 BGA 返修台,适用于手机维修。配备 T225 和 HK14 双通道手柄。焊台通道兼容 C030 (30W)、C080 (80W)... | |

| Upgrade Your Repair Process with HD Vision | 卖方: 深圳市维客修科技有限公司 | H2630VT-D50 200万像素高清工业相机,配备HDMI 产品特点: 1. 三个同步输出接口:HDMI + VGA + Type-C,兼容性强,支持多设备同时观看。 2. 高清成像:采... | |

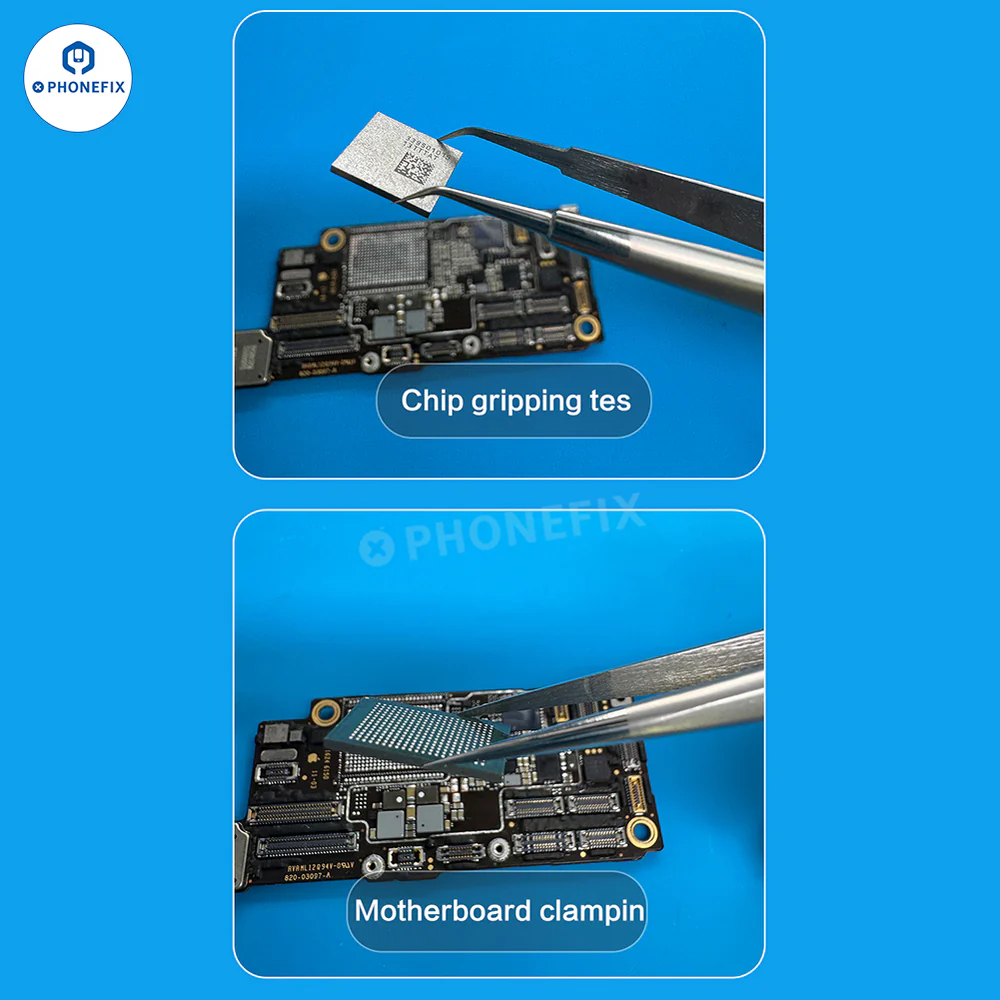

| Engineered for the Toughest Repairs in Tight Spaces | 卖方: 深圳市维客修科技有限公司 | PHONEFIX i2C NS-01 NS-02 NS-03 NS-04 超合金精密镊子,适用于夹持小零件,以及在手机主板等狭小缝隙中进行焊接和维修工作。DIYPHONE 2.5D 3D 镊子采... | |

| 2UUL DA19 RollStop Solder Blade for Mobile CPU and IC Soldering | 卖方: 深圳市维客修科技有限公司 | 2UUL DA19 RollStop 焊锡刮刀套装,适用于手机 CPU 焊接维修。2UUL DA19 焊锡刮刀套装采用手工抛光刀片和防滚设计,易于上锡,刮除焊膏时不会损坏 BGA 模板。适用于手... |