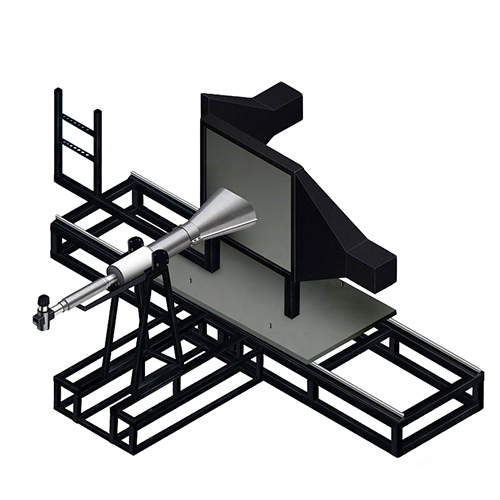

Catalytic Debinding Furnace

Description

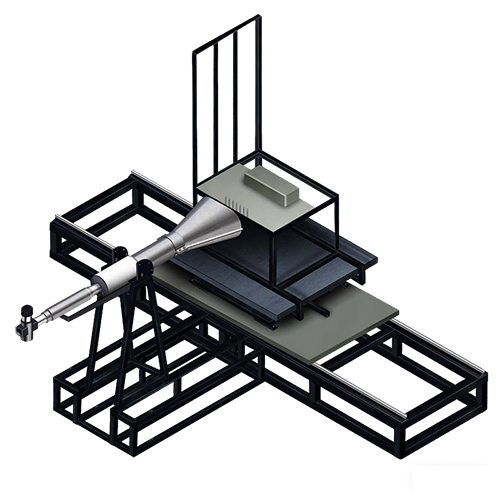

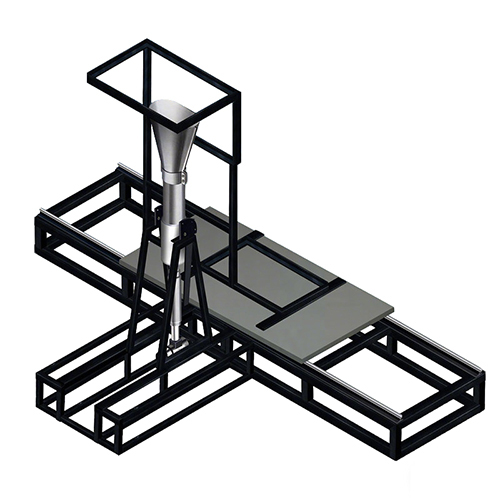

Catalytic debinding furnace is mainly used for catalyst debinding process of metal powder injection molding (MIM) parts.

Technical Features

1. The furnace is made of stainless steel 316L, which has god anti-corrosion performance and appearance.

2. It uses special muffle design and gas distribution, so the uniform gas flow result a good debinding effect.

3. The special exhaust gas treatment is an environment friendly design, which can treat the extra HNO3 and exhaust gas.

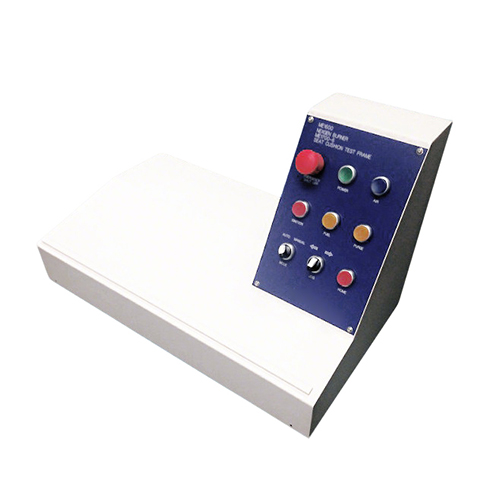

4. It works by using touch screen operation and PLC central control, which makes the operation simple and reliable.

5. Catalytic debinding tube furnaces have the functions of over temperature and over pressure fault alarm, mechanical automatic pressure protection and interlocking, which forms a highly safe furnace.

6. It has remote control operation, remote malfunction diagnosis and remote program update functions.

Send product request

Other supplier products

| Gas Pressure Sintering Furnace | Gas pressure sintering furnace is mainly used for vacuum sintering and pressure sintering of Sic, Si3N4 and other ceramic parts. | |

| Horizontal CVD Furnace(C) | Horizontal CVD furnace (Carbon) is applied for composite material CVD that used hydrocarbon gas (like C3H8) as carbon sources, which works on CVD a... | |

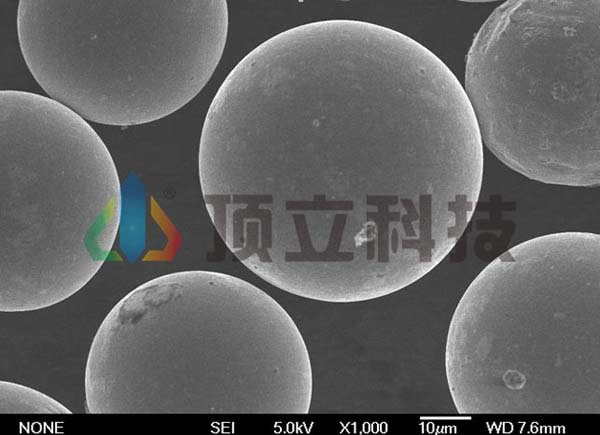

| Spherical Aluminum Alloy Powder | Based on technology innovation and professional service, ACME provides high-end industrial heating equipment for customers in various fields, such ... | |

| ACME Rotary Furnace | DescriptionRotary furnace is mainly used for metal salt calcination and metal oxide reduction process, such as APT calcination, blue tungsten reduc... | |

| Mesh Belt Sinter Furnace | DescriptionMesh belt sinter furnace is mainly used for high temperature sinter of powder metallurgy ferrous and copper parts, such as oil bearing, ... |