China PM Parts Sintering Oven OEM

Description

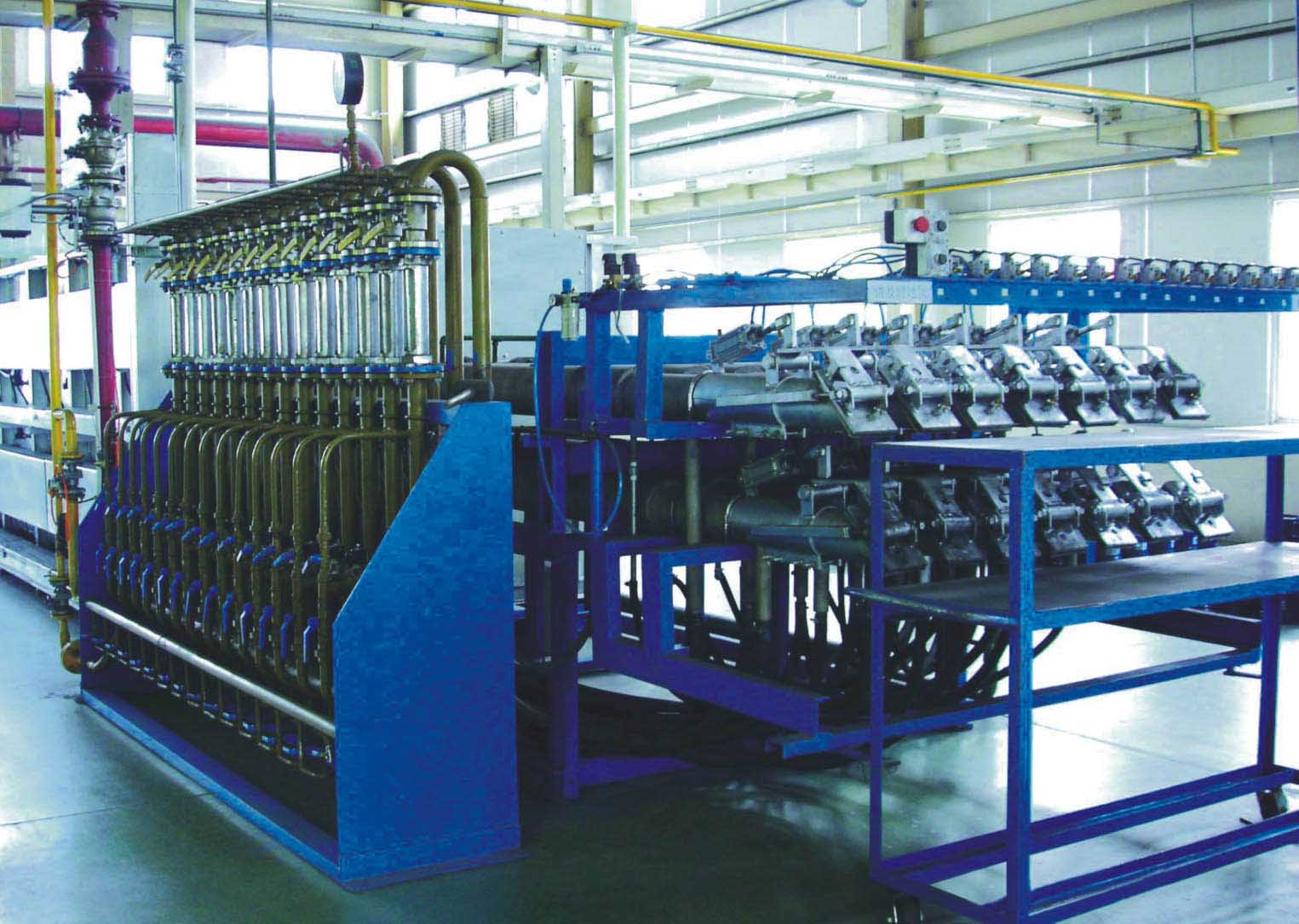

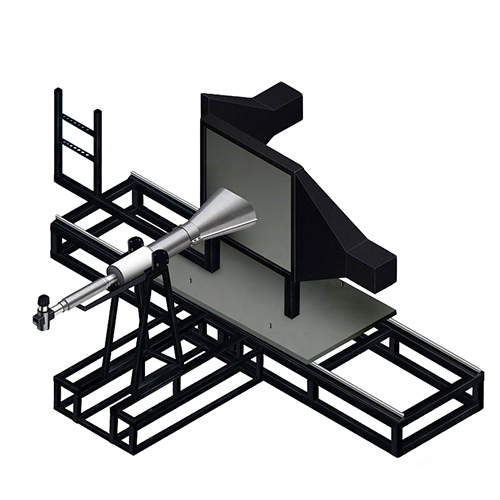

Mesh belt sinter furnace is mainly used for high temperature sinter of powder metallurgy ferrous and copper parts, such as oil bearing, gear, clutch plate, bushing, sleeve, etc.

Technical Features

1. The furnace is configured with RBO rapid binder removal system as required.

2. Module type heating element is used , which is convenient for maintenance and replacement without stop the furnace.

2. All fiber refractory structure guarantees faster heating rate and less energy consumption.

3. Mesh belt sintering furnace uses hanging roof structure, which is convenient for maintenance and replacement of muffle.

4. Fast cooling system is available that is mainly for hardening the ferrous material.

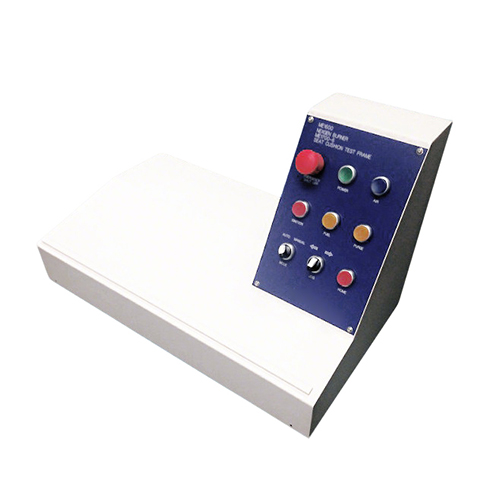

5. It has functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Send product request

Other supplier products

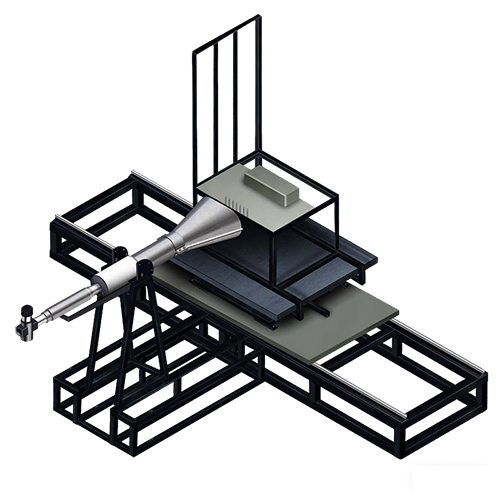

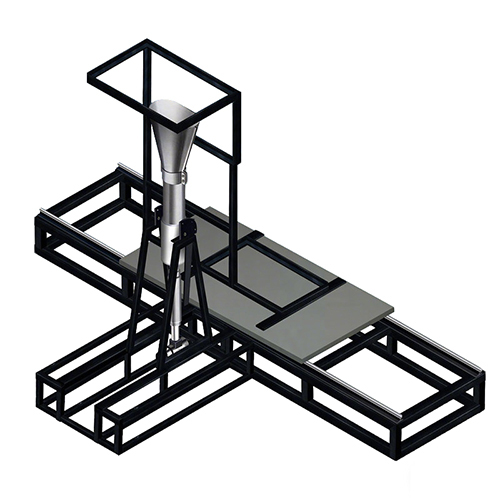

| 18-Tube Automatic Reduction Furnace | DescriptionMulti-tube furnace is mainly used for metal powder (like tungsten, moly, etc) reduction.Technical Features1. Multiple tube heating guara... | |

| China PM Parts Sintering Oven OEM | DescriptionMesh belt sinter furnace is mainly used for high temperature sinter of powder metallurgy ferrous and copper parts, such as oil bearing, ... | |

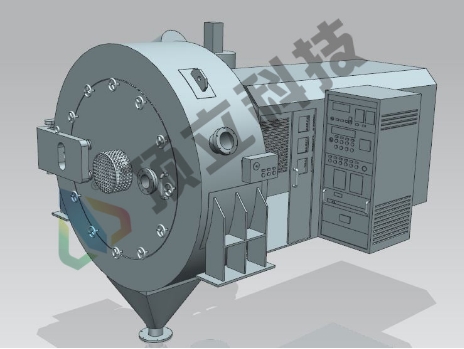

| Plasma Rotating Electrode Atomization Equipment | DescriptionPlasma rotating electrode atomization equipment processes metal or alloy powders with good sphericity, fewer defects, uniform and narrow... | |

| Vertical Bottom Loading Vacuum Brazing Furnace | DescriptionVacuum bottom loading furnace is used for vacuum brazing of materials like non-ferrous metal, stainless steel, titanium alloy, high temp... | |

| Vacuum Aging Furnace | ApplicationIt is used for vacuum aging and re-crystallize annealing after solid solution of tool steel, die steel, high speed steel, super high str... |