Magnetic Flux Leakage Testing Equipment

Magnetic Flux Leakage Testing Equipment

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testingis a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

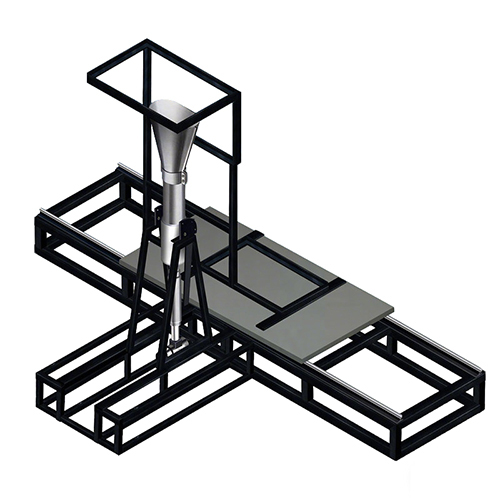

Magnetic Flux Leakage Testing Equipment Principle

The basic magnetic flux inspection principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors.

The MFI mag flux testing method is a highly automated magnetic flux testing technology. The magnetic flux leakage principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, magnetic particle detection technology is commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage ndt detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

Benefits of Magnetic Flux Leakage Testing

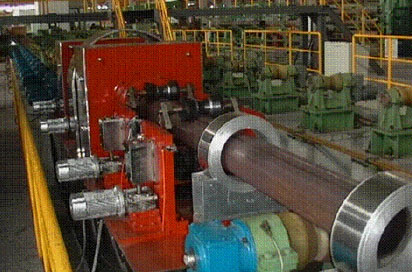

MFL(Magnetic Flux Leakage Testing) is also good at detecting pitting and is highly sensitive, making it a valuable tool in the inspection of materials. With high-speed inspection capabilities, MFL is an ideal method for inspecting ferromagnetic materials that are finned tubes, such as those used in power plants and oil fields.

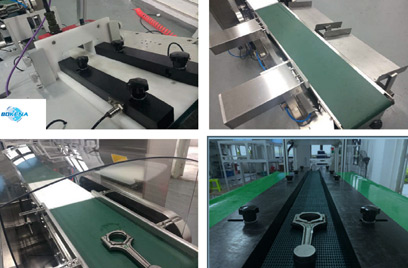

Application of Magnetic Flux Leakage Testing

The use of MFL technology has been shown to improve safety by reducing the risk of catastrophic failure of pipelines, which could result in spills or other dangerous events. In addition, MFL technology has been shown to reduce operating costs by helping operators avoid costly shutdowns caused by corrosion or other material loss.

In addition to its use in oil & gas applications, magnetic flux leakage ndt testing has been applied to assets in other industrial sectors including power generation plants; chemical manufacturing facilities; paper mills; steel mills; transportation systems (including railroads); offshore drilling platforms; defense installations; and municipal water treatment facilities.

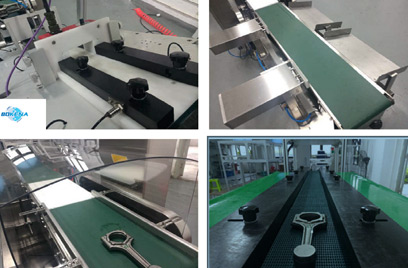

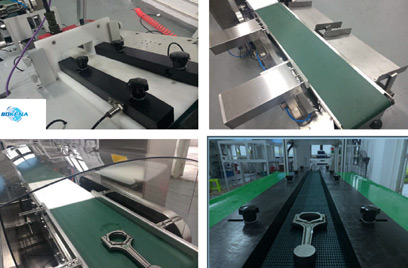

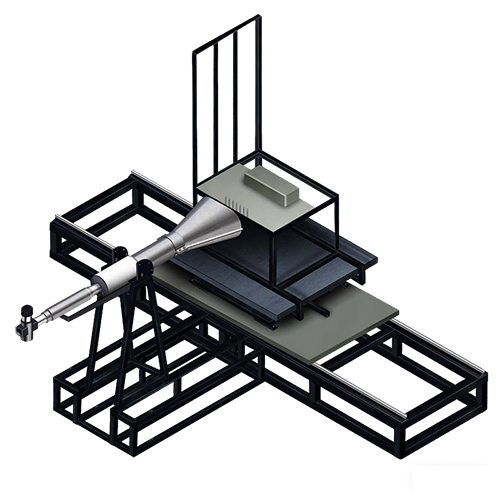

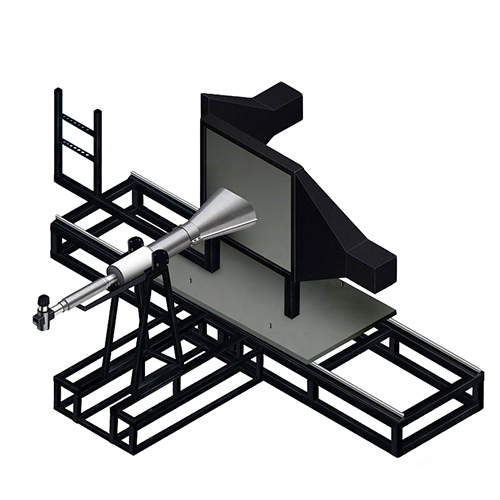

Benchtop Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

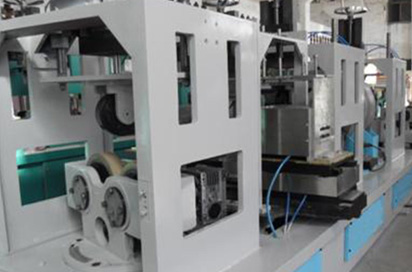

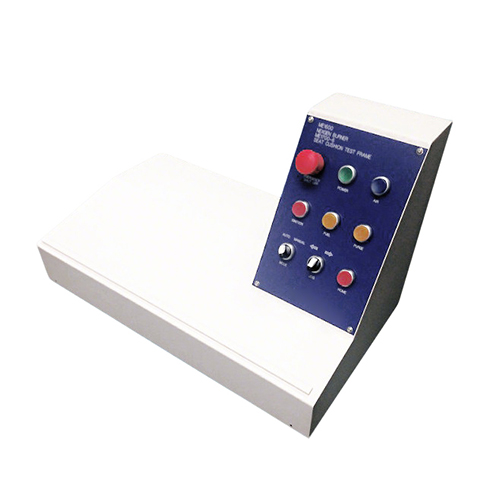

As a ndt equipment supplies ltd, we have been committed to developing and manufacturing high-quality and high-performance ndt testingequipment to provide customers with the best quality service.

If you want to know more about magnetic flux leakage testing procedure, please visit our website.

Send product request

Other supplier products

| EDM Notch | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... | |

| Eddy Current Testing Equipment | Bokena is one of the most professional eddy current test equipment suppliersin China. We have been devoted to produce ect testing equipmentand ect ... | |

| Drill Pipe Magnetic Flux Leakage Detector MFL-308 | Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so Detection speed: 6-20 m / min Acceptance criteria: American Petroleum Institute ... | |

| GTET-02 Cylinder Liner Eddy Current Testing Machine | We have eddy current machine for sale! GTET-02 Cylinder Liner Eddy Current Testing Machine Introduction The rate of missed standard defect is 0... |