Fully automatic spinneret mirror inspection instrument

The Fully Automatic Spinneret Mirror Inspection Instrument (Detector) is designed for automatic inspection of chemical fiber filament spinnerets, staple fiber spinnerets, and industrial yarn spinnerets of various shapes and specifications, including round, square, and rectangular dies. The instrument can also inspect spinning plates, spinneret mouthplates, and other specialized dies for hole shape, size, and blockage.

By analyzing the shape, size, and arrangement of spinneret holes, this instrument can detect any hole within the effective vertical and horizontal ranges, ensuring comprehensive and accurate inspection.

Software part![QQ QQ]()

Manufacturing Standards

Produced according to GB/T19001-2016 / ISO9001 quality management system.

Mechanical and electrical design conforms to GB 5226.1-2008 standards.

Instrument Features

1. Mechanical System

Three-Axis Motion Control: Uses an automatic X-Y-Z three-axis platform (orthogonal robot) with imported AC servo positioning. Each axis features a precision ball screw drive, ensuring low noise, high precision, and repeat positioning accuracy up to ±0.01mm.

High-Resolution Lens: Equipped with a high-pixel lens with low distortion. No lens replacement is required when switching magnifications.

Industrial Camera: High-speed, high-resolution black-and-white industrial camera ensures distortion-free image capture for accurate measurement.

High-Strength Loading Fixture: Metal fixtures and table provide excellent load-bearing performance, easy replacement, and ensure flatness via precision grinding.

Display Interface: Built-in display allows real-time observation of the inspection process.

2. Electrical & Software System

Advanced Image Processing: Detects hole diameter, area, roundness, fouling rate, and other parameters automatically. Position of unqualified holes is recorded.

Custom Spinneret Templates: Users can input spinneret parameters for calibration.

Automatic Focusing: Lenses automatically adjust focus, improving inspection efficiency.

Data Management: Test results are stored in a database for easy recording and analysis.

Optimized Detection Path: Detection rate per hole: 0.2–1s, depending on spinneret specifications.

Flexible Operation: Different spinnerets can be tested by loading corresponding template files.

Industrial Control Computer: Equipped with X-Y-Z control, I/O card, adjustable light source controller, keyboard, and mouse for fast data transmission.

LED Illumination: Long-life LED light source ensures uniform lighting through spinneret holes for high-quality image capture.

All-in-One Design: High-strength metal construction with convenient spinneret fixture replacement.

Detection Method

Hole-by-Hole Scanning: Fully automatic scanning of all spinneret holes using computer-controlled image processing.

Automatic Defect Handling: Unqualified holes are recorded, can be cleaned with compressed air, or marked using a coaxial light source.

Full Automation Definition: The microscope automatically inspects and records position coordinates of each hole, including abnormal holes. Air blow cleaning and visual marking ensure precise defect management.

Send product request

Other supplier products

| Automatic dry cleaning tester | Automatic dry cleaning testers have wide applications in multiple fields, primarily including the following: Textile Industry: Testing the appeara... | |

| Upper Leather Flexing Tester | The Upper Leather Flexing Tester evaluates the flexing endurance and resistance to cracking of shoe upper materials (vamp leather) by applying repe... | |

| Automobile Headrest Strength Tester manufacturer | 1. Product Overview The Automobile Headrest Strength Tester is a precision testing system designed to evaluate the static strength and load-bearin... | |

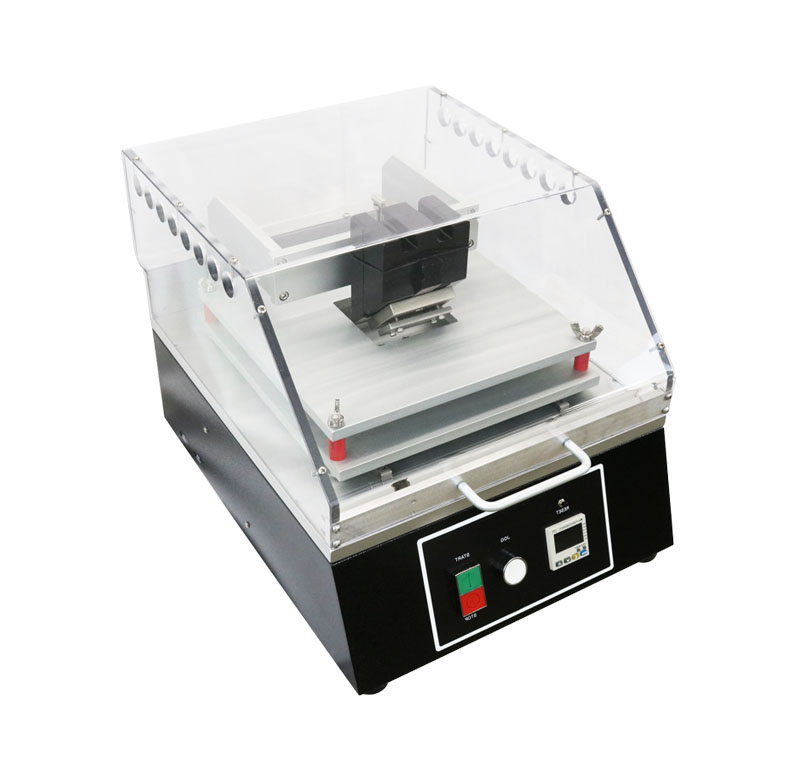

| Crockmeter/Rubbing Fastness Tester - Test Equipment | Electronic rubbing colour fastness testeris designed with a base, rubbing rotation mechanism and a counter. Fix the specimen and sand paper with th... | |

| Washer and Dryer | The Washer-Dryer Combo is a space-saving solution for automated laundry processing, combining washing and drying functions in a single appliance. ... |

Same products

| Air Intake Filter Test System | Seller: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

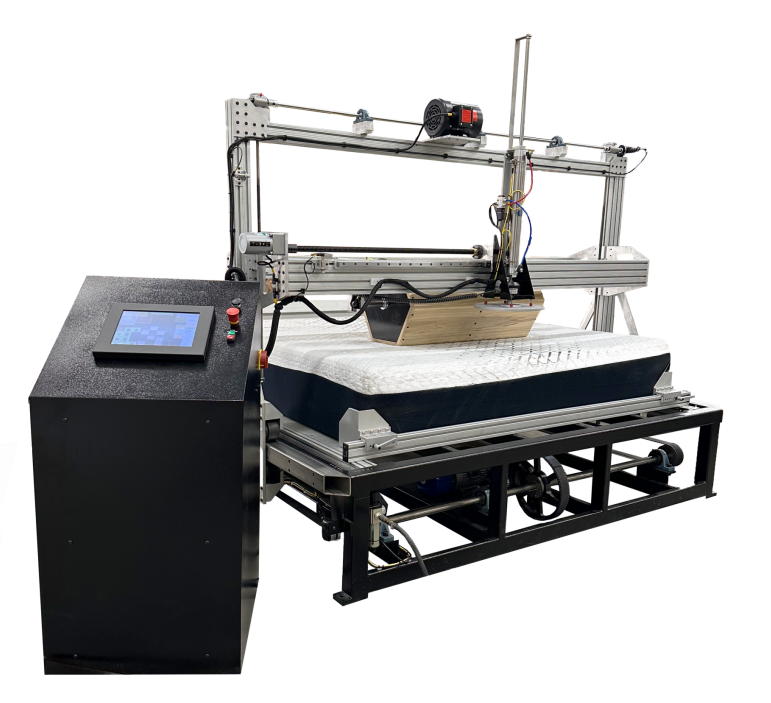

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Seller: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Seller: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

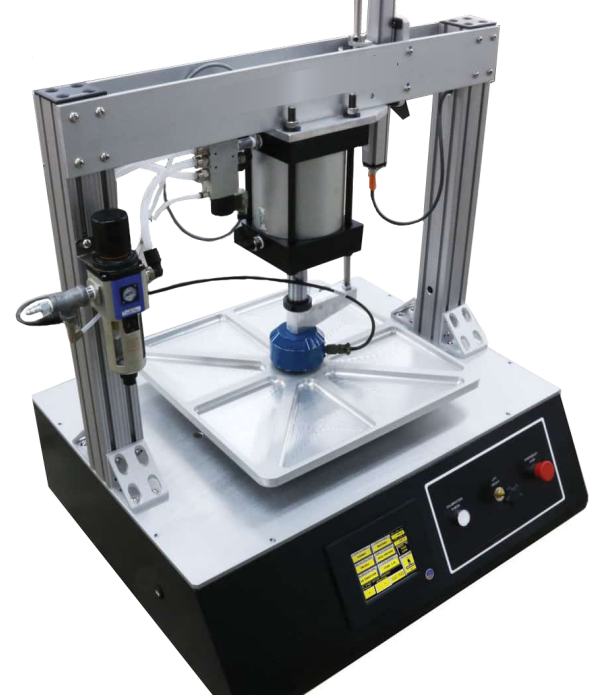

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Seller: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |