Burning Manikin System

The burning manikin system is used to test the overall thermal protection performance of protective clothing.Complete combustion manikin system, which consists of combustion chamber, burning manikin and gas control system and other components.

Application

The Burning Manikin System is primarily applied in the following areas:

Fire Environment Simulation: This system simulates high-risk fire environments, realistically recreating flashover scenarios. Using a burning manikin testing system and accompanying software, it evaluates the flame-retardant performance of protective clothing.

Thermal Protection Performance Assessment: By placing thermal sensors on the manikin model, it measures and calculates the heat and temperature transmitted through the clothing to various parts of the manikin's surface, thereby predicting the possible locations and extent of burns.

Fire Environment Research: This system helps researchers analyze the heat transfer mechanism between the heat source, clothing, and the human body in a fire environment, improving the thermal protection performance of protective clothing.

Firefighter Protection: Through burning manikin testing, it evaluates the heat insulation performance of fire suits, optimizing designs to reduce the rate of burns.

These applications contribute to improving the survivability of firefighters and soldiers under high-intensity flame conditions.

Standards

EN ISO 11612:rotective clothing - Clothing to protect against heat and flame - Minimum performance requirements

EN ISO 11611:Protective clothing for use in welding and allied processes - Minimum basic safety requirements

ISO 13506:Protective clothing against heat and flame - Test method for complete garments - Prediction of burn injury using an instrumented manikin

EN469:2005:Protective clothing for firefighters - Performance requirements for protective clothing for firefighting

ISO13506-1:Protective clothing against heat and flame- part1: Test method for complete garments-Measurement of transferred energy using an instrumented manikin

ISO13506-2:Protective clothing against heat and flame- part2: Skin burn injury prediction- Calculation requirements and test cases

ASTM F1930:Standard test method for evaluation of flame-resistant clothing for protection against fire simulations using an instrumented manikin

GB8965.1:Protective clothing - Flame retardant protective clothing

Principle

The burning manikin system is composed of:

1. computer combustion dummy;

2. thermal sensor group;

3. flame generator;

4. computer control module;

5. data acquisition and processing module;

6. burn analysis module.

Features

High-precision measurement: Utilizing 124 thermal sensors, it accurately measures changes in human skin temperature to predict burn severity.

Repeatability: Test results can be repeated in simulated fire environments, ensuring accuracy and reliability.

Rapid testing: The system can complete tests quickly, suitable for rapid assessment and quality control.

Versatility: Applicable to various types of protective clothing, such as flame-retardant suits and fire-fighting suits, providing comprehensive thermal protection performance evaluation.

Standardized testing: Complies with international standards such as ISO 13506 and ASTM F1930. ensuring international recognition of test results.

These features make the burning mannequin system of significant value in the field of safety protection, effectively improving the thermal protection performance of protective clothing and ensuring personnel safety.

Parameters

| Parameter | Description |

| Dimensions (L×W×H) | 14m × 6m × ≥6m |

| Weight | 2000 kg |

| Thermal Sensors | Monitor heat flux changes on mannequin surface; quantity varies by design |

| Combustion Flame Array | Multiple propane generators arranged around mannequin to simulate fire |

| Gas Supply System | Provides stable gas via high-pressure tanks and pipelines |

| Combustion Chamber | Houses flame array and mannequin for safe, controlled experiments |

| Data Acquisition System | Collects data from thermal sensors with processing units and cables |

| Testing Software | Controls experiments, analyzes data, and generates visual reports |

| Calibration Tools | Ensure accuracy and reliability of sensor data through calibration |

Send product request

Other supplier products

| Ethanol Resistance Tester | The Ethanol Resistance Tester is designed to evaluate the durability and chemical resistance of materials when exposed to ethanol under controlled ... | |

| Xenon Arc Chamber | 1. According to different specimens, xenon aging test chamber has a variety of models to choose from; For flat specimens, rotating drum type xenon ... | |

| In-situ expansion analysis system | The In-situ Expansion Analysis System is designed for high-precision measurement of dimensional and volumetric changes in electrochemical cells and... | |

| Hydraulic Oil Precision Filter Tester | 1. Applications The hydraulic oil filtration unit is designed to purify and maintain the cleanliness of hydraulic and lubrication systems across v... | |

| Gravel Resistant Impact Tester/Stone chip tester | The Gravel Resistant Impact Tester/Stone Chip Tester T201 is specifically designed for gravel impact testing of automotive materials and surface co... |

Same products

| Air Intake Filter Test System | Seller: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

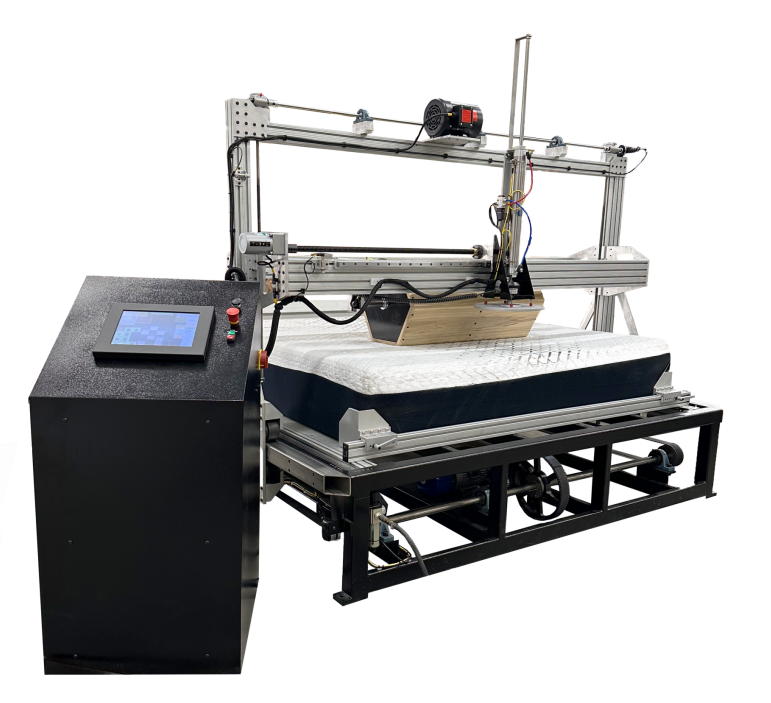

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Seller: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Seller: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

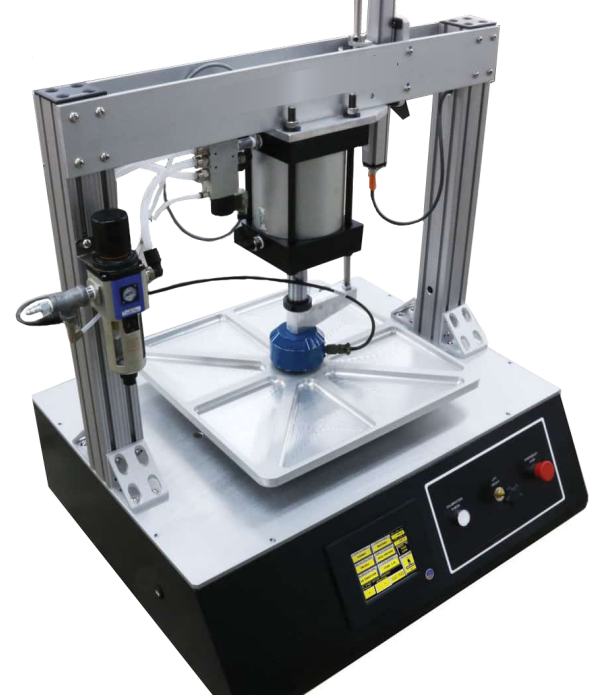

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

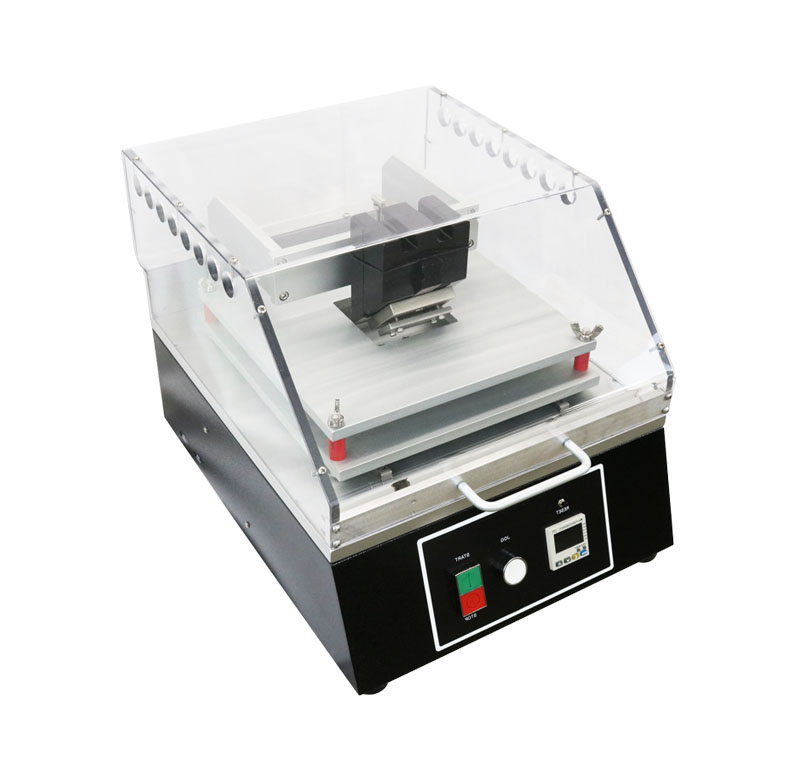

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Seller: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |