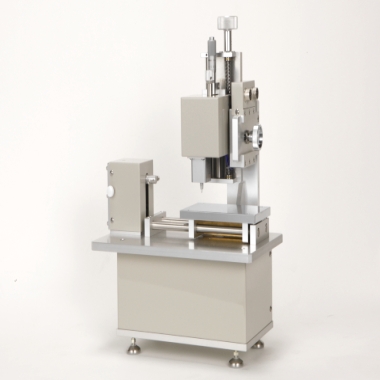

Spring Testers and Testing Machines

The Spring Tension and Compression Testing Machine is designed to accurately evaluate the tensile and compressive deformation, as well as the load characteristics of springs and other elastic devices. With precise control of load, deformation, and displacement, the instrument ensures high-precision measurements. It is suitable for testing springs, rubber components, reeds, and other elastic elements under specified working lengths, providing critical data for quality control, research, and development.

Application

(1) Testing tensile and compressive characteristics of metal springs.

(2) Measuring the deformation and load properties of rubber components.

(3) Evaluating reed and other elastic device performance.

(4) Quality control in spring manufacturing.

(5) Verification of spring performance in automotive suspension systems.

(6) Aerospace component testing to ensure resistance to extreme forces.

(7) Medical device spring testing to meet safety and performance standards.

(8) Product development and design optimization for elastic devices.

(9) Ensuring consistent spring performance in mass production.

Standards

(1) ISO 10243 – Metallic springs – Spring testing methods.

(2) EN 13597 – Springs – Determination of tensile and compression properties.

(3) JB/T 7796-1995, JB/T 7796-2005 – Spring tensile testing machine test methods.

(4) GB/T 13634 – Calibration of dynamometers for testing machines.

(5) JIS B7738-1993 – Spiral spring pressure and tension testing machine.

Features

(1) Accurate Measurement: High-precision force and displacement measurement.

(2) Versatile Force Range: Supports 1%–100% of full scale.

(3) Adjustable Test Speed: 0.5–500 mm/min to accommodate various spring types.

(4) Comprehensive Displacement Control: 170 mm stroke for standard spring sizes.

(5) Multi-Unit Measurement: Supports N, kgf, lbf, and ozf.

(6) Quality Assurance: Enables rigorous testing for production quality control.

(7) Design Support: Provides critical data for R&D and product optimization.

(8) Wide Industry Application: Suitable for automotive, aerospace, medical, and general industrial springs.

Parameters

| Parameter | Specification |

|---|---|

| Force measurement range | 1%–100% FS |

| Test speed | 0.5–500 mm/min |

| Displacement stroke | 170 mm |

| Spring free length | 170 mm |

| Disc diameter | 50 mm |

| Measurement units | N, kgf, lbf, ozf |

| Power supply | AC 220V ±10%, 50Hz |

| Operating temperature | 20 ±10℃ |

| Transport temperature | -27℃ to +70℃ |

Accessories

(1) Host machine

(2) Load cells and fixtures

(3) Clamps for tensile and compression testing

(4) Control panel and display interface

(5) Power supply cable

(6) User manual

Test Procedures

(1) Install the spring or elastic component securely in the appropriate fixture.

(2) Select the measurement mode (tension or compression) and set the test parameters, including load range, displacement, and speed.

(3) Start the test; the machine will apply load and record deformation and force data automatically.

(4) Monitor the measurement display during testing to ensure correct operation.

(5) After completion, stop the machine and remove the tested component carefully.

(6) Record test results and compare with specifications to evaluate spring performance.

(7) Repeat testing if multiple samples or different load conditions are required.

Maintenance Information

(1) Regularly inspect fixtures, load cells, and moving components for wear or damage.

(2) Lubricate guide rails and mechanical parts as recommended by the manufacturer.

(3) Clean the testing area and components after each test to remove debris.

(4) Check electrical connections and control systems periodically to ensure safety.

(5) Store the machine in a clean, dry environment when not in use.

(6) Follow operational safety procedures to prevent injury during testing.

Send product request

Other supplier products

| Resistance Tester for Molten Metal Droplet (Splash) Impact Performance | Performance and Standards: This resistance tester for molten metal droplet (splash) impact performance is developed in accordance with testing sta... | |

| Automatic voltage internal resistance tester | The Automatic Voltage & Internal Resistance Tester is a precision electrical testing instrument designed for rapid and accurate measurement of ... | |

| Guidewire Pushing Force Tester | The Guidewire Pushing Force Tester is a testing device used to verify and record the performance characteristics of interventional medical devices ... | |

| Particle Wear Testing Machine (for Particle Abrasion Tester) | The Q-4D particle wear tester is specially designed as a standard instrument based on the national standard "Method for Determination of Wear Rate ... | |

| Rubber non-rotor vulcanization Tester | The Rubber Non-Rotor Vulcanization Tester is a precision instrument designed for the rubber processing industry to monitor and control rubber mater... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |