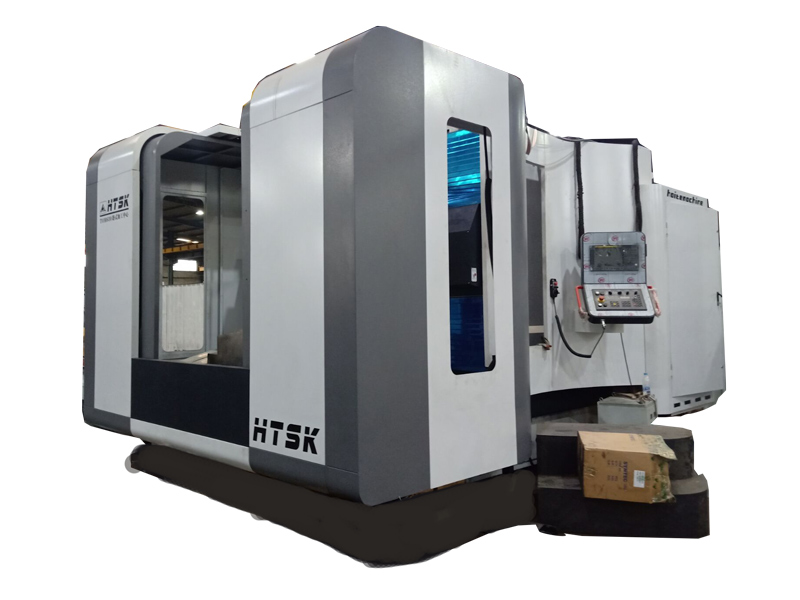

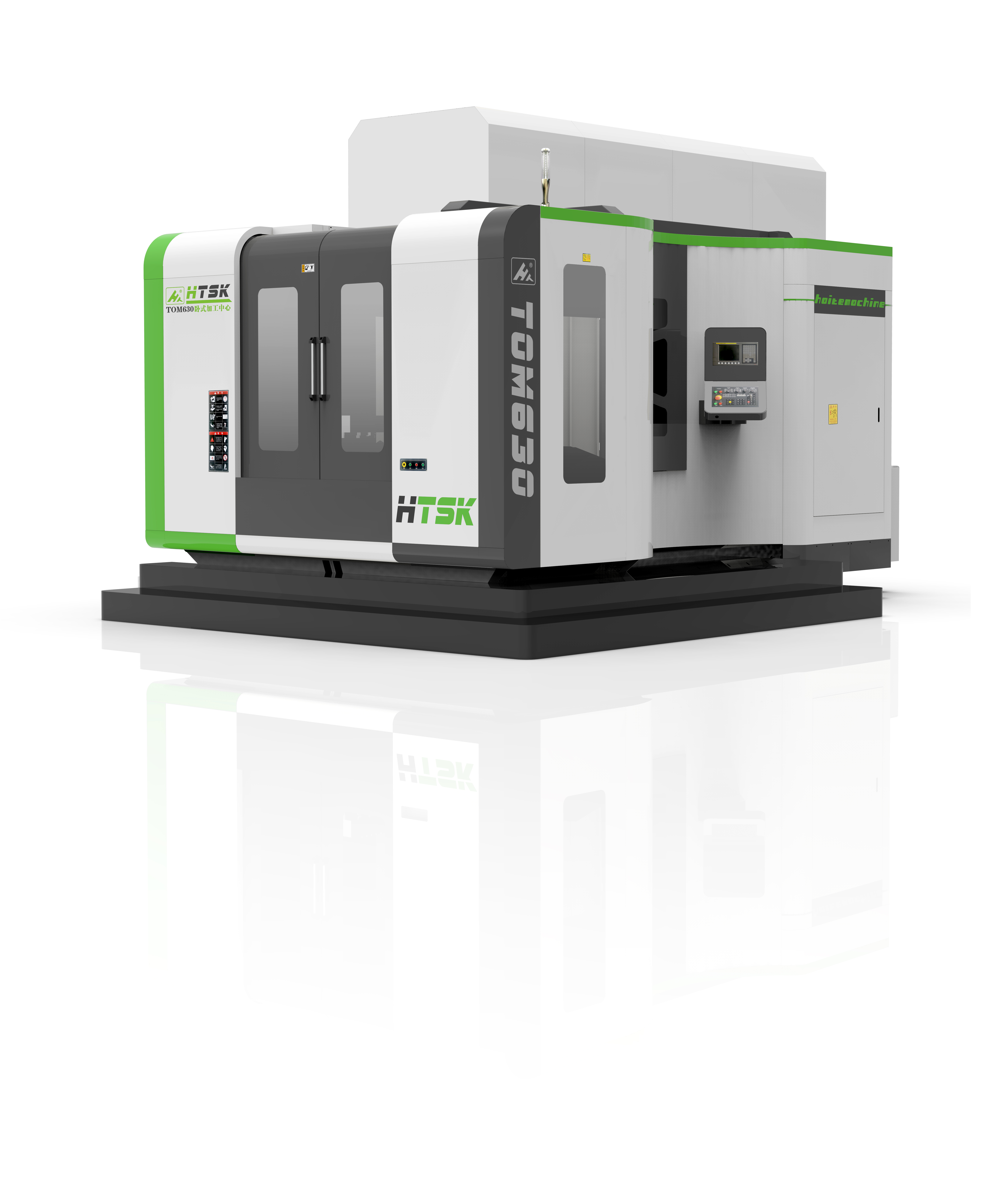

TOM1000 Horizontal Machining Center

- Standard configuration of machine tools

- Structure of machine tool

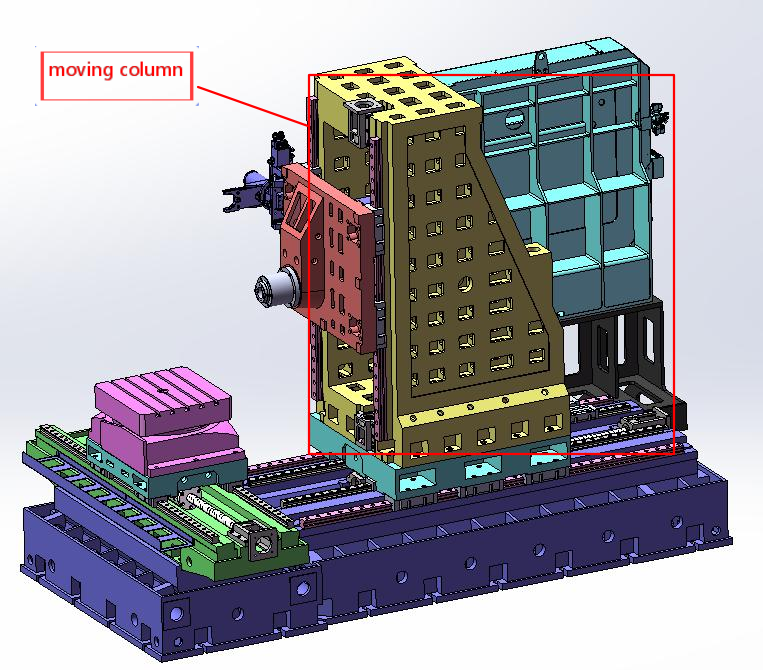

The inverted "T" structureis adopted. It is a regular reinforced horizontal machining center structure, and the vertical column is a moving column structure sliding left and right. The table slides forward and backward. This structure has the advantages of high precision, strong rigidity and long life.

- The base of the machine, column, spindle box, rotary table and other basic parts are all made of high-strength lost mold casting technology, and the internal metallographic organization is stable to ensure the high stability of the basic parts.1.3. high rigidity, high precision spindle

(1) the spindle motor is driven by the high-torque toothed synchronous belt, which does not slip and can greatly reduce the transmission noise and heat generation.(2) the spindle adopts the precision NSK bearing of Japan, with high speed and high precision, which can be heavily cut.(3) the spindle box adopts 1:1 nitrogen balance balance, which is more reliable, stable, high-speed and noiseless. Make the spindle in high speed operation, avoid resonance phenomenon, to ensure the best machining accuracy.

- Adopt Taiwan LTM C3 high precision, high strength ball screw. Using imported high-precision lock nut, ball screw after pre-stretching, greatly increase the transmission rigidity and eliminate the impact of thermal deformation caused by the movement, thus ensuring the positioning accuracy and repeated positioning accuracy of the machine tool.

- X, Y, Z axis adopts the original Taiwan HIWINroller heavy duty guide rail, the line rail slide seat is widened and enlarged processing, especially the Z axis slide seat. Heavy-duty roller rail can meet the requirements of high speed and high precision of customers, but also can be strong cutting, but also increase the service life of machine tool rails and other characteristics.

- The machine is equipped with sealed guide rail protection cover, effectively protect guide rail and lead screw, prolong its service life.

- When the machine is equipped with three-dimensional full protection, the machine is guaranteed not to vibrate when strong chip cutting. Exterior protection adopts side operating system position. Convenient for customers to operate and greatly protect the safety of the operator. The exterior protection is controlled by four doors. The front part is designed to open the door, which is convenient for customers to change the workpiece quickly. The front part of the hair protection and the operation position contain two anti-skid pedal design, which greatly improves the operation of the equipment.

- The front of the machining center is designed with double control buttons, including emergency stop button control to improve the safety of the operator, including the cycle start and stop button to facilitate the operator to operate quickly and efficiently to reduce the labor intensity of the operation, including the water gun switch button to facilitate the rapid cleaning of the workpiece to ensure the workpiece finish.

- Equipped with Taiwan Shengjie chain knife library, this knife library is Taiwan original imported first-line brand knife library, knife library capacity is 24pieces.

- The position of the knife storehouse is fully enclosed built-in knife storehouse. When the knife needs to be changed, the knife storehouse will be opened automatically and quickly for rapid tool change, and the knife storehouse will be closed quickly after the tool change. The design of the fully enclosed knife storehouse improves the service life of the knife storehouse and the tool

- Numerical control system USESJapan FANUCcontrol system, The control system has the advantages of high stability, high speed, smooth surface and high precision. It has the function and machining ability of the manufacturing mold.

- Equipped with control oil circuit system: adopting the original active hydraulic oil supply system: we directly controlled by the operating system, automatic assignment of oil supply, according to the sports demand precise control oil supply parts with oil, greatly reduces the waste lubricating oil and avoid the pollution due to oil cooling fluid, greatly extended the use of coolant length and guarantee the balance of the oil and lubrication.

- High precision pitch compensation, each drive shaft adopts high precision laser laser detection and optimization compensation to make the positioning accuracy of each shaft more accurate, more suitable for processing high precision parts. At the same time, the advanced ball instrument is used to optimize the analysis and processing, to ensure the precision of the machine tool in the process of circle and surface.

- Main technical parameters of machine

|

Name |

Project |

Parameter |

|

Table |

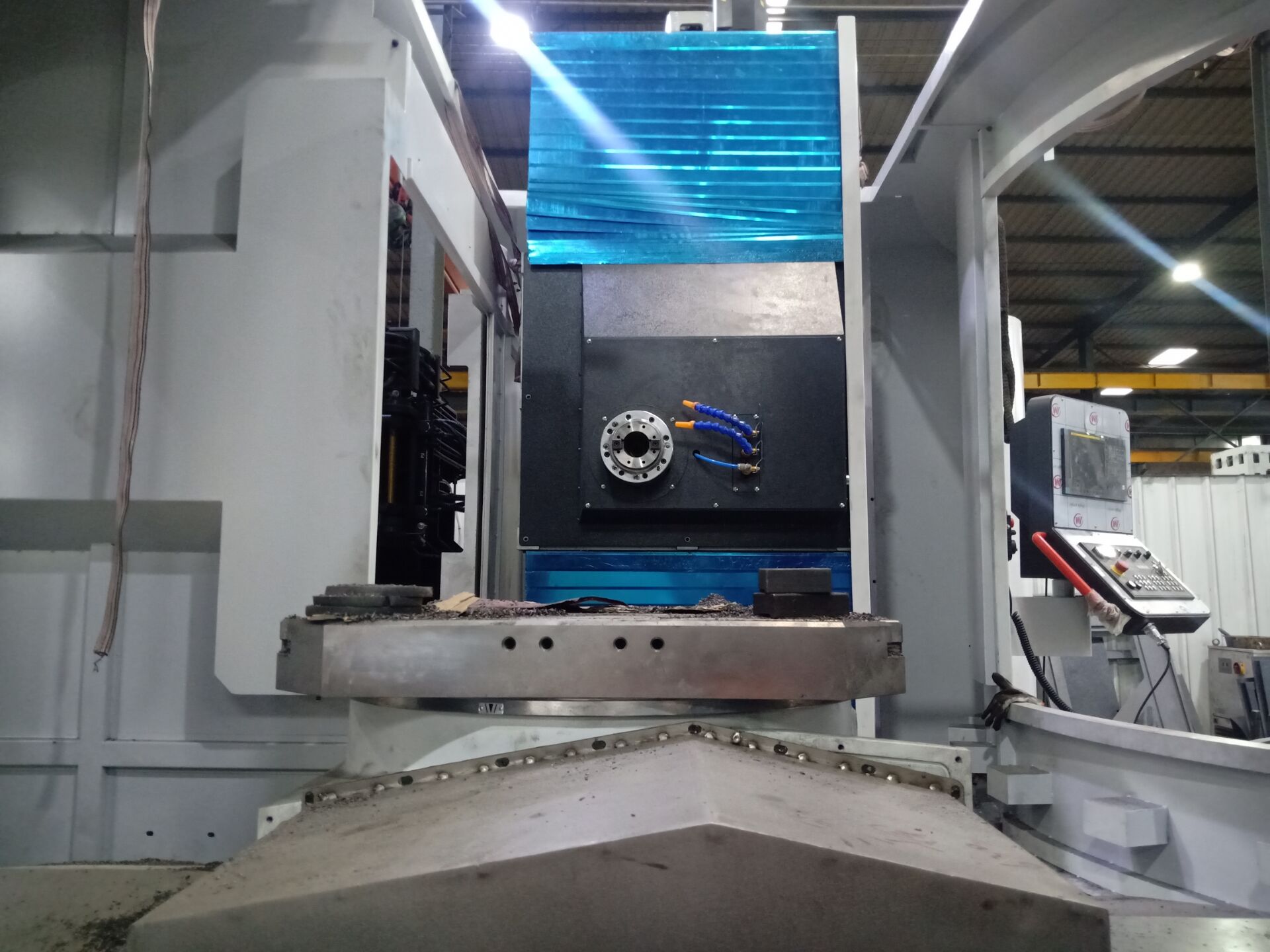

NC rotary table |

NRT-1000H |

|

Table size |

1000*1000mm |

|

|

5000kg |

||

|

T slot qty-width |

7-22mm |

|

|

Spindle |

Spindle speed |

50~6000 mm/min (Maximum 1500RPM after speed change of gearbox) |

|

Distance spindle axis to table |

0-1470mm |

|

|

Spindle nose to table surface |

300-1650mm |

|

|

Spindle taper |

BT50-190mm |

|

|

Motor |

Spindle motor |

15/18.5KW Rated torque 143NM, S1 torque 236NM (944NM after gearbox change) High torque wide area motor |

|

Spindle reducer changes speed |

1:4 automatic switch between two gears |

|

|

X and Y servo motors |

βiS30/2000 The Y-axis contains a clutch brake |

|

|

Z servo motor |

βiS40/2000 |

|

|

B servo motor |

ΒiS22/3000 |

|

|

Box way |

X axis travel |

2000mm |

|

Y axis travel |

1400mm |

|

|

Z axis travel |

1350mm |

|

|

X/Y axis rapid feed |

20m/min |

|

|

Z axis rapid feed |

12m/min |

|

|

Cutting feed speed |

0-6000mm/min |

|

|

X roller heavy duty line rail |

2*65mm Roller overloadingtype |

|

|

Yroller heavy duty line rail |

2*65mmRoller overloadingtype1*55mm Roll ball type |

|

|

Zroller heavy duty line rail |

2*65mm Roller overloadingtype 2*65mm Roll ball type |

|

|

Automatic tool changer |

Tool changer type |

Disc type |

|

Standard tool number |

24pcs |

|

|

Maximum tool diameter |

full tool Φ 120mm |

|

|

Cooling system |

Spindle workpiece cooling system |

Spindle ring spray function |

|

Coolant Through Spindle Center(CTS) with 20kg |

||

|

Two water and one gas |

||

|

Body cooler |

Environment-friendly fully sealed water tank |

|

|

Capacity of 180 l |

||

|

CNC system |

FANUC OiMF 1 plus |

|

|

Program prefetch function |

||

|

Support four axis four linkage function |

||

|

Bell-shaped acceleration and deceleration before interpolation |

||

|

High speed and high precision function |

||

|

β series drive motor |

||

|

Chip conveyor |

Automatic chip removal unit |

There are 4 screw chip removal machines in the body |

|

Transverse 1 chain chip extractor |

||

|

Crawler chain structure in water tank |

||

|

Large capacity chip car |

||

|

Accuracy |

Indexing angle |

1° |

|

Indexing accuracy |

10″ |

|

|

Accuracy of repeated indexing |

2″ |

|

|

X/Y/Z positioning accuracy |

300mm/±0.0075mm |

|

|

X/Y/Z accuracy of repeated positioning |

300mm/±0.005 mm |

|

|

Weight and Size |

Net Weight |

32000kg |

|

Overall Dimension |

6600*6200*4200mm |

- List of Standard configuration

|

Name |

Name |

||

|

1 |

Work-piece cooling system (two water and one gas) |

8 |

Rigid tapping |

|

2 |

24V safety working lamp |

9 |

Rs-232 interface and DNC function |

|

3 |

X/Y/Z guide rail stainless steel shield |

10 |

Anchor bolt and pad |

|

4 |

Simple oil water separator |

11 |

Electrical box cooling system |

|

5 |

Holding a gun |

12 |

Safety lock of distribution box |

|

6 |

Automatic lubrication system |

13 |

Double helix type chip cleaner |

|

7 |

LED red, yellow and green warning lights |

- List of main accessories and selected brands

|

Project |

Quantity |

Name of manufacturer |

|

|

1 |

FANUC Oi MF 1 Plus |

1 set |

FANUC |

|

2 |

NC rotary table |

1 set |

PARKSON |

|

3 |

Spindle servo motor and driver |

1 set |

FANUC |

|

4 |

X, Y, Z ,B servo motor |

Each 1 set |

FANUC |

|

5 |

X, Y, Z, Bdrives |

Each 1 set |

FANUC |

|

6 |

X, Y, Z axis screw bearing With lock nut |

Each 1 set |

JAP NSK |

|

7 |

X, Y, Z axis ball screw φ63mm*12mm |

Each 1 set |

TAIWAN LTM |

|

8 |

X axis roller heavy rail 55mmZ and Y axis roller heavy duty guide rail 65mm |

Each 1 set |

TAIWAN HIWIN |

|

9 |

hydraulic pressure station |

||

|

10 |

Spindle unit |

1 set |

TAIWAN KENTURN |

|

11 |

|||

|

12 |

Main pneumatic components |

1 set |

Air TAC |

|

13 |

Main electrical components |

1 set |

FRANCE SCHNEIDER |

|

14 |

A knife cylinder |

1 set |

CHANGZHOU GUODING |

|

15 |

Synchronous belt wheel and synchronous belt |

1 set |

With Taiwan spindle matching |

|

16 |

Cutting fluid pump |

1 set |

JANYANG |

|

17 |

Automatic lubricating oil pump |

1 set |

|

|

18 |

Oil metering unit |

1 set |

|

|

19 |

Electrical cabinet cooling system |

1 set |

SHANGHAI |

|

20 |

Transformer |

1 set |

SHANGHAI |

|

21 |

Electronic hand wheel |

1 set |

JUTAI |

|

22 |

Internal screw-type chip cleaner |

1 set |

HAITE |

|

23 |

External Screw-type chip cleaner |

1 set |

HAITE |

|

24 |

Peripheral guardrail type footstep operation platform |

||

|

25 |

Disk manipulator tool library BT50-24 |

1 set |

TAIWAN SANTET |

|

26 |

Spindle center outlet rotary joint |

CHINA |

|

|

27 |

Spindle center water outlet auxiliary tank 20kg |

CHINA |

|

|

28 |

Spindle reduction box |

ITALIANBF |

Send product request

Other supplier products

| GMC4026 Double column Gantry Machining Center | 4026 Vertical Fixed Beam CNC Gantry Machining Centeris a machine, electrical, hydraulic and other advanced technology in one of the mechanical pro... | |

| VMC1260 4 axis vertical machining center | I. Main performance and characteristics This machine tool is our company introduces the international advanced technology, develops and produces th... | |

| TOM1000 Horizontal Machining Center | Standard configuration of machine tools Structure of machine tool The inverted "T" structureis adopted. It is a regular reinforced horizontal ma... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |