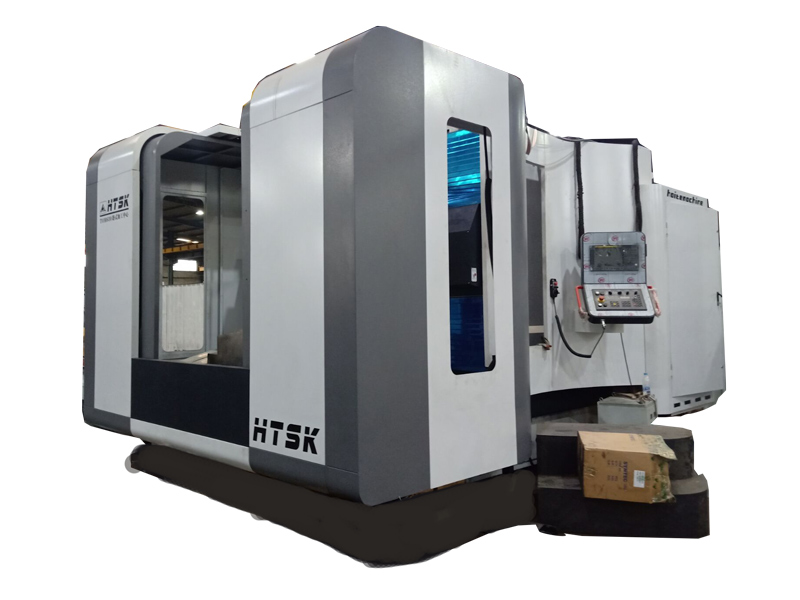

GMC4026 Double column Gantry Machining Center

- 4026 Vertical Fixed Beam CNC Gantry Machining Centeris a machine, electrical, hydraulic and other advanced technology in one of the mechanical processing equipment, mainly used for the processing of plane, surface and hole. Widely used in the mechanical manufacturing industry of various types of plate, box, frame and other complex parts rough, finishing, the machine can achieve vertical milling head transverse (Y axis), vertical movement (Z axis) and the table longitudinal movement (X axis) of the three axis linkage. It can be used for milling, boring, drilling, rigid tapping, reaming and counterboring.

- The machining center is Shandong HAITE CNCMachine Tool Co., LTD production of new equipment, complete with a high rigidity structure design, reliable precision stability and retention, complete facilities, parts design adopts modular, standardization degree is high, it has good compatibility, stable quality, advanced machine tool design, reliable performance, easy operation, easy maintenance. At the same time this machine tool is my company to introduce and absorb advanced European design and technology, the machine has a high rigid frame structure design, so not only has the strong cutting ability, but also can meet the processing of high precision parts.

- Gantry frame of machine

²The overall structure of the machine is a fully enclosed rigid frame structure consisting of a bed, double columns and fixed beams,the table moves longitudinally along the guide rail of the bed (X-axis),Fixed beam with a vertical high - power multi - function rammilling (boring) head,Milling boring head slide platemoves horizontally along the rail of the crossbeam (Y-axis)And the up and down movement in the pillow (Z axis).

- Basic parts of the machine

²The main base parts of the machine, such as the bed, the table, the column beam, the transverse slide plate, the milling head slide pillow, etc., are all made of high strength cast iron, resin sand modeling, with good shock absorption, thermal stability, high structural strength and rigidity of the whole machine.

- Ram milling head

²Vertical pillow milling head adopts ball screw direct drive design mechanism, driven by ac servo motor, boring and milling head with automatic loosening knife device, air-hydraulic compound loosening, disc spring tension.

- Z-axis motion nitrogen balance

²In order to reduce the no-load torque of ball screw, reduce the wear of ball screw and maintain the precision and stability of ball screw, nitrogen balanced cylinder is used to balance the unbalance force of the movement of Z axis up and down. This action is controlled by a separate pneumatic system.

- Guide rail type

²The X axis adopts4heavy duty (pin roller) straight line rail structure, the bed is cast as a whole, the structure is rigid.

²The Y axis adopts3heavy-duty (pin roller) straight rail structure, which is purchased into the form of 90°, which improves the precision and rigidity of the Y axis guide.

²The Z axis adopts the structure of moment type slide pillow, which is combined with the transverse slide plate.

²Each movement pair runs steadily, accurately, withstands wear and tear, and has a long life.

- X, Y, Z axis motion

²X, Y, Z axis are high precision preloaded ball screw.

²X and Y axes are connected directly by high-power ac servo motor, with no gap drive.

²X and Y axes are connected directly by high-power ac servo motor, with no gap drive.

- Automatic lubrication system

²Lubrication of each axis guide adopts the central integrated self-timing and quantitative lubrication system, which is automatic lubrication, loss of pressure and lack of oil security protection and alarm.

- Machine protection

²The X-axis guide rail of the machine tool is protected by a stainless steel telescopic cover.

²The Y-axis guide rail of the machine tool is protected by a telescopic organ cover.

²The gantry frame is provided with a ladder and protective railing for maintenance.

²The X, Y and Z axes adopt the protective device of towing chain。

²The outer protection adopts three-dimensional protection, with standard steel plates all made of 2mm to ensure the safety of the machine.

- Cooling System

²Spindle oil cooler

²Workpiece cooling system, two water one gas.

²Electrical cabinet cooling system, Built-in air conditioning in electrical cabinet.

²Looney airframe cooling box environment-friendly fully sealed water tank.

- Hydraulic pressure system

²Functions of the hydraulic system include spindle automatic release cutter, ram balancing cylinder, etc. The system adopts integrated installation to ensure the reliability of the whole machine movement and convenient maintenance.

- Balanced system

²Z axis adopts advanced nitrogen balance cylinder system, stable and reliable.

- Chip conveyor

²Both sides of the machine table are equipped with a set of screw chip extractor,effectively improves the cleaning capacity of processing waste debris.

²With two small iron filings carts

- Machine main drive, feed drive configuration

²Machine main drive (Pillow milling boring head) is driven by AC spindle motor.

²Axis X, Y, and Z are driven by AC servo motors, while axis X, Y, and Z are driven by AC servo motors with absolute encoders.

²Z axis with lock brake protection device, automatic clamping when power failure, can prevent pillow boring and milling head "slide" "slip car"

- System operating box

²The system operating box adopts suspension type, allowing users to move left and right. The system features a handheld electronic handwheel for easy operation and a safety interlock to ensure safety and reliability.

- CNC system

²The CNC control system adopts Japan FANUC Oi MF1 plus Systemabsolute value operation CNC system.The systemwith high-speed and high-precision function and supports 5 axis position and 4 axis continuousfunction. Each axis adopts Japan Fanuc αseriesabsolute value encoder and motor, which ensures the control system has the advantages of high stability, fast speed, smooth surface and high precision, and has the functions and machining capabilities due to mold manufacturing.

²Electric control auxiliary device:Fully enclosed constant temperature electric cabinet, standard protection, sealed dust, electric box equipped with lighting. (Circuit, oil circuit and machine tool soft connection)

- Automatic 90 degree angle milling head ²

²Equipped with automatic grabbing head and automatic door opening head library, it can automatically grab, automatically divide and realize automatic five sided processing.

- X/Y/Z axis liner scale

²Weaken the influence of machine temperature change on machining accuracy and improve accuracy stability.

- The operating environment of the machine

²Power supply: three-phase AC voltage 380V±10%, frequency 50HZ±1%

²Ambient temperature: 26°C±1°

²Relative humidity: ≤85%

- Implementation of reference standards

²The product complies with safety standards: GB 15760-2004 general technical conditions for safety protection of metal cutting machine tools and GB 5226.1-2008 Mechanical and electrical safety Mechanical and electrical equipment -- Part 1: General technical conditions;Its quality accuracy implementation standard "GB/T19362.1-2003 Gantry milling machine inspection conditions accuracy inspection part 1 fixed gantry milling machine".The product design, production, manufacturing, delivery process implementation standard GB/T 24001-2016 Environmental management System Requirements and Use Guide.

III.Main technical parameters

|

GMC4026Double column gantry machining center |

Specification |

|

|

Work Table |

Table size(W x L) |

4200x2200mm |

|

Max Weight Table |

18000kg |

|

|

Table T slot |

9-22x250mm |

|

|

Working area |

X-axis travel |

4200mm |

|

Y-axis travel |

2800 mm |

|

|

Z-axis travel |

1300mm |

|

|

Maximum width between two columns |

2600mm |

|

|

Spindle nose to table |

150-1450mm |

|

|

X/Y/Z axis guide rail |

X axis Pin-roller sliding block linear guide rail |

φ55mm * 3 line P grade |

|

Y axis Pin-roller sliding block linear guide rail |

φ55mm * 4 line P grade |

|

|

Z axis hard guide rail |

Using rectangular ram structure guide rail sticking plastic |

|

|

X/Y/Z axis leading screw |

X axis screw diameter |

Φ80mm * 12mm |

|

Y axis screw diameter |

Φ63mm * 12mm |

|

|

Z axis screw diameter |

Φ55mm * 10mm |

|

|

Spindle |

Spindle taper |

BT50 |

|

Connectedtype |

Gearbox and belt |

|

|

Spindle diameter |

BT50-190mm |

|

|

Driving Mode |

Gear-belt-driven |

|

|

Speed of spindle |

50-6000r/min |

|

|

Servo motor |

||

|

X/Y/Z axis Feed drive |

X/Y/Z axis cutting speed |

1~6000 mm/min |

|

X/Y/Z axis rapid feed speed |

12/14/12m/min |

|

|

X-axis servo motor |

αiF30/4000 7Kw 30/83N.m |

|

|

Y-axis servo motor |

αiF30/4000 7Kw 30/83N.m |

|

|

Z-axis servo motor |

αiF40/3000 6Kw 38/130N.m |

|

|

Numerical control system |

FANUC Oi-MF1 PLUS |

Diamond acceleration and deceleration before interpolationHigh speed and high precision function Processing preparation kitSupport four axis four linkage function |

|

Accuracy |

Repeated positioning accuracy |

500mm/+0.005mm |

|

Positional accuracy |

500mm/+0.0075mm |

|

|

Automatic tool change system |

Disctype toollibrary |

BT-50 |

|

Tool magazine capacity |

24T (Other specifications are optional) |

|

|

Other |

Z-direction balance weight |

Nitrogen balance system |

|

peculiar setup |

Cross beam maintenance platform |

|

|

Use source gas pressure |

||

|

Machine outline size |

12000x5200x5200mm(L×W×H) |

|

|

Machine weight |

54000 kg(about) |

|

- technical parameters

|

Automatic 90 degree milling head |

SPEC |

Note |

|

SpindleNumber |

1 |

|

|

Spindletaper |

BT50 |

|

|

Pull nail specification |

P50T-Ⅰ-MAS403 |

|

|

800rpm |

||

|

Installation method |

Automatic |

|

|

Tool clamping mode |

Automatic |

|

|

Milling head indexing positioning |

Graduation,5° |

|

|

Spindle radial runout near output spindle end |

≤0.005mm |

|

|

The radial runout distance of the main shaft is 300mm from the output main shaft end |

≤0.02mm |

|

|

Axial movement of milling head spindle |

≤0.008m |

|

|

Operating ambient temperature |

-5℃~40℃ |

|

|

Maximum air relative humidity |

60% |

- Partand Manufacturer

- ProjectQuantity Name of manufacturer

|

1 |

Numerical control system |

1 set |

FANUC |

|

2 |

Spindle servomotorand driver |

1 set |

FANUC |

|

3 |

X/Y/Z servo motor |

Each 1 set |

FANUC |

|

4 |

X/Y/Z drives |

Each 1 set |

FANUC |

|

5 |

Automatic 90° milling head |

1 set |

Chenhao |

|

6 |

X/Y/Z axis liner scale |

Each 1 set |

Heidenhain |

|

7 |

Gear box |

1 set |

ItalianBF |

|

8 |

X/Y/Z axis screw bearing |

Each1 set |

JAP NSK |

|

9 |

X/Y/Z axis ball screw |

Each1 set |

TAIWAN LSK |

|

10 |

X and Y axis pin-rollerrailguideline |

Each1 set |

TAIWAN HIWIN |

|

11 |

Z-axis hard rail paste plastic |

Each 1 set |

American fluorin resin |

|

12 |

SpindleunitPowerful spindle |

1 set |

TAIWAN KENTURN |

|

13 |

Main pneumatic components |

1 set |

AirTAC |

|

14 |

Main electrical components |

1 set |

SCHNEIDER |

|

15 |

Cutting fluid pump |

1 set |

TAIWAM STAHL |

|

16 |

A knife cylinder |

1 set |

CHANGZHOU GUODING |

|

17 |

Lock nut |

Each1 set |

TAIWAN NSK |

|

18 |

Automatic lubricating oil pump |

1 set |

|

|

19 |

Electrical cabinet cooling system |

1 set |

SHANGHAI |

|

20 |

Transformer |

1 set |

SHANGHAI |

|

21 |

Electronic hand wheel |

1 set |

JUTAI |

|

22 |

Screw-type double chip cleaner (both sides) |

1 set |

HAITE |

|

23 |

Side chip extractor crawler(including chip car) |

1 set |

CHINA |

|

24 |

Disk Arm type ATC-24T |

1 set |

TAIWANSHENGJIE |

|

25 |

Spindle oil cooler |

1 set |

TONGFEI |

|

26 |

Oil skimmer(oil water separator) |

1 set |

HAITE |

|

Project |

Project |

||

|

1 |

Full protection (excluding top surface) |

10 |

Rs-232 interface and DNC function |

|

2 |

Work-piece cooling system (two water and one gas) |

11 |

Anchor bolt and pad |

|

3 |

24V safety working lamp |

12 |

Electrical box cooling system |

|

4 |

X/Y/Zguide rail stainless steel shield |

13 |

Full gear transmission |

|

5 |

oil water separator |

14 |

Liquid crystal display |

|

6 |

Hand-held jet gun |

15 |

Safety lock of distribution box |

|

7 |

Automatic lubrication system |

16 |

Z axis nitrogen balancing system |

|

8 |

LED red, yellow and green warning lights |

17 |

Screw-type double chip cleaner (both sides) |

|

9 |

Rigid tapping |

18 |

Centralized automatic lubrication system |

Send product request

Other supplier products

| TOM1000 Horizontal Machining Center | Standard configuration of machine tools Structure of machine tool The inverted "T" structureis adopted. It is a regular reinforced horizontal ma... | |

| VMC1260 4 axis vertical machining center | I. Main performance and characteristics This machine tool is our company introduces the international advanced technology, develops and produces th... | |

| GMC4026 Double column Gantry Machining Center | 4026 Vertical Fixed Beam CNC Gantry Machining Centeris a machine, electrical, hydraulic and other advanced technology in one of the mechanical pro... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |