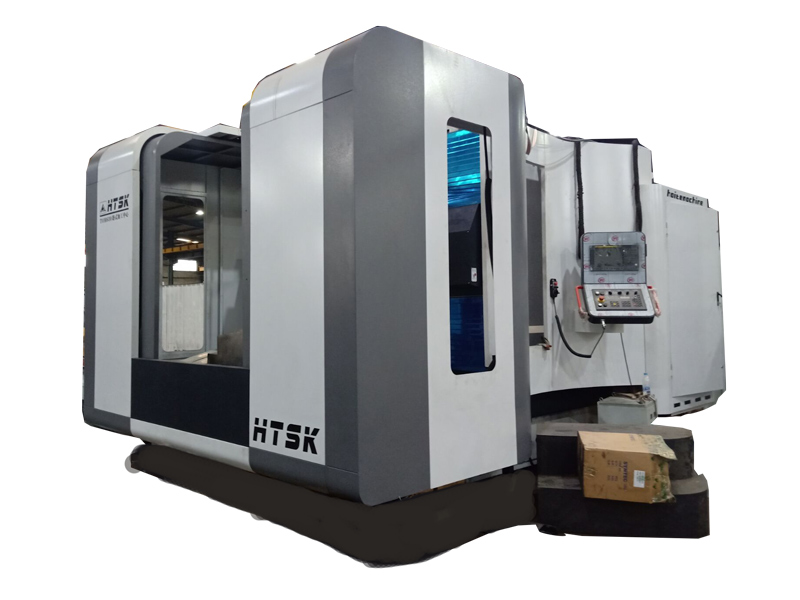

VMC1260 4 axis vertical machining center

I. Main performance and characteristics

This machine tool is our company introduces the international advanced technology, develops and produces the new generation numerical control machine tool, this machine tool is widely used in the military industry, the aerospace, the automobile, the mold, the medical equipment, the mechanical manufacture and so on profession box body part, the shell part, the disk shape part and so on processing.The machine is equipped with automatic lubrication system and cooling system, and adopts fully enclosed vertical protective cover.

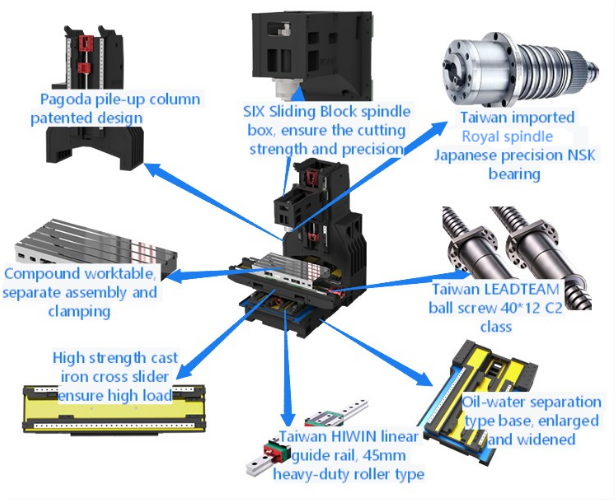

1, The base of the machine tool, column, spindle box, cross slide table, work table and other basic parts all adopt the unique formula of cast iron, make the cast iron reach the alloy cast iron of high strength, and adopt the resin sand casting molding technology, the internal metallographic structure is stable, ensure the high stability and durability of the basic parts.

2,"Pagoda accumulation structure"body

The main difference in appearance is that the column is "pagoda accumulation structure", but in order to cooperate with the structural support, the whole machine body has been redesigned to match and strengthen, than the traditional "people" structure. It has the following advantages.

A, The pagoda structure causes the machine base to be much wider than the traditional "man" structure. The wider the structure, the more stable it is, especially the effective resistance to vibration caused by cutting.

B,The XYZ axis of the pagoda structure has a much larger rail span. According to different models, the online rail specifications and the number of tracks are strengthened differentlyThe weight of the body is usually higher than the previous herringbone structure design, depending on the type, the weight has been increased between 2tons and 3.5 tons.

C,The pagoda structure can adopt the floor support structure to install the ATC, the use of a long time will not cause the influence of the ATC on the geometric accuracy of the body.

D,Because the body is heavy, the load is large, so the screw length of the ball screw of three axes is longer, the screw bearing of three axes is larger, and the number of bearings used by three axes is more. The three-axis motor also has more torque. Therefore, the traditional "people" structure of the machine tool, feed quantity and feed speed greatlyimprove the efficiency can be increased by about 30%,

E,Machine tool body heavy, can offset the low frequency vibration machine tool spindle in high speed rotation, so it can effectively improve the processing efficiency, product accuracy, especially the service life, than the traditional "people" structure can be extended by about 50%.

The product processing precision and finishing degree of improvement, as well as the improvement of the processing efficiency, can maximize for customers bring more effective competitiveness.

3, High rigidity, high precision spindle:TAIWAN KENTURNspindleBT40-150mm.

(1) Spindle motor is driven by toothed synchronous belt, which can greatly reduce transmission noise and heat generation.

(2) The spindle adopts precision grade Japanese NSK bearing, with high speed, high precision and the highest speed up to 10000r/min.

(3) The spindle box adopts 1:1 weight hammer to balance the balance weight, which is more reliable and stable.Make the spindle in high speed operation, avoid resonance phenomenon, ensure the best machining accuracy.

4, Using TaiwanLTMC3class high precision, high strength ball screw.Imported high-precision locking nut, ball screw after pre-stretching, greatly increase the transmission rigidity and eliminate the influence of thermal deformation caused by movement, thus ensuring the positioning accuracy and repeated positioning accuracy of the machine tool.

4,X axis USES FOUR 45mm roller heavy duty strong line rail,eightsliding seat design structure, can multiply the contact area between the line rail and sliding seat, and the work table USES a compound work table, in addition to increase the strength of the work table accident, and can minimize the sliding seat of the fixed bolt on the accuracy of the work table interference.5,Y axis adopts two 45mm wire rails, eight sliding seat design structure,two main bearing rails and two supporting rails. The two main bearing rails only guarantee the accuracy and load of the movement, while the two supporting rails only guarantee the supporting function. The unique installation process is adopted to overcome the influence of accumulated errors caused by the installation of multiple rails on the precision and service life of the rails.6,Z axis USES two 55mm roller heavy load strong line rail, sixsliding seat design structure, and increase and widen the sliding seat, is the contact area is larger, improve the overall rigidity of the Z axis.

7,The machine is equipped with sealed guide rail protective cover, effective protection guide rail and lead screw, extend its service life. When the machine with three-dimensional full protection, the machine in the strong chip to ensure that the vibration.(customers can choose the style according to their own requirements)

8,Oil system, equipped with system control: using our original active hydraulic oil supply system: directly controlled by the operating system, automatic assignment of oil supply, according to the sports demand precise control oil supply parts with oil, greatly reduces the waste lubricating oil and avoid the pollution due to oil cooling fluid, greatly extended the use of coolant length and guarantee the balance of the oil and lubrication

9,The wiring in the electrical cabinet conforms to the national electrical safety standards, ensuring that the control system is free from external interference during operation.Better ensure production safety.

10,High-precision pitch compensation. Each transmission shaft adopts high-precision laser beam for detection, optimization and compensation to make the positioning accuracy of each shaft more accurate and more suitable for machining high-precision parts.At the same time, the advanced ball club instrument is used to optimize the processing, to ensure the accuracy of the machine tool in the processing of circle and surface.

Z axis is equipped with lock brake protection device, which can be clamped automatically when power is cut off, which can prevent the boring and milling head of sliding pillow from "sliding".11,The CNC control system adopts Japan Mitsubishi M80B Systemabsolute value operation CNC system.The systemwith high-speed and high-precision function and supports 5 axis position and 4 axis continuousfunction.Each axis adopts JapanMitsubishi absolute value encoder and motor, which ensures the control system has the advantages of high stability, fast speed, smooth surface and high precision, and has the functions and machining capabilities due to mold manufacturing.

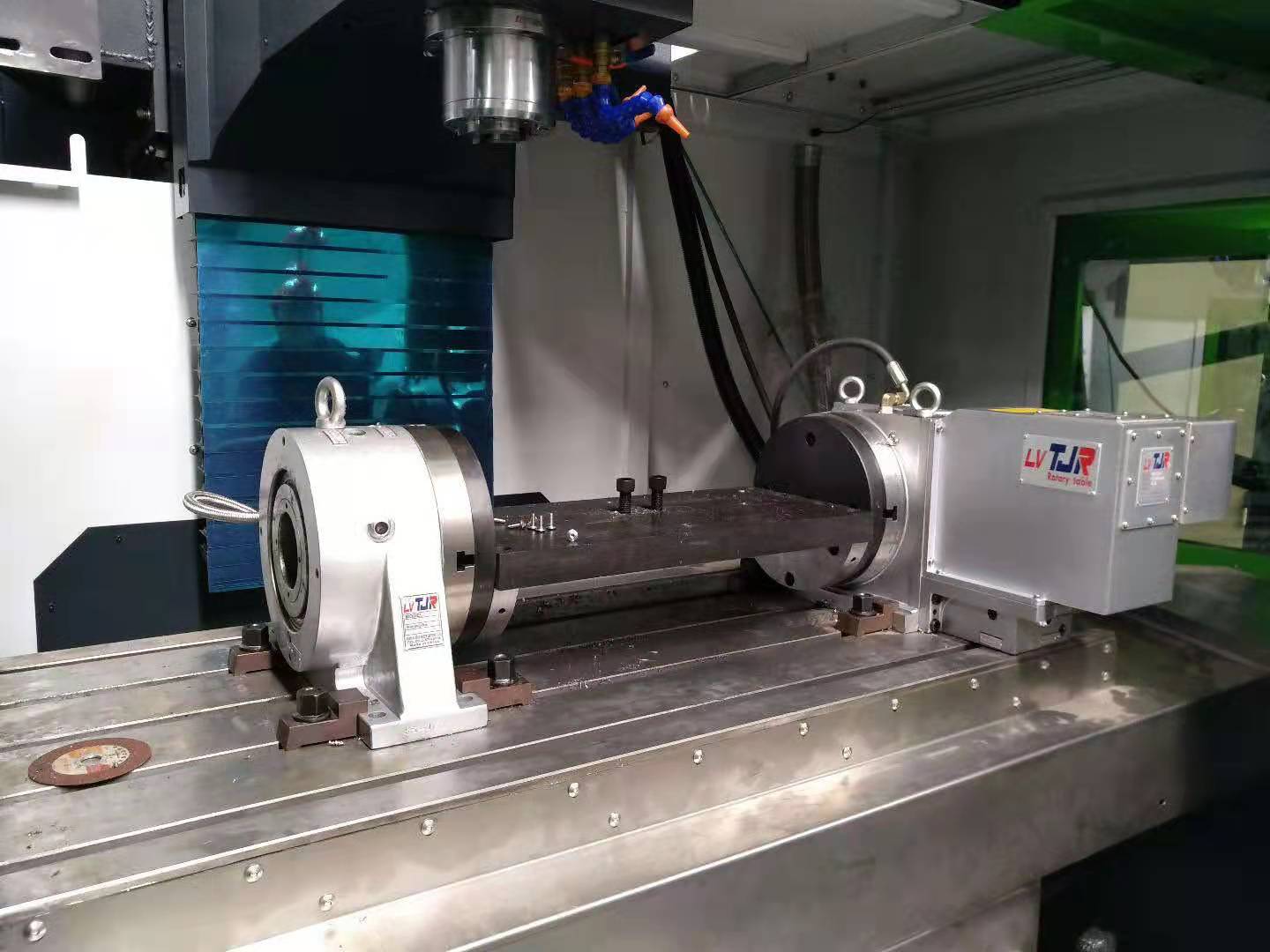

Equipped with Taiwan LVTJR 250 CNC rotary table, 250mm manual tailstockt, can rotate 360° in Y direction. Achieve the function of single loading card compound processing.

II. Main technical parameters

|

VMC1260Vertical machining center |

|

|

Worktable Capacity |

|

|

Table size |

1300mmx600mm |

|

1000kg |

|

|

T slot qty-width*distance |

5-18x120mm |

|

Travel |

|

|

X axis travel |

1200mm |

|

Y axis travel |

600mm |

|

Z axis travel |

650mm |

|

X/Y axis rapid feed |

30m/min |

|

Z axis rapid feed |

24m/min |

|

Cutting feed speed |

1-10000mm/min |

|

Spindle |

|

|

Spindle nose to table surface |

120-770mm |

|

Spindle center to Column surface |

675mm |

|

Spindle taper |

BT40-150mm |

|

Spindle speed |

50~10000 rpm Directdriven type |

|

Spindle motor power |

11/15KW |

|

X/Y/Z-axis |

|

|

X-axis line guide mode |

45mm*4roller heavy duty strong line rail fourslide seat |

|

X-axis servo connectionmode motor power and connectionmode |

3KWdirect connection |

|

Y-axis line guide mode |

45mm*2roller heavy duty strong line rail fourslide seat |

|

Y-axis servo connectionmode motor power and connectionmode |

3KWdirect connection |

|

Z-axis line guide mode |

55mm*2roller heavy duty strong line rail SIX slide seat |

|

Z-axis servo connectionmode motor power and connectionmode |

3KWdirect connection |

|

Automatic tool changer |

|

|

ATCtype |

Arm type ShengJie-ATC |

|

Standard tool number |

24pcs |

|

Tool change time |

(tool to tool) 2.2s |

|

Controller |

|

|

Numerical control system |

Mitsubishi M80B Program preview function Support four axis four linkage function High speed and high precision function |

|

Lubrication system |

Active lubrication system Brake distribution oil injection on demand It can monitor the oil filling status in real time |

|

Outer protective |

Fully enclosed environmental protection Waterproof, dustproof, noise proof and harmful gas proof |

|

The protective |

XY axis stainless steel expansion protection Large load bearing type with supporting pulley Z rear stainless steel armor structure protection Fully enclosed protection |

|

Accuracy |

|

|

Positioning accuracy |

300mm/±0.005mm |

|

Accuracy of repeated positioning |

300mm/±0.003mm |

|

Other |

|

|

Net Weight |

9000 kg |

|

Overall Dimension |

3350mm*2350mm*2650mm |

- List of 4thaxis Rotary table technical parameters

|

TypeName |

Specification |

|

|

1 |

CNC rotary table |

CNC250mm |

|

2 |

Dial diameter |

Φ250mm |

|

3 |

Manual tailstock |

Φ250mm |

|

4 |

Height of center |

160MM |

|

5 |

Through-hole diameter |

Φ40MM |

|

6 |

T-SLOT |

12MM |

|

7 |

Guide block |

18H7 |

|

8 |

gear ratio |

1:90 |

|

9 |

Dividing unit (degree) |

|

|

10 |

rotate speed |

|

|

11 |

Brake torque (air pressure) |

31kg-m |

|

12 |

accuracy of segmentation |

20" |

|

13 |

Repeat accuracy (unidirectional) |

4″ |

IV.List of main accessories and selected brands

|

Project |

Quantity |

Name of manufacturer |

|||

|

1 |

CNC system |

1 set |

Mitsubishi |

||

|

2 |

Spindle servo motor and driver |

1 set |

Mitsubishi |

||

|

3 |

X, Y, Z servo motor |

Each 1 set |

Mitsubishi |

||

|

4 |

X, Y, Z drives |

Each 1 set |

Mitsubishi |

||

|

5 |

X/Y/Z axis screw bearing P4 class 5/5/5 |

Each 1 set |

JAP NSK |

||

|

6 |

X/Y/Z axis ball screw C3class 40*12mm |

Each 1 set |

TAIWAN LTM |

||

|

7 |

X /Y/Z axis roller rail line 45mm/45mm/55mm |

Each 1 set |

TAIWAN HIWIN |

||

|

8 |

Spindle unit |

1 set |

TAIWAN KENTURN |

||

|

9 |

Main pneumatic components |

1 set |

Air TAC |

||

|

10 |

Main electrical components |

1 set |

FRANCE SCHNEIDER |

||

|

11 |

A knife cylinder |

1 set |

CHANGZHOU GUODING |

||

|

12 |

Lock nut |

Each 1 set |

TAIWAN NSK |

||

|

13 |

Cutting fluid pump |

1 set |

JANYANG |

||

|

14 |

X and Y guide rail protection (high speed to strengthen internal defense) |

1 set |

CHINA |

||

|

15 |

Z-axis organ housing (high speed internal protection) |

1 set |

CHINA |

||

|

16 |

Automatic lubricating oil pump |

1 set |

|||

|

17 |

Metering unit for oil route |

1 set |

|||

|

18 |

Electrical cabinet cooling system |

1 set |

SHANGHAI |

||

|

19 |

Transformer |

1 set |

ZUOJIN |

||

|

20 |

Electronic hand wheel |

1 set |

JUTAI |

||

|

21 |

Arm type ATC-24T |

1 set |

TAIWAN SANTET |

||

|

22 |

Screw chip-conveyor |

1 set |

Shandong Hite |

||

|

23 |

Oil chiller |

1 set |

Okada |

||

|

24 |

4th axis rotary table |

1 set |

TAIWAN LVTJR |

||

|

25 |

Manual tailstock |

1 set |

TAIWAN LVTJR |

||

Send product request

Other supplier products

| VMC1260 4 axis vertical machining center | I. Main performance and characteristics This machine tool is our company introduces the international advanced technology, develops and produces th... | |

| GMC4026 Double column Gantry Machining Center | 4026 Vertical Fixed Beam CNC Gantry Machining Centeris a machine, electrical, hydraulic and other advanced technology in one of the mechanical pro... | |

| TOM1000 Horizontal Machining Center | Standard configuration of machine tools Structure of machine tool The inverted "T" structureis adopted. It is a regular reinforced horizontal ma... |

Same products

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... | |

| Horizontal Lathe | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | As a professional horizontal lathe manufacturerand horizontal lathe factory, Sealion Machine Tool... | |

| Gantry Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | SEALION supplies Gantry Machining Center both tables moving type or gantry moving type. Gantry ty... |