CIP cleaning system

CIP cleaning system

Clean-in-place (CIP) is an automated method of cleaning the interior surfaces of pipes, vessels, equipment, filters and associated fittings, without major disassembly. CIP is commonly used for equipment such as piping, tanks, and fillers.

CIP employs turbulent flow through piping, and/or spray balls for large surfaces. In some cases, CIP can also be accomplished with fill, soak and agitate. The benefit to industries that use CIP is that the cleaning is faster, less labor-intensive and more repeatable, and poses less of a chemical exposure risk. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned. Simple, manually operated CIP systems can still be found in use today.

CIP cleaning system should formulate different cleaning and disinfection processes for different sites, and control them separately according to different CIP cleaning systems; design the CIP system on the basis of ensuring the effective operation of the CIP process, and at the same time, consider the flexibility of the system , economy and safety, environmental protection requirements, and reduce the chance of cross-contamination, etc. The cleaning of fermentation tanks should be based on normal temperature alkaline cleaning, which should be combined with regular pickling. During the design process of the CIP system, the factors that affect the normal operation of the system, such as: cavitation problem, liquid return filtration, circulation heating, etc., are all designed in order to make the CIP system more perfect.

Working Principle:

The CIP cleaning and disinfection system uses the dissolution of water, scouring and kicking, heat exchange, and the chemical action of cleaning agents and cleaning agents to remove pollutants on the inner walls of tanks, equipment, and pipelines. The working principle of the automatic CIP cleaning system is to control the opening and closing of the steam valve by measuring the temperature through the thermal resistance; to control the opening and closing of the water valve by measuring the level of the liquid level through the pressure transmitter; to measure the conductivity through the conductivity meter The size of the rate is used to control the opening and closing of the alkali and acid diaphragm valves. The overall control process is adding water and heating--alkali cleaning--hot water rinsing--acid cleaning--hot water rinsing.

Fully automatic CIP cleaning system consists of: acid tank, alkali tank, hot water tank, pure water tank, concentrated acid, concentrated alkali tank, heat exchanger, various pipes and pneumatic valves, pressure transmitter, conductivity meter, platinum thermal resistance and control systems.

Application:

CIP cleaning system is widely used in food and beverage production enterprises with a high degree of mechanization, such as food and beverage, pharmaceuticals, dairy products, fruit juice, fruit pulp, jam, wine, etc.

Send product request

Other supplier products

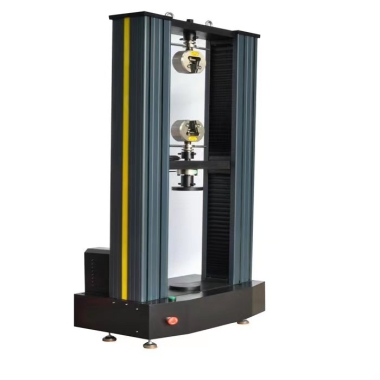

| Electronic geosynthetics comprehensive strength machine | Meet the standard GB/T16491-2022.GB/T15788-2017.GB/ T13763-2010. ASTM D4632M-a15.GB/ T2191. FZ/T01010. CJ/T452-2014. GB18173.1-2012 and JC/T2112.... | |

| (Ford) Automotive wire flexibility testing machine-QINSUN | Applicable standards: Engineering Specification-Ford Global Wire specificationPART NO. ES-AU5T-1A348-AA Scope of application: Suitable for wir... | |

| Digital Auto Burst Strength Tester-QINSUN | Digital Auto Burst Strength Tester Standards ASTM D3786. ERT 80-4-20. GB/T 7742.1. BS EN ISO 13938-1. BS 3424-6-B, ISO 3303-B, ISO 2758. ISO 3303... | |

| PTFE teflon rotary tank cleaning nozzle | PTFE tank cleaning nozzle Model NO.: STD series Working Principle: Using the force and reaction force of cleaning liquid to generate self-rotati... | |

| Fogging Tester | Standards DIN 75201: Automotive trim material fogging resistance. ISO 6452: Coated fabrics fogging behavior in vehicle interiors. SAE J1756: A... |

Same products

| Seat Bumping and Creep Test Bench | Seller: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Seller: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Seller: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Seller: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Seller: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |