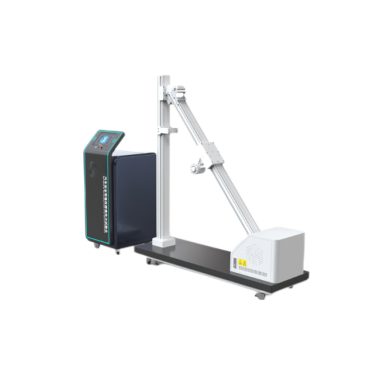

Wyzenbeek or Oscillatory Abrasion Tester

Product introduction:

Wyzenbeek wear resistance tester, also known as Oscillatory wear resistance tester, is used to test the wear resistance of fabrics against standard friction media or metal mesh surface friction movement, especially suitable for automotive decoration and furniture textile product. Instrument regulations American standard. There are 4 friction heads and electronic counter to control the running cycle.

Features:

Easy to control due to the precision electronic digital counter.

The protective cover provides protection and thus more safety.

Four abrasion heads to test samples simultaneously, thus greater efficiency.

Complied Standards:

ASTM D3597. ASTM D4157. CFFA-1A, FED-STD-191/5304. GM2756M, LP-463KB-06-01. LP-463KC-04-01. SAE J 948. SAE J1530. Toyota TSL 5101G 3.9.4 etc...

Working principles:

Install the long strip of sample fabric on the front and rear clamps of the friction head, and apply a certain tension force. Install the friction medium on the arc-shaped friction table to make the sample contact the friction medium and apply a certain load On the sample. The friction table swings back and forth to rub the sample, and after a certain number of frictions, evaluate the change in the breaking strength of the sample

![]() Standard configuration:

Standard configuration:

Main machine 1set

Imported rubber pad 8pcs/pack

Imported metal mesh 4pcs/pack

Imported standard abrasive No. 10 cotton canvas (60inches X 5yards)

Power cable 1pcs

Manual 1pcs

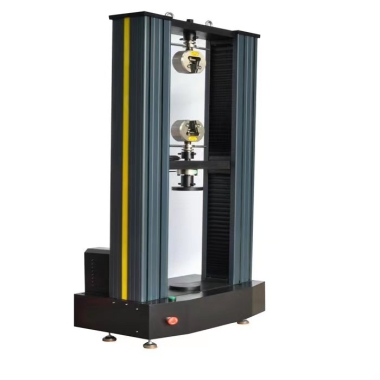

![]() Technical parameter:

Technical parameter:

1. Modern ergonomic design.

2. The suction device connected to the auxiliary vacuum cleaner.

3. Sealed transmission ensures quiet operation.

4. Test position: 4 heads.

5. Friction table: Curve surface-R100mm, length-400mm

6. Swing radian: 76+/-2mm.

7. Friction rate: 90+/-1/min(double friction).

8. Tension adjustment weight: 340g (tension adjustment range 8.9N-22.25N)

9. Load adjustment weight: 150g (load adjustment range 8.9N-17.8N)

10. Sample tension: 17.8N (adjustable)

11. Sample load: 13.4N (adjustable)

12. Sponge rubber pressure pad: 50X50mm(+/-1mm)

13. Instrument material: Stainless

14. Surface finishing: painting

15. Sample dimension: 245X73mm

16. Product dimension: 50X50X60 (LXWXH)

Send product request

Other supplier products

| Retractable pneumatic retractable tank washer machines | High impact 3D rotary tank washer Model number: STP-450 retractable rotary tank washer Working Principle: Impeller is driven by cleaning fluid a... | |

| Building material products single combustion tester | Product Information Single Burning Items(SBI), as a European evaluation of the fire-resistance performance of building materials, measures heat ... | |

| Rubbing Color Fastness Tester | Introduction Manual friction fastness tester is the most commonly used instrument for the textile industry to detect the color fastness of the... | |

| Seat Ingress/Egress Simulation Tester-QINSUN | Standard ISO 16840(Wheelchair Seating - Test Methods for Determining Mechanical Properties) FMVSS 207(Federal Motor Vehicle Safety Standard for... | |

| SDC Fading Grey Scale | Applicable Standards The SDC Grey Scale adheres to international colorfastness testing protocols, including: ISO 105-A02(Grey Scale for Asses... |

Same products

| Seat Bumping and Creep Test Bench | Seller: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Seller: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Seller: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Seller: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Seller: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |