Automotive wire cyclic bending testing machine

Standard

This testing machine aligns with global automotive industry standards for wire harness reliability, includingISO 6722(Road vehicles – Cables for conductor sets) andSAE J1128(Low-voltage battery cable specifications). By simulating repetitive bending stresses, it evaluates wire fatigue resistance under dynamic conditions, ensuring compliance with OEM specifications for in-vehicle wiring durability.

Product Advantages

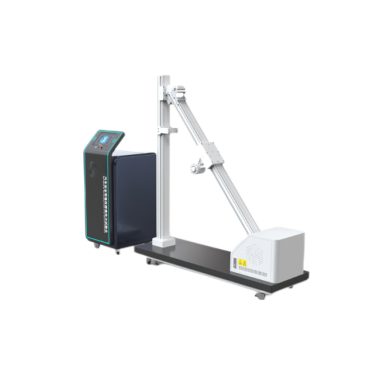

- Versatile Angle Adjustment: Swings up to 180° bi-directionally or any user-defined angle, accommodating sharp-bend (e.g., R3.75) and gradual-curve testing scenarios.

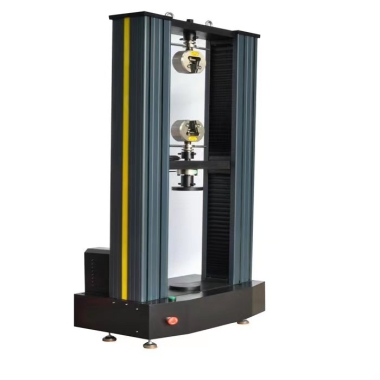

- Triple-Station Efficiency: Three independent test channels enable parallel testing of different wire specifications, tripling throughput compared to single-station machines.

- Precision Fatigue Analysis: ±1 cycle/min speed control and 6-digit counter ensure accurate life-cycle prediction, critical for validating warranty periods.

- Adaptive Fixture System: Interchangeable R-angle fixtures (R3.75, R7.2, R9.6, etc.) cater to wires from thin gauge (0.5mm²) to heavy-duty cables, eliminating costly retooling.

- Safety & Data Integrity: Automatic stop-on-break function prevents post-failure damage, while memory retention resumes testing after power interruptions.

Product Features

- Dynamic Swing Mechanism: 180° rotation with adjustable angles (1° increments) via digital control panel.

- Variable Speed Control: 10–60 cycles/minute operation with real-time speed display and over-speed protection.

- Modular Test Stations: Three channels with individual start/pause controls and LED status indicators.

- Load Configuration: Four precision weights (2.5N, 3.75N, 5N, 7.5N) for simulating varying vibration/flexure stresses.

- Diagnostic Capabilities: Built-in 24V test voltage output for continuity monitoring during bending cycles.

- Robust Construction: 50KG steel frame with vibration-damping feet ensures stable operation at maximum load.

Technical Parameters

| Parameter | Specification |

|---|---|

| Swing Angle Range | 0°–180° (CW/CCW), adjustable in 1° increments |

| Operating Speed | 10–60 cycles/min (±1 cycle tolerance) |

| Cycle Counter | 1–999,999 counts (presettable with pause/resume) |

| Test Stations | 3 independent channels with quick-release fixtures |

| Applied Loads | 2.5N, 3.75N, 5N, 7.5N (interchangeable weights) |

| Fixture R-Angle Options | R3.75, R7.2, R9.6 (customizable per AWG/mm²) |

| Test Voltage | 24V DC (built-in supply) |

| Power Input | AC 220V ±10%, 50/60Hz (switchable to DC 24V/5A) |

| Machine Dimensions (W×D×H) | 600 × 450 × 750 mm |

| Net Weight | 50 kg |

Accessories

- 4-Piece Weight Set (2.5N/3.75N/5N/7.5N) with Storage Case

- 3 × R-Angle Fixture Heads (R3.75, R7.2, R9.6)

- Spare Fuse Kit (2A/5A)

- Calibration Certificate (ISO 17025-compliant)

- Multilingual Operation Manual (English/Spanish/German)

- Fixture Removal Tool

Send product request

Other supplier products

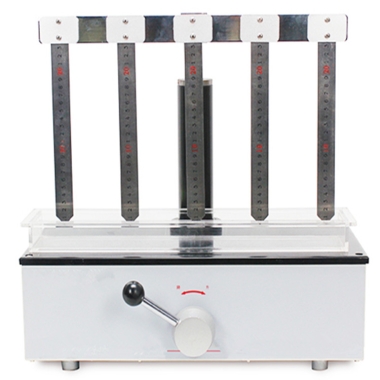

| Paper water absorption tester | Introduction: Paper water absorption tester, also known as Kleim test instrument, is suitable for the determination of the capillary suction heigh... | |

| Automatic IBC Tote Washer | STDIBC tote washer offers quick and effective cleaning for ibc container or totes, commonly seen in modern production plants. The system is compact... | |

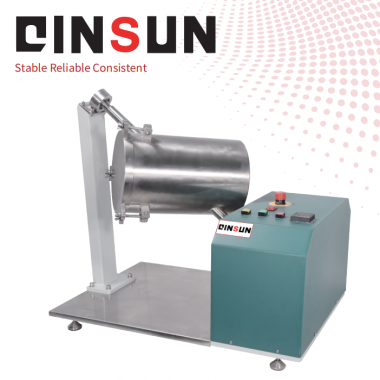

| Dental material color stability tester-QINSUN | Product description The Dentistry Base Polymer Search Stability tester is an instrument used to evaluate the color stability of dental base poly... | |

| Fabric ici pilling and snagging box-QINSUN | Standard GB/T 4802.3: China’s national standard for textile pilling resistance. BS EN ISO 12945-1: European standard for wool-based textile... | |

| Dry Cleaning & Washing Cylinder | Introduction The dry cleaning and washing cylinder consists of a stainless steel rotary test chamber and a multi-speed drive with a digital timer.... |

Same products

| Seat Bumping and Creep Test Bench | Seller: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Seller: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Seller: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Seller: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Seller: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |