LAG-S200 Ladle Slag Detection System (Vibration Type)

LAG-S200Ladle Slag Detection System (Vibration Type)

Overview

The continuous castingvibration typeladle slag detection device is used to detect the slag content of the ladle nozzle in the steelmaking continuous casting process, so as to improve the cleanliness of the tundish molten steel and obtain the best yield of the ladle molten steel. The device adopts the principle of vibration detection.

The LAG-S200 continuous casting ladle slag automatic detection system is developed by WuhanCenterRiseM&CEngineering Co., Ltd. after many years of researchwith many scientific research institutes,andfully combined with the actual situation on site.It has a real field application value as a continuous casting ladle slag automatic detection system.

Themeaning of the system

1. Reduce the amount of tundish slag

2. Improve the purity of molten steel

3. Improve the life of the tundish

4. Reduce sliding nozzle erosion

5. Reduce nozzle blockage

6. Increase the number of continuous pouring furnaces

7. Reduce the amount of residual steel in the ladle when high-quality steel is casting

8. Improve the yield of molten steel

9. Improve the quality of continuous casting billets

In order to improve the purity of the molten steel in the tundish, and improve the quality of the casting billet, especially to improve the quality of the billet in the transition section, and reduce the amount of residual steel in the high-quality ladle, and prolong the life of the tundish lining, and increase the number of continuous casting furnaces, it’s necessary to detect and control the slag in the later stage of continuous casting ladle casting.

The Working principle of the system

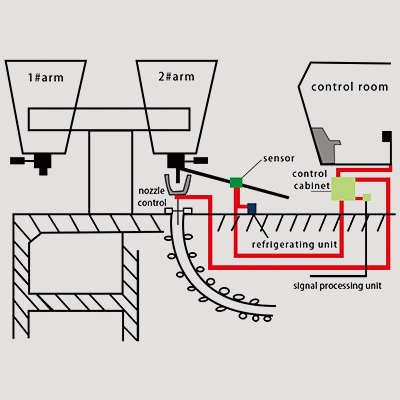

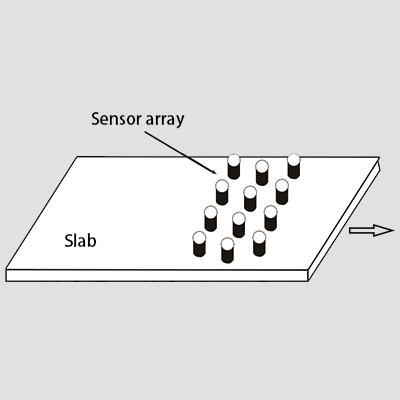

The LAG-S200 continuous casting ladleslagautomatic monitoring system detects the slag state during the pouring process by receiving the vibration signal of the mechanical operating arm of the ladle nozzle. In the process of molten steel pouring, when molten steel flows through thelong nozzleand pours into the tundish, the molten steel impacts the wall of thelong nozzleand causes thevibration of themechanical operating arm used to support thelong nozzle. Since the specific gravity of the steelmakingslag is less than half of the specific gravity of the molten steel, it floats on the surface of the molten steel, and the steelmakingslag appears when the molten steel is about to beallpoured. At this time, due to the high viscosity and poor fluidityoflight steelmakingslag, the impact force of the mixed flow of molten steel and steel slag on the wall of the long nozzle is quite different from that of pure molten steel.Thesystem mainly monitors the ladleslag of the continuous casting by measuring and analyzing the vibration difference of the mechanical operating arm.

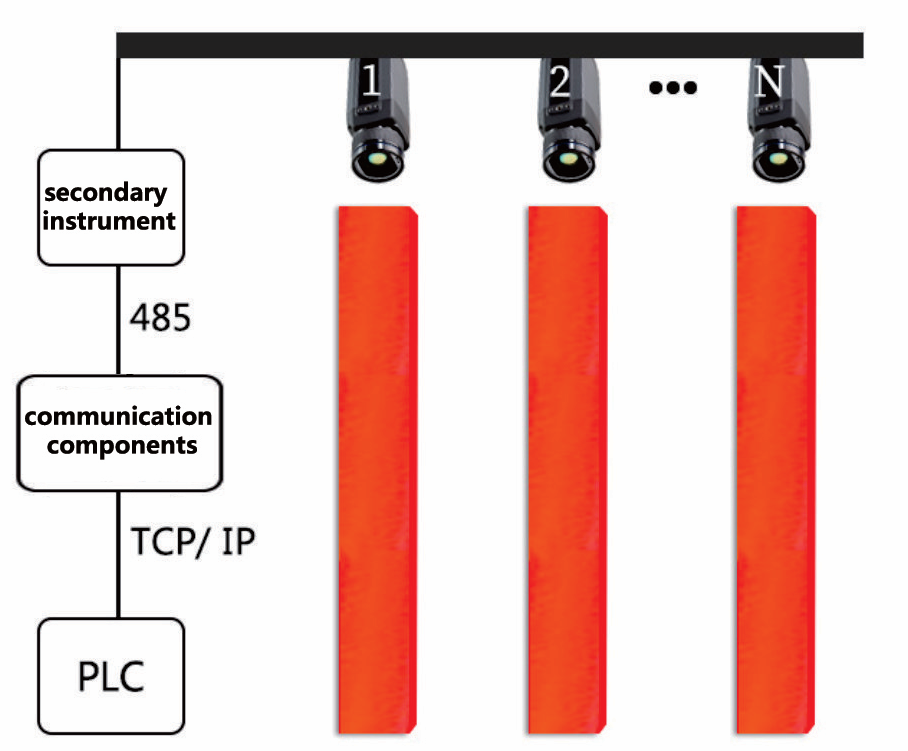

The vibration signal is connected to the operation control unit of the system control cabinet through the front-stage conditioning and amplification module through the sensor installed in the middle of the operating rod. After processing, it is output to the industrial computer for operation and analysis. The slag signal detected by the system is output from the system control cabinet to the front-end control unit, and then control the alarm horn and alarm light to work, or issue an instruction to close theladle nozzle.

The features of the system

(1) It is easy to install, basically no modification is made to the field equipment, and the installation and debugging work will not affect the normal production of the enterprise.

(2) The detection accuracy is high, and the effective rate is greater than or equal to 95%. The thresholdofslag volume is accurately set, the output control function is powerful. It has excellent performance in technical indicators such asthesensor service life and sensor usage times.

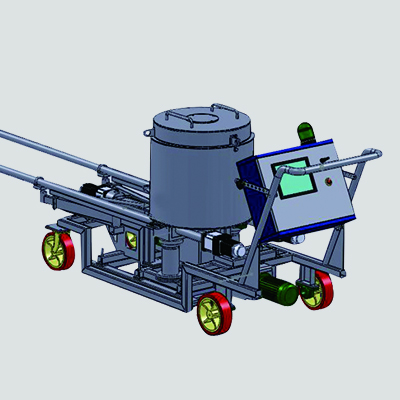

(3) The sensor is installed at a position far away from the molten steel, and is cooled by a special refrigeration device for 24 hours. The outer layer adopts a composite protection structure, which has a long service life.

(4) Adopt professional and targeted signal processing methods to obtain the vibration characteristic parameters of the ladle slag, and analyze, reason and judge the effective slag signal through the vibration signal database, which has a high accuracyofslag alarm.

(5) The architecture is established based on the artificial intelligence network, which has the functions of self-learning and self-induction.

(6) The equipment adopts a modular design. The failure of each module will not affect other parts,which ensuremore reliable operation of the system and easy maintenance.

(7) The alarm display device is used on site to visually indicate the flow state of molten steel and slag. When slag is unloaded,wecan choose to automatically close theladlenozzle or sound and light alarm at the same time, prompting the on-site operator.

(8) The system has a powerful database function. Including the comparison functionforlast twoladles of casting time record, the system automatically stores the running data, and generates a record file every day.

(9) The system has the function of automatically controlling theladle nozzle. The control unit is an auxiliary system of the system, which is interconnected with theladleslag detection system to automatically control the opening of theladle nozzleand realize the whole-process control of the liquid level of the molten steel in the tundish.

The composition of the system

The LAG-S200 slag detection system consists of: vibration detection sensor, pre-signal amplifier, slagdetection operation unit, tundish liquid level control unit, on-site operation indication box, and process control cabinet.

1. Vibration detection sensor: It is installed on the robotic arm connected to themolten steelto detect the vibration signal of the whole casting process of theladle.

2. Pre-signal amplifier: Amplify, convert and transmit the weak vibration signal detected by the vibration detection sensor.

3.Slagdetection operation unit:Analyze, judge and discriminate the vibration signal to realizethediscriminationofall steel, mixed slag and full slag , and output the slag alarm signal.

4.Tundish liquid level control unit:Accept the control signal of thetundishnozzleand theladlenozzle, and realize automatic or manual control of theladlesteel flow according to the requirements.

5. On-site operation instruction box: Provides man-machine exchange for slag alarm indication, fault indication, system activation mode selection, and control mode selection.For process control cabinet, providing power management, displayingman-machine interface and setting management.

The parameters of the system

1. The system controls the slag inclusion in molten steel with high precision and closes the nozzle in real time.

2. Improve the quality of steel, reduce defective products, and improve the yield.

3. The yield of molten steel is increased by 0.3%-0.5%. The nozzle can be automatically closed, so that the disadvantage of untimely manual response is overcome and less molten steel remains in the ladle. The threshold value of molten steel (slag threshold) is set by the user within a wide range.

4. No artificial factors are involved, high reliability, good repeatability or consistency.

5. The steelmaking slag does not pass through or rarely flows into the tundish, which increases the service life of the refractory material and the sliding nozzle.

6. Greatly reduce the blockage of the tundish nozzle and increase the number of continuous pouring furnaces of the tundish.

Send product request

Other supplier products

| MAC-G320 Automatic Mold Flux Feeding Machine | MAC-G320Automatic Mold Flux Feeding Machine Overview MAC-G320automaticmoldfluxfeeding systemis a new generation product ofautomaticaddingmoldfl... | |

| On-line Billet End Continuous Temperature Measurement | ZST-P100 On-line Continuous Temperature Measurement of the Billet End Overview Thesystem aimsat the continuous temperaturedetectionof theproducto... | |

| Ladle Comprehensive Management System | LDT-N200 Ladle Integrated Management System Overview: In the steelmaking production process, the ladle is the key equipment for holding molten ste... | |

| ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) | ZSQ-T100Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system TheZSQ-T100online surface qual... | |

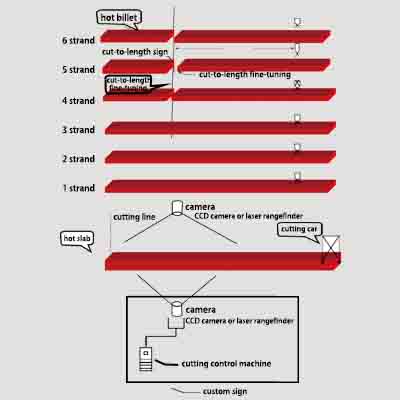

| Infrared/Laser Cut-to-Length Cutting System | Infrared/Laser Cut-to-Length Cutting System Overview The all-digital non-contact infrared automatic cut-to-length cutting system developed by W... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |