Ladle Comprehensive Management System

LDT-N200 Ladle Integrated Management System

Overview:

In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the most important partin the use and consumption of refractory materials. Improving the service life of ladles and reducing refractory consumption isthekey technology for steelmaking plants to save costsandreduce energy consumptionfor green production.

In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integratedmanagement system for the ladle.

Introduction:

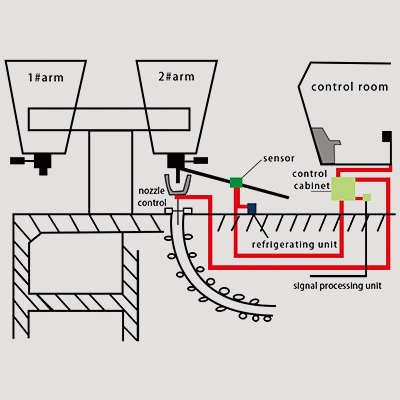

LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles.

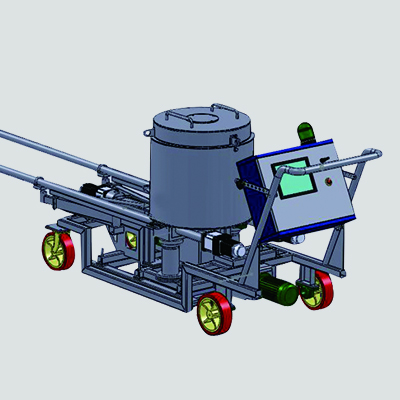

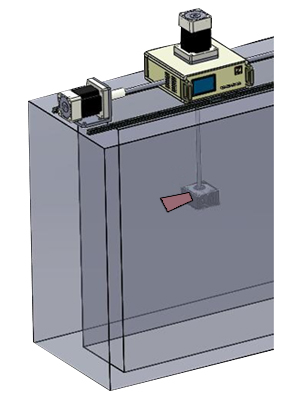

LDT-L200 ladle liningthicknessgauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladlelining, calculate the lining loss, and predict the service life of the ladle.

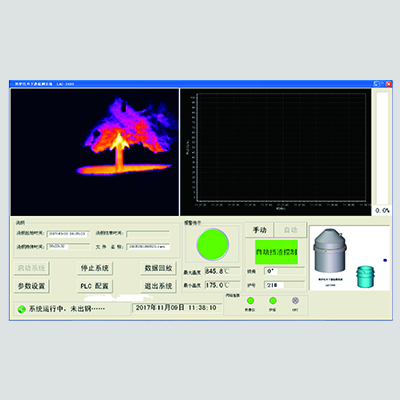

TBP-S300 ladle, tundishbakingtemperature andleakagemonitoringsystem uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage.

RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on allladles to realize full-time and full-space ladle positioning and tracking.

LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles.

LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials.

The features:

Usinga lining thickness gauge to measure the thickness of the ladle lining

Using infrared thermal imaging camera/embedded armor wire to realize ladle leakagedetection

Using RFID/number plate recognition to realize the location management of ladles

Ladle age management system based on overall tracking

Overall (full-time full-space) ladle management system based on database

Provide overall production scheduling data

Using neural network to predict ladle service life based on big data

Ladle Optimal Scheduling System based ondatabase andladleservice life

Increase the service life of ladle by 12%-20%

Reduce the use of refractory materials more than 15%

Realize orderly management of ladle baking

Realize full space and full time domain control

Reduce the costs of ladle management and maintenance

Improve the efficiency of ladle turnover operation

Send product request

Other supplier products

| LAG-S400 Infrared Converter Slag Detection System | LAG-S400Infrared Converter Slag Detection System Overview The infrared converter slag detection system uses a far-infrared thermal imager to mo... | |

| MAC-G320 Automatic Mold Flux Feeding Machine | MAC-G320Automatic Mold Flux Feeding Machine Overview MAC-G320automaticmoldfluxfeeding systemis a new generation product ofautomaticaddingmoldfl... | |

| Laser Mold Taper Measuring Instrument | MDC-L200 Laser Taper Measuring Instrument (Multi-dimensionalDetection) Overview: Laser taper measuring instrument(multi-dimensional detection) is ... | |

| Analog Heat Source Instrument | Overview: LGK-S107 analogheat sourceinstrument(heating tool) is independently developed and designed by WuhanCenterRise M&C CO.,. Thisinstrumen... | |

| LAG-S200 Ladle Slag Detection System (Vibration Type) | LAG-S200Ladle Slag Detection System (Vibration Type) Overview The continuous castingvibration typeladle slag detection device is used to detect... |

Same products

| Replacement of PALL HC8304FAN16H Hydraulic filter element | Seller: Xinxiang Saya Filters Co., Ltd | Product Advantages: 1. Using glass fiber from the American HV brand as the filter layer, the fil... | |

| Argo V2.1260-06 Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Performance characteristics of Argo V2.1260-06 Hydraulic Filter Replacement: 1. Good filtration p... | |

| Eaton Internormen Hydraulic Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Product Description: The filter elements have the characteristic on high pressure collapse resis... | |

| Sullair / Air Filter Replacement | Seller: Xinxiang Saya Filters Co., Ltd | Ayater air filter Introduction: ● Air Filter Element is a critical part of Compressor, made of hi... | |

| Replacement Of Paker Hydraulic Filter Element | Seller: Xinxiang Saya Filters Co., Ltd | AYATER hydraulic oil filter element is a mesh made of multi-layer metal stamping, which is manufa... |