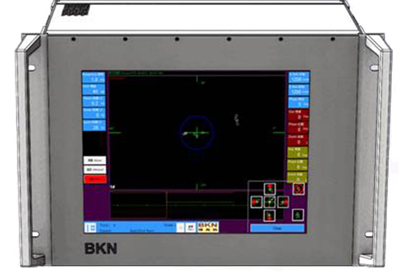

GTET-02 Cylinder Liner Eddy Current Testing Machine

We have eddy current machine for sale!

GTET-02 Cylinder Liner Eddy Current Testing Machine Introduction

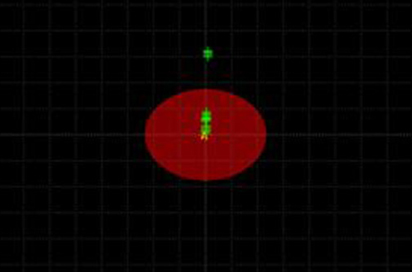

- The rate of missed standard defect is 0%; the rate of false positives (only misidentified products are judged as non-conforming products) ≤1%.

Detection method

Eddy current testing is to connect the conductor to the coil with alternating current. The alternating magnetic field is established by the coil. The alternating magnetic field passes through the conductor and electromagnetic induction is applied to establish an eddy current in the conductor.

The eddy currents in the conductor also generate their own magnetic field, and the action of the eddy current magnetic field changes the strength of the original magnetic field, which in turn causes a change in the coil voltage and impedance.

When a defect occurs on the surface or near-surface of the conductor, the intensity and distribution of the eddy current will be affected. The change of the eddy current causes a change in the voltage and impedance of the detecting coil. According to this change, the existence of the defect in the conductor can be indirectly known.

Since the shape of the test piece is different and the detection position is different, the shape of the test coil is different from that of the test piece. In order to meet various testing needs, various detection coils and eddy current testing instruments have been designed.

In eddy current testing, the detection coil is used to establish an alternating magnetic field; the energy is transmitted to the conductor to be inspected, and the alternating magnetic field established by the eddy current is used to obtain the quality information in the detected conductor. Therefore, the detection coil is a transducer.

The shape, size and technical parameters of the test coil are critical to the final inspection. In eddy current testing, the type of detection coil is often selected according to the shape, size, material, and quality requirements (testing standards) to be detected. There are three types of commonly used detection coils.

1) Through coil

The through the coil is a coil that detects the sample to be tested and put it in the coil and is suitable for flaw detection of tubes, rods, and wires. Since the magnetic field generated by the coil acts first on the outer wall of the sample, the effect of detecting the outer wall defect is good, and the detection of the inner wall defect is performed by the penetration. In general, the detection sensitivity of the inner wall defect is lower than that of the outer wall. The drawback of thick-walled tubing is that it cannot be detected using an externally wound coil.

2) Interpolated coil

The interposer coil is a coil placed inside the tube for inspection. It is used to inspect the defects of thick walls or the inner walls of the borehole. It is also used to check the quality of the tubes in the complete equipment, such as the in-service inspection of heat exchanger tubes.

3) Probe coil

The probe coil is a coil placed on the surface of the sample for inspection. It is not only suitable for surface scanning inspection of simple plates, slabs, billets, round billets, bars and large diameter pipes, but also for complex shapes. Inspection of mechanical parts. Compared with the through the coil, the probe coil is suitable for detecting small surface defects due to its small volume and small field action range.

BKNis an eddy current testing benchmark enterprise and has long been committed to the development and production of bearing hardness and crack eddy current screening equipment. If you want to know more details or want a quotation, just feel free to contact us!

在线联系供应商

Other supplier products

| BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator | Stimulating the coil makes a magnetic induction to the tested material. The induced electromotive force received by the testing coil is related to ... | |

| Bolt Vortex Sort BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Eddy Current Testing Equipment | Automatic EDM notch machineis the ideal equipment for processing artificial defects of pipe rod standards in non-destructive testing work. The flaw... | |

| Eddy Current Testing for Auto Parts | NDT Application in Automotive Industry: Eddy current hardness testingtechnology has been widely used in the detection of metal components in the... | |

| GTET-02 Cylinder Liner Eddy Current Testing Machine | We have eddy current machine for sale! GTET-02 Cylinder Liner Eddy Current Testing Machine Introduction The rate of missed standard defect is 0... |

Same products

| Lost Wax Casting Y Piece FlowSplit Fitting | 卖方: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

| Mini Nitrogen Generator | 卖方: 0000 | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

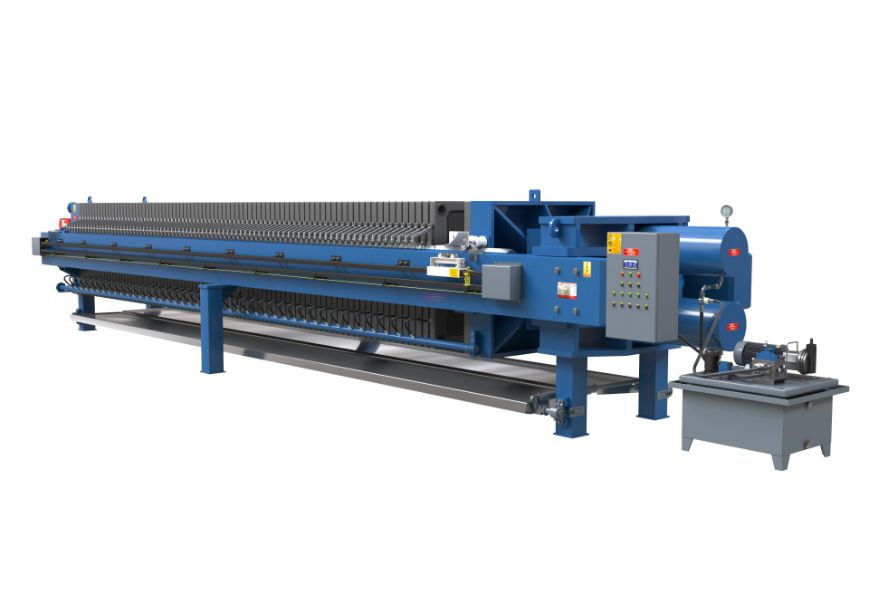

| filter press in chemical industry | 卖方: 00000 | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | 卖方: 大连卓晟科技有限公司 | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Dal... | |

| Intake Manifold in Car Engine | 卖方: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |