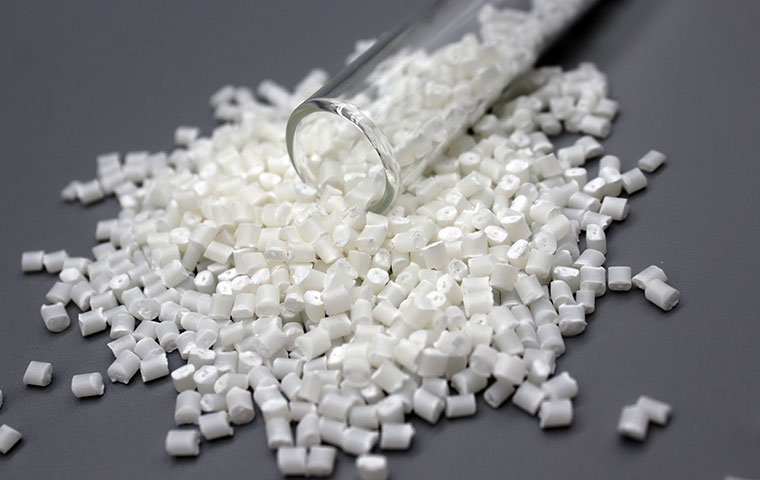

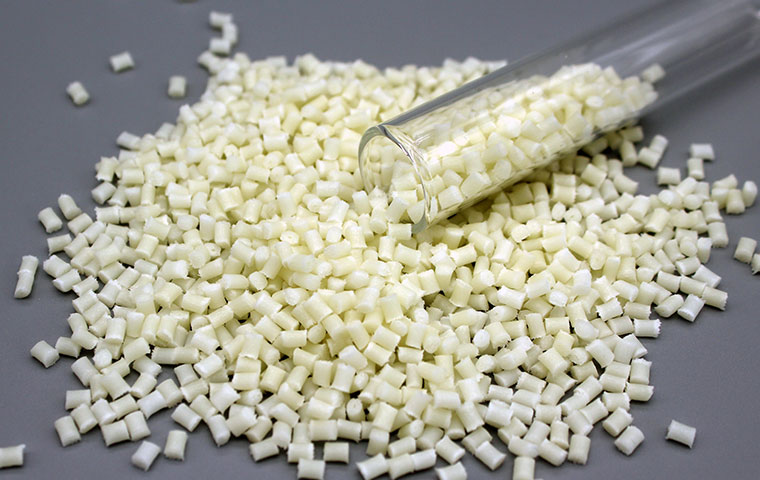

PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics

Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This type of polyamide PA66 contains stabilization and is optimized to use in electronic and electric applications. If you are interested, contact us now to get more information about Nylon PA66GF30price!

Material PA66 GF30Halogen-free FR Features

Halogen-free flame retardant nylon PA66 particles is a polyamide materials with new materials (phosphorus and nitrogen) as flame retardant elements. The glass fiber content is 30%. Has the following characteristics:

Material PA66 GF30 Halogen-free FR Features

Halogen-free flame retardant nylon PA66 particles is a polyamide materials with new materials (phosphorus and nitrogen) as flame retardant elements. The glass fiber content is 30%. Has the following characteristics:

▲High mechanical strength and good toughness

▲Outstanding fatigue resistance

▲High softening point

Halogen-free flame retardant PA66 material has a high heat distortion temperature, and its heat distortion temperature reaches more than 250 degrees

▲Wear-resistant

▲Corrosion resistance

▲Halogen-free fireproof PA66 has excellent electrical properties

▲Lightweight

Nylon PA 66 GF 30 Halogen-free FR Applications

The main advantage of PA 66 GF 30 halogenated FR is that PA66 FR can maintain the original physical and chemical properties of flame retardant products. Thus, nylon material pa66 gf30 is widely used in many industries as in the following.

lElectronics field-A series of slots and switches

lHome appliance-Internal structure parts of Automatic wok (cooking pot, new items)

lDaily necessities structural parts-connecting hinge of furniture

lIndustrial products structural parts-engine cooling fan

Material PA66 GF30 Halogen-free FR Processing Detail

Description of the resin extrusion process

The resin and additives are evenly transported to the raw material feeder through high-speed stirring. The flow rate is controlled by the feeder, and the mixed material is supplied to the extruder (special materials can be supplied separately). The material is plasticized and kneaded at high temperatures in the extruder and extruded into resin strips. Finally, it is cooled, diced, screened, and dried to make granules of uniform size.

Other Details of NYLON Material PA66 GF30 Halogen-free FR (A2015F)

|

Physical Property |

|

|

Ash |

(30.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1530Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.2-0.5 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.6-0.9% I ISO294-4) |

|

Mechanical Properties |

|

|

Tensile strength (105.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.6% I ISO527) Conditioned |

5mm/ min |

|

Notched Impact Strength (10.0 KJ/m2 I ISO179) Conditioned |

|

|

Flexural Strength (177MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (5050 MPa I ISO178) Conditioned |

2mm/min |

|

Thermal Property |

|

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(248*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

|

|

Injection Molding Conditions |

|

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

280-300°C |

|

Nozzle Temperature |

280-300*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions are just for reference, please make an adjustment based on the actual situation!

If you have needs to buy masterbatch, please contact us.

As a reliable engineering plastic supplier, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| PA6 GF20 Heat Stabilized (A1006D, A1016D) for Engineering Plastics | PA6 GF 20has 20% glass fiber filler. It has much greater heat-resistant mechanical properties than unfilled polyamide. Anmeiplastics has always bee... | |

| Antimicrobial Masterbatch | Antibacterial Masterbatchfor Engineering Plastics Polymer anti-bacterial masterbatch is a kind ofmasterbatch materialthat adds antibacterial agent... | |

| TPU Slip Masterbatch & Frosted Matte Masterbatch for Engineering Plastics | Anmei company specializes in the production of TPU slip masterbatchingredients and TPU frosted matte masterbatch excellent dispersibility in cast f... | |

| Antibacterial Masterbatch for Engineering Plastics | Polymer anti-bacterial masterbatch is a kind of masterbatch materialthat adds antibacterial agents into the carrier resin, which is offering antimi... | |

| Nylon66 pa66 | Nylon 66 is polyamide 66. The main purpose of Nylon 66 plastic modification is to improve the properties of Nylon 66 material based on the original... |

Same products

| Defoamer Powder | 卖方: Shandong Jufu Chemical Technology Co., Ltd. | Antifoaming agent powder primarily serves as an essential component in cement and concrete produc... | |

| PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% ... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF3... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This t... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Applic... |