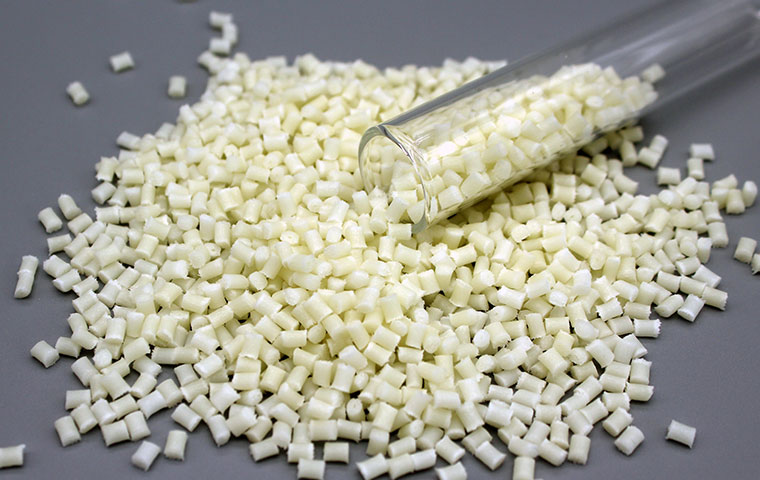

PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics

PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% glass fiber is added to nylon 66.

Typical Application of PA66 GF35(A2000G)

It is applied to lamp holder cover and cooling fan, gears and various electronic connectors, wear-resistant parts of elevators, and internal and external structural parts around the engine such as cooling fan.

Processing Detail of PA66GF35(A2000G)

Other Details of PA6.6 GF35(A2000G)

|

Physical Property |

|

|

Ash |

(35.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1407Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.2-0.4 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.5-0.8% I ISO294-4) |

|

Mechanical Properties |

|

|

Tensile strength (105.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.6% I ISO527) Conditioned |

5mm/ min |

|

Notched Impact Strength (10.0 KJ/m2 I ISO179) Conditioned |

|

|

Flexural Strength (177MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (5050 MPa I ISO178) Conditioned |

2mm/min |

|

Thermal Property |

|

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(255*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

mm |

|

Injection Molding Conditions |

|

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

280-300°C |

|

Nozzle Temperature |

280-300*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions are just for reference, please make an adjustment based on the actual situation!

As a reliable plastics engineering company, we will do our best to meet all the needs of customers.

Want To Buy High-quality PA material as Engineering PlasticMasterbatch? Come to Anmei, a professional engineering plastic/masterbatch company!

在线联系供应商

Other supplier products

| PA66 GF15 Heat Stabilized (A2006C, A2016C) for Engineering Plastics | PA66 GF 15Heat Stabilized (A2006C, A2016C) for Engineering Plastics PA 66 GF 15is a 15% glass fiber reinforced, heat-resistance, polyamide 66 resi... | |

| Engineering Plastic & Masterbatch in Anmei | ANMEI, YOUR PROFESSIONAL PLASTIC SUPPLIER! Contact US TODAY ANMEI focuses on supplying the 5G New energy and intelligence appliance market with en... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This type of polyamide PA66 contains stabilization and i... | |

| Antibacterial Masterbatch for Engineering Plastics | Polymer anti-bacterial masterbatch is a kind of masterbatch material that adds antibacterial agents into the carrier resin, which is offering antim... | |

| Nylon66 PA66 Halogen-free FR (A2005X01) for Engineering Plastics | Flame-retardant PA66 is a halogen-free flame retardant engineering plastic made of nylon 66 resin as a base material (other fibers can also be adde... |

Same products

| Defoamer Powder | 卖方: Shandong Jufu Chemical Technology Co., Ltd. | Antifoaming agent powder primarily serves as an essential component in cement and concrete produc... | |

| PA66 GF35 (A2000G, A2011G, A2111G) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | PA66 is nylon 66, namely pa66_gf35is glass fiber. Generally expressed as PA66 GF35, that is, 35% ... | |

| PA66 GF30 Heat Stabilized (A2006F, A2016F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | Polyamide 66, reinforced with 30% of glass fiber, heat stabilized, forinjection moulding. PA66GF3... | |

| PA66 GF30 Halogen-free FR (A2015F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | Material PA66 GF30FR is a PA66 with 30% glass-fibers and flame retardant free of halogens. This t... | |

| PA66 GF30 Halogenated FR (A2014F, A2114F) for Engineering Plastics | 卖方: Suzhou Anmei Material Technology Co., Ltd | PA66GF30FR is a Nylon 66 with 30% glass-fibers and flame retardant halogenated. Typical Applic... |