Reasons Why the Feeder Affect the Pick and Place Efficiency of the SMT Pick and Place Machine

The influence of the feeder on the pick and place efficiency of the SMT feeder pick and placemachine is mainly concentrated on the abnormal power supply. The drive mode of the feeder is motor drive, mechanical drive and cylinder drive. Here, the mechanical drive is taken as an example to illustrate the influence of the feeder on the pick and place efficiency of the pick and place machine.

Generally, the maintenance of the feeder of the SMT pick and place machine is easy to be ignored, but regular cleaning and lubrication are essential tasks.

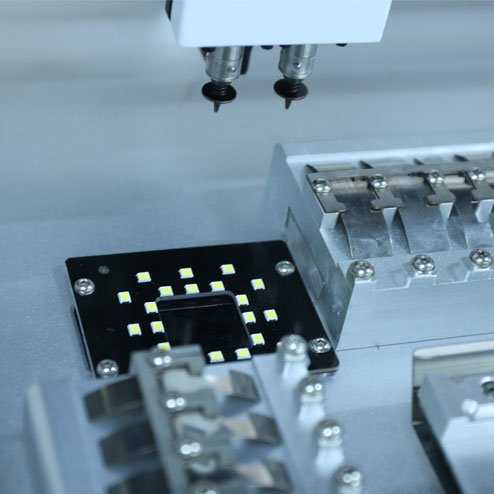

The feeding mechanism is mechanically driven by the cam main shaft to quickly tap the striker arm of the feeder. Through the connecting rod, the connected ratchet wheel drives the component tape to advance by one feed pitch, and at the same time drives the plastic take-up reel to peel the plastic strip on the tape, and the suction nozzle is lowered to complete the pick-up action.

However, due to the high-speed access of the feeding mechanism to the feeder stol, after a long period of use, the pawl of theSMT pick and place machinefeeder is severely worn, causing the pawl to fail to drive the plastic strip of the take-up reel to peel normally and making the suction nozzle unable to complete the pick-up work.

Therefore, the feeder smt machineshould be carefully checked before installing the tape. The feeder with a worn-out pawl wheel should be repaired immediately, and the one that cannot be repaired should be replaced in time.

In terms of SMT pick and place smt machine feeder, due to long-term use or improper operation by the operator, the press belt cover, needle, spring and other moving mechanisms are deformed, rusted, etc., which will cause the deviation of sucking components, warping of components or failure to suck the components, so it should be check regularly and problems should be dealt with in time if found, so as not to cause a lot of waste of components.

At the same time, when we are installing the feeder of SMT pick and place machine, it should be correctly and firmly installed on the feeder platform, especially the height detection equipment of feeder, otherwise it may cause the feeder or even the machine to be damaged.

As one of smt equipment manufacturers, we have types of small smt pick and place machinefor sale, if you have needs, please contact us.

在线联系供应商

Other supplier products

| STENCIL PRINTER | The types of SMT printer machineare divided into three parts: 1. Manual printing table 2. Semi-automatic solder printer machine 3. Fully automatic ... | |

| Reflow Oven Soldering Process | The reflow soldering processis a surface-mounted board, and its process is more complicated which can be divided into two types: single-sided mount... | |

| Pick and Place Machine | The pick and place machine is the equipment used to achieve high-speed and high-precision placement of components in the production line, it is con... | |

| Semi Automatic Pick And Place Machine | This kind of pick and place machine features a dual head, 25 feeder slots, a vision system, and a flexible positioning system. The semi-automatic/m... | |

| Automatic Pick and Place Machine | TronStol A1 is the latest high-precision laser flying mounter developed by our company, which can stably and efficiently mount high-precision compo... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |