H Beam Shot Blasting Machine

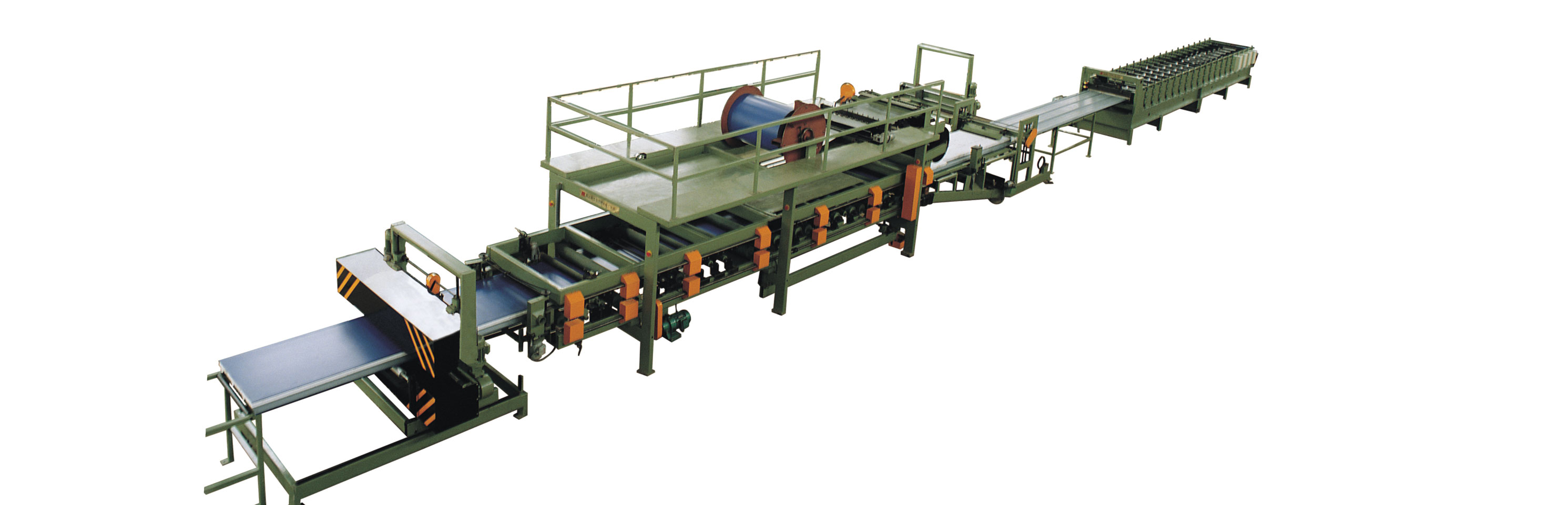

Hbeam shot blasting machineis designed and manufactured to clean the surface of the section steel. It is ideally suited for removing the rust, scale and contamination from the steel surface, which can make the surface clean, bright but with a certain coarseness. So the paint film can attach to the steel surface more firmly, thus improving surface quality and the anti-corrosion capacity.Our steel structure shot blasting machinemainly consists of shot blasting chamber, workpiece transport system, shots circulation system, dust removing system, electrical control system, etc.

The length of this machine is about 31m; the height is less than 6.4m. The abrasive diameter is from 1.2 ~ 1.5mm, and the conveying speed is about 0.4~4.5m/min (Frequency conversion speed regulation).For the covering area, it takes about 15000×1000×1800mm.

As a famous H-beam shot blasting machine manufacturer in China, we can design and manufacture different specifications according to different requirements of the client.

The components included of this production line:

1). shot blast cleaning chamber system

2). roller conveying system

3). pill material circulation system

4). dust removal system

5). electrical control system

Technical Specifications of H-beam Shot Blasting Machine

|

Item |

Parameter |

|

Accessible section dimensions(W×H×L) |

1200×2500×20000mm |

|

Effective clean section area(W×H) |

1200×2500mm |

|

Productivity |

|

|

Surface cleanness A-B |

Sa2~Sa2.5(GB8923-88) |

|

Surface roughness |

15~50µm(GB1030-83) |

|

Impeller head |

PD-11 impeller head |

|

Quantity |

12 sets |

|

220×12=2640kg/min |

Special Features About H-beam Shot Blasting Machine

Our shot blasting machine is the pretreatment equipment for cleaning welded structures, H steel and shaped steel. It is mainly used to perform the function of shot blasting towards the surface of raw steel material, which can remove rusty scale, welding slag and roll scale on the surface, thus obtaining uniform metal luster. The shot blasting machine can not only improve the finishing quality and corrosion resistance of the steel plate, but also reduce labor intensity and environment pollution.

Jinggongis a professional roll forming machine company, we provide continuous sandwich panel line, sandwich panel machine line, flame cutting machine for sale, etc.

在线联系供应商

Other supplier products

| PU/PIR Continuous Sandwich Panel Production Line | Continuous PU Sandwich Production Line, also calledpolyurethane sandwich panel manufacturing linemachine, is an automatic production line, which is... | |

| Rockwool Continuous Sandwich Panel Production Line | The rock wool sandwich panel lineis one continuous and automatic line that integrates mechanism, electrical controlling, hydraulic system and polyu... | |

| EPS Sandwich Panel Machine Line | Main structure features ofEPS Panel Machine 1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and high ef... | |

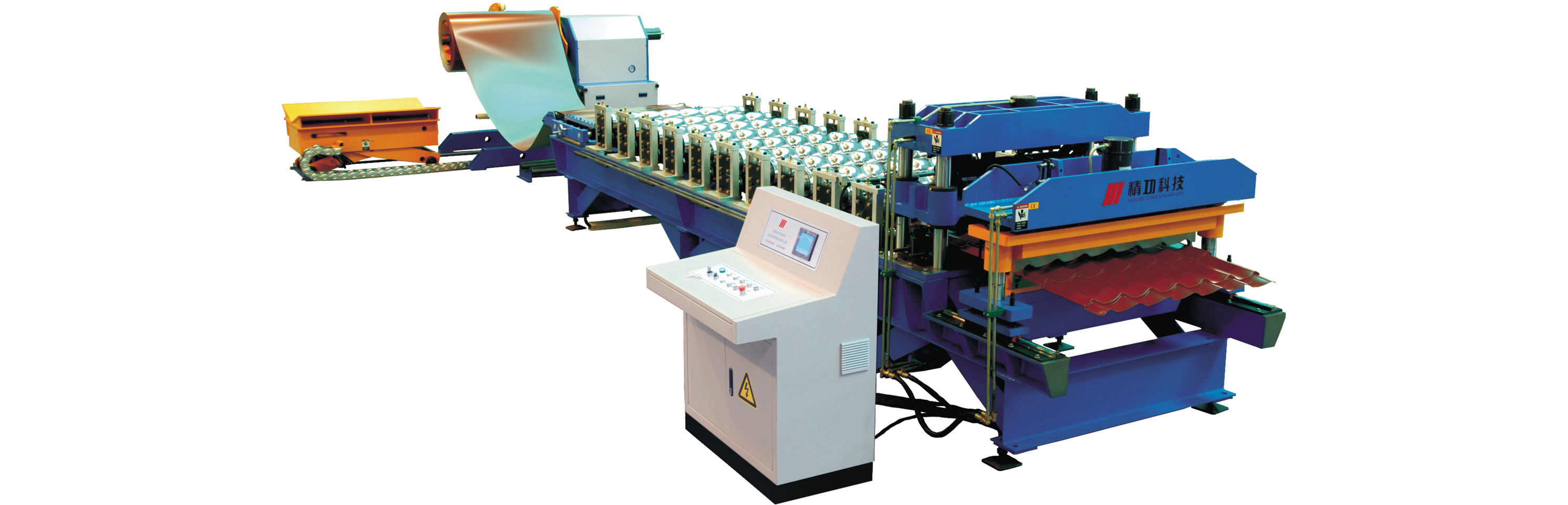

| High Speed Tile Forming Machine | This series of high-speed tile roll forming machineis a new-generational type roof tile roll forming machinewith high speed and high-efficient, inc... | |

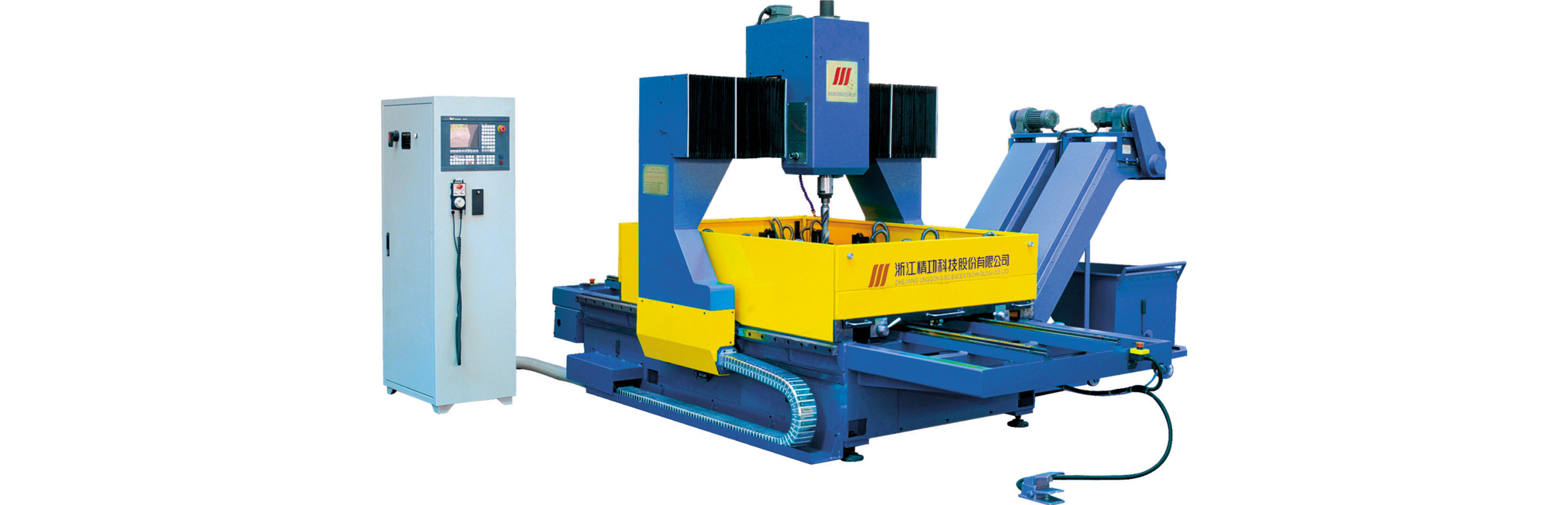

| CNC Drilling Machine | This CNC drilling machineemploys AC servo motor to drive the X axis and Y axis, while its Z axis is positioned by high accuracy raster ruler. By us... |

Same products

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | 卖方: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |