GlobeCore Transformer Oil Regeneration Plant

The Plant’s design includes Fuller’s Earth reactivation in situ for continuous reuse of Fuller’s Earth. Fuller’s Earth regeneration facility will allow oil processing to be carried out using one set of columns whilst the other set is reactivating. Alternatively oil processing or reactivation could be carried out in all columns.

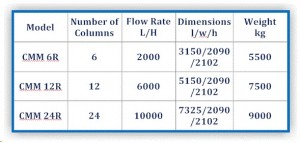

GlobeCore CMM-R plant comprises degassing and regeneration units. Its design allows for stationary as well as mobile operation when mounted on a roadworthy trailer. Plants vary in the numbers of Fullers Earth columns. GlobeCore plants are available with 6, 12 or 24 columns as required for different flow rates.

The CMM-R plant is fully controlled via a SCADA system from a Laptop, positioned within the operators compartment, and a touchscreen on the control panel. Valve operation is effected via solenoid controlled compressed air. Included on the control system is a manual override mode. During operation, degassing and regeneration units shall be connected to a transformer. Oil is drawn into the degassing unit where it is heated to operational temperature and filtered. Oil is then pumped into the regeneration unit and back to the degasser for the removal of moisture and dissolved gasses. Figure below depicts the schematic arrangement of the CMM-R plant.

Comparing to older technology where Fuller’s Earth is used only once and then must be disposed together with oil and harmful contaminants, GlobeCore CMM-R plants utilize the principle of sorbent (Fullers Earth) reactivation and have a number of unique features:

Extend transformers lifecycle by 25 to 30 years

Regenerate the oil on energized transformer

Remove sludge from cellulose insulation

Reactivate the sorbent (Fuller’s Earth) allowing the sorbent to stay in the plant for 2-3 years before replacement is needed.

Oil regeneration and Fuller’s Earth reactivation is fully automatic.

Disposal of sorbent is environmentally friendly and safe as Fuller’s Earth is free from oil and contaminants.

在线联系供应商

Other supplier products

| GlobeCore Transformer Oil Regeneration Plant | The Plant’s design includes Fuller’s Earth reactivation in situ for continuous reuse of Fuller’s Earth. Fuller’s Earth regeneration facility will a... | |

| Globe Core Transformer Oil Purification Plant CMM (UVM) 10 with High Vacuum | Removes Water from 100 ppm down to 10 ppm and from 50 ppm to 5 ppm in a single pass (ASTM method D-1533) Reduces Gas content from fully saturated w... | |

| GlobeCore UVB-2 modified bitumen batch unit 4-7 m3 per hour | UVB-2 modification unit is designed for production of modified bitumen, including polymer bitumen binding for preparation of top coat asphast-concr... | |

| GlobeCore UMBP-22P capacity 22 m3 per hour | UMBP-22P bitumen modification unit is designed for production of modified bitumen, including polymer bitumen binding for preparation of top coat as... | |

| GlobeCore INEY transformer oil refrigeration unit | GlobeCore is proud to offer INEY vacuum and refrigeration drying cold trap for processing of solid insulation in transformers in the range of 110 &... |

Same products

| UV Detector | 卖方: 淮安市鑫盛制药设备有限公司 | A DAC column,or Dynamic Axial Compression column,is a self-packingcolumn used for separation in l... | |

| YCS 手机屏幕后盖拆卸 | 卖方: 深圳维客修科技有限公司 | 描述 YCS 多功能拆框机,适用于手机平面/曲面 LCD 屏幕分离和后盖拆卸。YCS 拆框机预装通用手机摄像头镜头孔,可快速分离屏幕,同时保护手机摄像头。 特点: 1. 多用途:YCS 多功能... | |

| Bio-Pro全自动层析系统 | 卖方: 淮安市鑫盛制药设备有限公司 | iBio®系列全自动层析系统根据GMP和ASME BPE相关要求进行设计,集成了系统流路模块和自动化控制模块,可自动并连续进行平衡、上样、洗脱、自动收集、在线清洗等工艺过程,实现工艺流程... | |

| Mcc450 手动层析柱 | 卖方: 淮安市鑫盛制药设备有限公司 | 产品概述 MCC450手动层析柱是根据cGMP法规为生物制品中试放大而设计的,分配结构与自动柱ACC保持一致,可以实现柱效的线性放大。MCC手动层析柱采用了肖特精加工玻璃设计,无论在产品品质还... | |

| Mongoose MD2/3 Shale Shaker Screen | 卖方: Tangshan AngXin Technology Co.,Ltd | Mongoose MD2/3 shale shaker screen fits for Swaco mongoose MD series shale shakers. The material ... |