Comprehensive Lithium Battery Safety Performance Testing System BE-JKXT-08

1. Introduction

Integral Battery safety control system is mainly appliedto test battery performanceswhen batteryin hazard environment or damaged externally by electrical test and mechanical test, which is introduced by research institute and battery manufacturers.

It is complied with standards fromUL, IEC, UN, GB, QC, YDetc, and designed with remote test method to perform testing projects.

2. Features

Available to customize by increasing or reducing testing projects in compliance with customers’ demands or different standards;

One Control cabinet to control all testing systems;

Compartment design can be available to make all equipment in same height with the advantage to reduce to time , cost and mobile to move & upgrade test equipment.

3. Main Technical Parameters

|

Crush, Nail Penetrate |

||||||

|

Test Method |

Crush |

The test battery is placed between two planers and approximate 13KN crush force can be performed through hydraulic arm with an 32 mm diameter piston or bench clamp; The crush remains till hydraulic pressure reading data up to 17Mpa. Once crush force reached and system will release automatically; |

||||

|

Nail Penetration |

Battery specimen is placed and fixed in a planner, nail penetration speed at 10mm ~ 40mm remains to setting time and pull out steel nail automatically to complete test. |

|||||

|

Main Technical Parameter |

Pressure Range |

10KN~15KN(Controllable) |

||||

|

Top Crush Tray Diameter |

150mm (larger than or equal to 20cm²) |

|||||

|

Force Accuracy |

±1% |

|||||

|

Driven Method |

Hydraulic |

|||||

|

Nail Penetration Speed |

Speed at 10~60mm/s (Controllable and digital display) |

|||||

|

High Temperature Nail |

φ3 &5mm |

|||||

|

Nail Penetration Relay Time |

0~9999 s(controllable) |

|||||

|

Impact |

||||||

|

Test Method |

Battery specimen is placed on a planar, a bar with its diameter is placed on the center of the battery specimen, a weight at 9.1kg drop onto battery specimen from height of 610mm. Battery crush is placed onto shock bench, a weight drop free from a height of 100mm to hit the fixed battery (the max. Area side is vertical to bench); |

|||||

|

Main Technical Parameters |

Drop Weight |

9.1kg, 10kg |

||||

|

Drop Height |

0~1000mm(Digital Display) |

|||||

|

Cross Bar Diameter |

15.8 mm |

|||||

|

Elevating Method |

Electrical Elevating |

|||||

|

Low Air Pressure |

||||||

|

Test Method |

Battery is placed into vacuum oven after recharged. After sealed, reduce air pressure less than and equal to 11.6Kpa (altitude at 15240m) and remain 6hours for testing. |

|||||

|

Main Technical Parameters |

Vacuum Rate |

1.3Kpa |

||||

|

Air Pressure |

0~100Kpa Controllable |

|||||

|

Display Method |

Digital |

|||||

|

Unit |

Kpa |

|||||

|

Timer |

0~9999(Hour ,Mminutes ,Second change-over) |

|||||

|

Internal Dimension |

W500 X D500 X H500mm |

|||||

|

Internal Material |

SUS 304# Stainless Steel (thickness 6.0mm) |

|||||

|

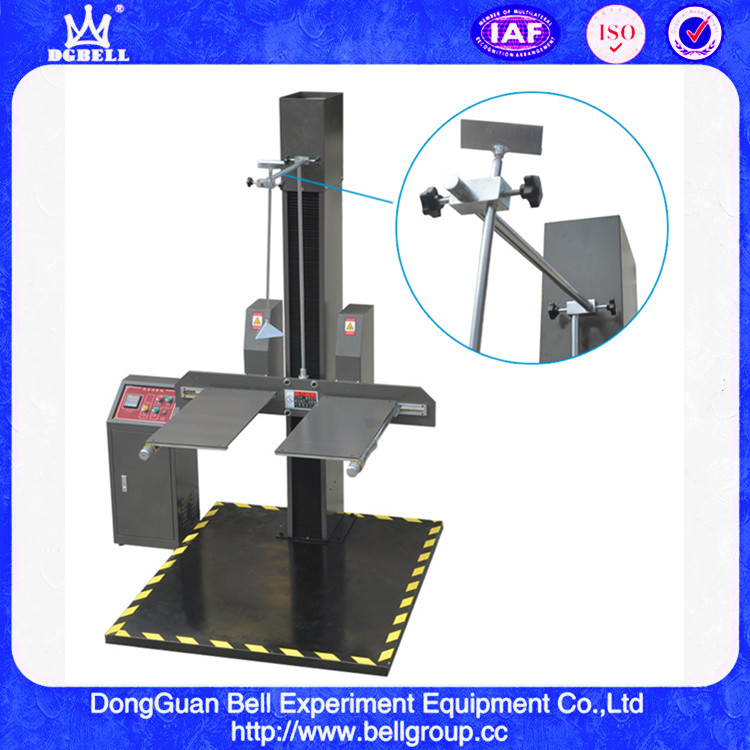

Free Drop |

||||||

|

Test Method |

Battery specimen drop free from a height of 100mm onto the concrete. Each side of battery for drop test, total 6 tests |

|||||

|

Main Technical Parameters |

Drop Height |

300~1500mm |

||||

|

Lifting Method |

Electronic Lifting |

|||||

|

Drop Method |

Hydraulic Drop |

|||||

|

Testing Point |

Free falling |

|||||

|

Drop Plate Material |

Concrete board, marble board, wooden board for selection |

|||||

|

Short Circuit |

||||||

|

Test Method |

In a condition of 55±5℃, battery is connected to thermal coupling (contact of thermal coupling is fixed onto the center of the max. area side of battery) and placed in vent cabinet and make circuit-circuit for positive pole and negative pole with short-circuit of 80mΩ±20mΩ, any condition listed below will stop test: A.. Battery temperature drop to 20% of peak value; B.Short-circuit time reaches 24 hours |

|||||

|

Main Technical Parameters |

Temp. Range |

RT+10℃~100℃or 0~100℃( with compressor cooling to maintain temperature below ambient temperature) |

||||

|

Temp. Fluctuation |

±1℃ |

|||||

|

Temp. Deviation |

±2℃ |

|||||

|

system internal resistance |

80mΩ±20mΩ(optional ) |

|||||

|

Max. Short circuit current |

1000A or customize |

|||||

|

Internal Dimension |

W500 X D550 X H500mm |

|||||

|

Thermal Shock |

||||||

|

Test Method |

Battery is placed in hot oven with temperature rises at a rate of(5±2)℃/min to (150±2)℃ and remain 30 min. |

|||||

|

Main Technical Parameters |

Temp. Range |

RT+10℃~+180℃ controllable |

||||

|

Temp. Deviation |

±2℃ |

|||||

|

Temp. Rising Speed |

5℃±2℃/min(linear, controllable) |

|||||

|

Internal Dimension |

W500×D500×H600mm |

|||||

|

Burning |

||

|

Testing Method |

Battery is placed in a hole with its diameter 4 inches and a cover place onto the plane bench. The cover plate is made of 20 holes per inch steel mesh or steel wire at 0.017 inch (0.43mm); a mesh screen with 8 sides at size of 2 inches(610mm width) and 1 inch (305mm height) is surrounded; The metal mesh is made of 16-18 wires per inch with wire diameter of 0.010 inch (0.25mm) metal wire. Specimens is placed onto metal mesh , cover on the central hole and heat to explode or damage. |

|

|

Main Technical Parameters |

Burner |

Bunsen Burner, internal diameter of lamp at 0.375 inch (9.5mm) with length 100mm |

|

Burning Time |

0~9999 H,M,S Free setting |

|

|

Flame Height |

Controllable |

|

|

Test Bar |

Diameter 6.35mm,Height 305mm |

|

|

Octagon cage subtense size |

610mm |

|

|

Edge size |

Top & bottom edges size of octagon should be 12.7 x 12.7mm |

|

|

Testing Hole |

Diameter 102mm |

|

|

Firing Devices |

Auto fire( remote control in 8 meters) |

|

在线联系供应商

Other supplier products

| DGBell Environmental Low / high Temperature & Damp Heat Test Chambers | Application . Standard Compliance : GB/T10586-2006 Specifications for damp heat chambers,GB/T10592-1989 Specification for low/high temperature test... | |

| 2 or 3-Zone Constant Temperature Thermal Shock Chamber Testing Machine | Applications This equipment is widely applied for electronic and electric products, components and materials by constant high low temperature, temp... | |

| Double Wings Package Drop Impact Tester Drop Testing Machine BF F 415D | Applications Drop Impact Test machineis to test large and heavy package products’ drop impact performance throughsimulate real face ,edge and... | |

| IEC62133 & UN38.3 Battery Crush / Squeeze Test Equipment | Applications Test battery safety performance through crush, after test the sample shall not explode or catch fire.This equipment becomes necessary... | |

| UL1642 Battery Squeeze Machine Nail penetration Testing BE 6047 | Application To test battery safety performance by crushing & nail-penetration through real-time test data ( battery voltage, max. battery tempe... |

Same products

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | 卖方: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | 卖方: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | 卖方: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | 卖方: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |