Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

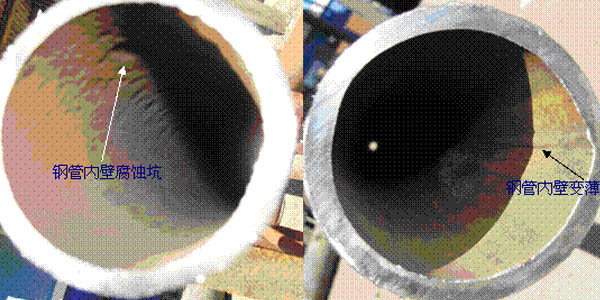

During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all defects.

The cause of the cracks in the bearing rings is complicated. From the raw materials to the finished products of the ferrules, if the process is not proper, the cracks may be directly caused or the hidden cracks may be buried for the occurrence of the lap ring grinding cracks.

There are many ways to form cracks in bearing rings: Raw material defects include: cracks in raw materials and the effects of raw material defects on the grinding process.

Forging defects include forging cracks, effects of forged microstructure defects on the grinding process, and cutter cracks. There are also various heat treatment defects and the like. Therefore, crack detection and hardness testing are essential. As one of the experienced non destructive testing equipmentmanufacturers, BKNoffers the perfect combination of Bearing Ring Crack and Hardness Combination testing equipment. Our advanced crack testing equipmentenable accurate and efficient crack detection, ensuring the quality and integrity of forged components.

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 Brief Introduction

Detection process

Vibrating plate and string charging →hardness test→crack detection→automatic blanking

↓

Bad product sorting

Automatic charging —automatic detection—automatic sorting —automatic blanking

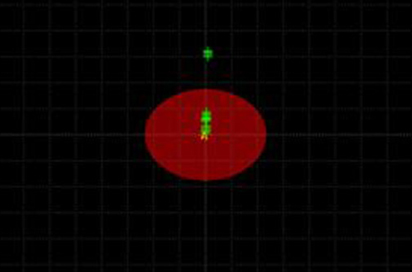

Crack sensitivity: a crack with a depth of ≥0.05 mm and a length of ≥1 mm extending inward from the surface of the ferrule; for a crack that has not extended to the surface inside the ferrule, when the thickness between the subcutaneous surface and the surface of the workpiece is ≤0.2 mm, the depth is ≥0.20 mm Cracks of length ≥ 1 mm can be detected.

Hardness sensitivity: Rockwell 1HRC ~ 2HRC (other parameters remain stable and consistent).

在线联系供应商

Other supplier products

| Eddy Current Testing Equipment | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a lead... | |

| Steel Pipe Testing | Steel having a hollow section that is much longer than the diameter or circumference. According to the cross-sectional shape, it is divided into ro... | |

| Bolt Vortex Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |