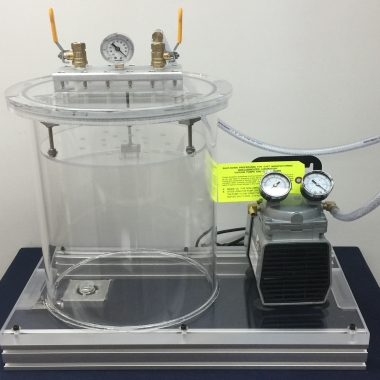

Pump and Valve Contamination Tolerance Tester

Meet the standard:

ISO 4406 ISO 18413

ISO 10707 ISO 6403

ISO 10372 NFPA T2.6.1

Product Introduction:

Solid particle contamination is a major cause of wear, silting, stiction, leakage, and ultimately failure in hydraulic pumps and valves. A Pump and Valve Contamination Tolerance Tester provides a controlled environment to subject both component types to contaminated fluid and assess their performance over time.

The tester typically consists of a hydraulic test circuit where the pump(s) and valve(s) under evaluation are installed. A reservoir holds a volume of test fluid (hydraulic oil) which is intentionally contaminated with a specific type and concentration of solid particles.

The pump circulates this contaminated fluid, and the system includes a loading mechanism (e.g., restrictors, actuators) to operate the pump and cycle the valve(s) under realistic pressure, flow, and temperature conditions.

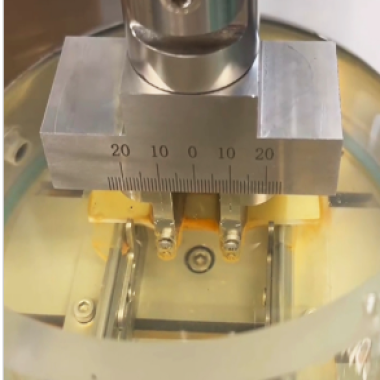

Throughout the test, which may involve running for extended durations or millions of cycles, the performance of both the pump and the valve(s) is monitored. Pump performance measurements include flow rate (volumetric efficiency), pressure, speed, and potentially power consumption.

Valve performance measurements vary depending on the valve type (directional control, pressure control, flow control) but can include leakage rate, pressure control accuracy, flow regulation accuracy, response time, and the force or current required to shift spools. The cleanliness level of the circulating fluid is continuously or periodically verified using fluid sampling and particle counting according to standards like ISO 4406. After the test, component performance is re-measured, and the pump and valve(s) are often disassembled for detailed visual inspection and quantitative measurement of wear on critical surfaces. This comprehensive evaluation provides crucial data on how contamination affects the operational lifespan and performance stability of both pumps and valves.

The instrument is used for:

Evaluating the wear resistance and durability of hydraulic pumps and valves simultaneously under contaminated fluid conditions.

Determining the impact of fluid contamination on the performance characteristics (efficiency, leakage, control accuracy, response time) of pumps and valves over time.

Validating the contamination tolerance of pump and valve designs, materials, and manufacturing processes.

Benchmarking the contamination resistance of different pump and valve models or manufacturers.

Research and development of more robust hydraulic components for use in contaminated environments.

Assessing the effectiveness of design modifications in improving contamination tolerance.

Product Advantages:

Provides a comprehensive evaluation of both hydraulic pump and valve performance and wear resistance in a single test setup under contaminated conditions.

Simulates the interaction of contaminated fluid with key components in a hydraulic circuit.

Essential for selecting pumps and valves that can reliably operate in hydraulic systems with expected levels of fluid contamination.

Helps validate component designs and materials specifically for resistance to wear and degradation caused by particles.

Provides objective, quantitative data on the long-term effects of contamination on pump and valve performance.

Supports research and development efforts aimed at improving the robustness and lifespan of hydraulic components.

Technical indicators:

1. Test medium: hydraulic oil

2. Temperature of medium: 10~80℃.

3. Test dust: ISO 12103-A3

4. Test pressure range: 0.5 ~ 6MPa

5. Test flow: 1~20 L/min

6. Purification cleanliness: -/12/10 (GB/T

7. Test tank volume: 40L

8. Execution standard: JBT 7857-2006

9. Equipment power supply: AC380V / 50Hz

10.Power of the whole machine: 5.5kW

在线联系供应商

Other supplier products

| Multiphase High - temperature and High - pressure Explosion Limit Tester | Product Information: 1. Designed with a modular concept to flexibly meet various testing requirements. 2. Allows for free editing of the experimen... | |

| Oil-Water Separation Tester | Applicable Standards: (1)ISO/ TS 16332-2006 Diesel engine diesel filters Fuel Water Separation Efficiency Assessment Method. (2) ISO 4020-2001 Te... | |

| Bone Cement Four-Point Bending Fatigue Tester | Standard YY/T 1429 (China): Specifies four-point bending fatigue tests for acrylic resin bone cements under quasi-static and cyclic loading. IS... | |

| Washing Fastness testing machine | G228B washing fastness tester is used for washing, dry-clean color fastness testing. Electric touch switch, LCD menu display, without mechanical co... | |

| Catheter bending resistance tester | Catheter bending resistance tester - Other test instrument - standard Product Information: Product introduction The tester is composed of a pr... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |