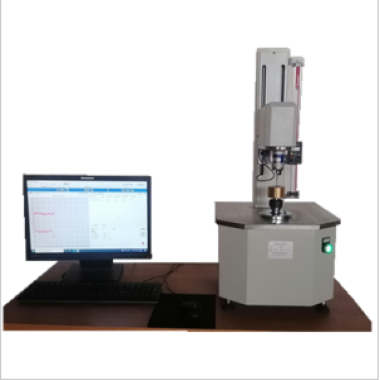

Face Mask Tensile Tester

The Face Mask Tensile Tester is designed to measure tensile strength, elongation at break, and related mechanical properties of various textiles and materials. The instrument integrates a motor with a speed control system, driving a synchronous belt deceleration mechanism and lead screw pair to apply controlled loads. It features a load measuring system and a deformation measuring system, with real-time display of control parameters and measurement results on an LCD screen. The tester provides overload protection, precise displacement measurement, and versatile testing capabilities for textiles, automotive interior materials, zippers, and leather.

Application

The Face Mask Tensile Tester is suitable for mechanical property evaluation across the following industries and products:

(1) Medical and Healthcare Industry: surgical masks, medical face masks, N95/FFP masks, disposable masks — tensile strength and elongation testing

(2) Textile Industry: woven fabrics, knitted fabrics, nonwoven fabrics, coated fabrics — tensile, elongation, and mechanical performance testing

(3) Automotive Industry: seat covers, interior textiles, leather trim, composite materials — tensile strength and elongation testing

(4) Leather and Accessories Industry: leather, zippers, straps, belts — tensile, tear, and adhesion strength testing

(5) Research and Development: development of new textile and mask materials, mechanical property evaluation, material comparison

(6) Quality Control: production batch verification, inspection of material strength and deformation properties

(7) Third-Party Testing Laboratories: certification testing, laboratory verification of textile and mask mechanical performance

The instrument is widely used for product development, production quality control, R&D, and laboratory testing.

Standards

The instrument complies with and can be applied to the following standards (including but not limited to):

(1) GB/T 32610-2016 – Technical Specification for Daily Protective Masks

(2) GB 19083-2010 – Technical Requirements for Medical Protective Masks

(3) YY 0469-2011 – Technical Requirements for Medical Surgical Masks

(4) GB 2626-2006 – Respiratory Protective Equipment: Filtered Particulate Respirator

(5) GB 2890-2009 – Test Methods for the Mechanical Properties of Textile Materials

(6) GB/T 16556-2007 – Testing Methods for Tensile and Elongation Properties of Fibers

(7) GA 124-2013 – Tensile Testing Standard for Protective Materials

Features

(1) Easy to operate, suitable for all users

(2) High measurement accuracy, certified by third-party testing organizations

(3) High-speed, low-vibration, low-noise motor drive

(4) High rigidity design, sturdy and durable

(5) Multi-language interface for international applications

(6) Automatic return to start position after test completion

(7) Automatic calculation of maximum force, minimum force, average force, maximum deformation, elongation, and tensile strength

(8) Supports tensile, bending, compression, folding, adhesion, tearing, peeling, and elongation tests

(9) Equipped with mechanical travel switch, emergency stop switch, overcurrent/overvoltage/undercurrent/undervoltage/leakage overload protection

(10) Software overload limit protection and breakpoint shutdown protection

Technical Parameters

| Item | Specification |

|---|---|

| Maximum Test Force | 100 N (optional 5000 N) |

| Operation Mode | Microcomputer, full Chinese menu |

| Measuring Range | 0 – 100 N |

| Accuracy Level | Class 1 / Class 0.5 |

| Test Force Accuracy | ±1% |

| Minimum Test Force Resolution | 0.001 N |

| Displacement Resolution | 0.01 mm |

| Deformation Accuracy | ±1% |

| Speed Regulation Range | 0.001 – 500 mm/min (infinitely variable) |

| Test Speed | 50, 100, 150, 200, 250, 300, 500 mm/min |

| Tensile Stroke | 700 mm |

| Overall Dimensions (L × B × H) | 540 mm × 280 mm × 1450 mm |

| Power Supply | AC 220 V, 50 Hz |

| Net Weight | 80 kg |

Accessories

Main testing unit

Synchronous belt and lead screw assembly

Load and deformation measuring system

LCD display controller

Sample clamps for textiles, masks, zippers, and leather

Power cable

Operation manual

Calibration certificate

Test Procedures

(1) Mount the specimen in the appropriate clamps

(2) Set test parameters: test force, speed, and tensile stroke

(3) Start the automatic test via the microcomputer controller

(4) Observe real-time force and displacement on the LCD screen

(5) Record maximum force, elongation, and other calculated values

(6) Repeat tests for multiple specimens or different conditions

(7) Clean the clamps and measurement area after testing

Maintenance Information

(1) Regularly clean clamps and lead screw mechanisms

(2) Verify calibration of load and displacement sensors periodically

(3) Inspect motor, control system, and safety switches for proper operation

(4) Keep the instrument in a dry and clean laboratory environment

(5) Maintain operation manual and calibration documentation for reference

在线联系供应商

Other supplier products

| Fiber Blend Ratio Test machine | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Bearing Friction Torque Measuring Instrument | Bearing friction torque is an important factor affecting bearing noise, vibration, and lifespan, and is a key indicator for measuring the dynamic p... | |

| Whole shoe breathability and heat preservation testing machine | Standard SATRA TM376: Thermal insulation testing of footwear with sock integration. SATRA TM386: Water vapor permeability assessment for athlet... | |

| Dental Implants Static Torsion Testing Machine | Standard ISO 13498: Specifies static torsion testing protocols for dental implants, including torque application rates, failure criteria, and data... | |

| Large diameter blasting test machine | The large-diameter blasting test machine can perform continuous (linear) pressure testing of pipes according to ASTM D 1599 standard. The pressuriz... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |