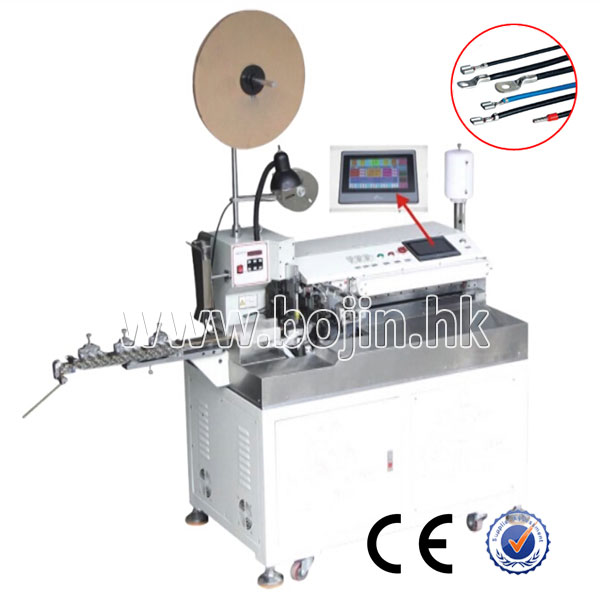

Fully Automatic Terminal Crimping Machine

The operation procedure of Full Automatic Crimping Machine

1. The operator must be trained to post the certificate for working;

2. Pre-operation refueling and machine check:

1) Refueling and conducting machine inspection for each action part, refueling according to the "maintenance and check" list of refueling;

2) Preheating operation (idle speed) :

① In order to stabilize the machine, please reheat for 5 minutes.

② Due to the solidification of oil in winter, please slightly lengthen the preheating time.

③ The operation mode during preheating is set to " idling mode".

④ If there are wires and molds, please remove them before running;

3. Attentions during working:

① Firstly, install the electronic wire on the machine host;

② Prepare the terminal and mold, and install them on the press machine;

③ Set the cutting length of the wire and the length of the stripping and confirm them;

④ Move the electric wire to one side of the press and the pressing position of the mold.

⑤ Confirm the pressure state (position, etc.) by the manual operation for crimping, if it is not fit, modify the processing data and adjust the operation of pressing height, and repeat the operation after ④;

⑥ Step by step, return the wire back to its original position, sending the wire through the feed switch to confirm the shape and height of the pressure.

⑦ Move the wire to side2terminal crimping machineand mold crimping position.

⑧ Confirm the pressure state (position, etc.) by the manual operation for crimping.

⑨Cycling operation and confirm the processing state of the product. If there is no abnormality, extract the electric wire in the machine by the EJECT mode.

⑩ Set the production number, start producing and performing the visual inspection.

在线联系供应商

Other supplier products

| BJ-1200 Pneumatic Crimping Machine | Specification ofBJ-1200 Pneumatic Crimping Machine Model: BJ-1200 Crimping range: non-insulated terminals≤10mm² Pre-insulated terminal... | |

| MS-1100 Electronic Tape Dispenser | Specifications ofMS-1100 Electronic Tape Dispenser Safety guard system prevents activation of cutter when foreign objects are present Will incr... | |

| Labelcombi-100 Label Sticker Dispenser | Features ofLabelcombi-100 Label Sticker Dispenser The smallest area occupation, becomes to everywhere with its pretty and class design for stick... | |

| AL-937B Auto Label Rewinder | Features ofAL-937B Auto Label Rewinder Label winding machine Automatic speed sync and tension control, without any adjustments. Wind inside ... | |

| BJ-08T Wire Twisting Machine | Product features ofWire Twisting Machine BJ-08T Axis design, while standing! Greatly improve production efficiency LCD backlit display, modern ... |

Same products

| The Ultimate Tool for Bubble-Free Displays | 卖方: 深圳市维客修科技有限公司 | FORWARD FW-16R除泡机、FW-8R迷你除泡机,在手机、iPhone、iPad、平板屏幕翻新过程中,去除屏幕OCA气泡,最大支持12.9寸屏幕。安全门设计,24V低压风阀配置,有效降低... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | 卖方: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | 卖方: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | 卖方: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | 卖方: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |